NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Does the head have a threaded CHTS boss, between #5 and #6 (approximately)? That's the simple indicator for MN47, the 280Z N47 doesn't have it. Don't know if you can get to 37 from 44 without welding. The MN47 is about 38-39, from past posts I've seen (from jmortensen and others), so 37 is about a shaved MN47.

-

I would check all of your timing associated items. Make sure you really know where TDC is, degree the cam, don't use a hole in a sprocket, verify that the MSD program is actually creating those advance numbers (the curve you showed is what's supposed to happen, but might not be what is), that kind of stuff. There have been a couple of posts recently from people who got cams that din't match the profile cards. Not sure where they ended up. You might not even have the cam profile you think you have. Don't trust - verify.

-

Not an expert but the shape of your torque curve shows a steep drop at 5800 RPM. Seems like it might be a sign of just not enough air flowing in to the cylinders. Choked off somewhere in the path. Probably obvious, but I thought I'd go ahead and state it. If I read your timing curve right it shows 6 degrees pulled, from 35, so 29 degrees total advance at 6500 RPM. 26 total at 5000, and 25 at 4000. Most L series tuned for power are set to max advance are 34 at 2500 and above, thereabouts, from what I've seen. So timing seems retarded, overall. Might just need a few tweaks and some more tuning. You only gave two numbers on the cam profile, bit didn't indicate if it was degree'd properly or maybe it was just put on a timing chain sprocket notch number. Just another small detail. Seems like the cam profile should push much higher. A comparable Schneider cam shows a 3500 - 7500 working range (however they figure that). http://schneidercams.com/dastsunL6_NA.aspx

-

Nobody from that club on the site? Anyone know any of them? https://web.archive.org/web/20160707184806/http://www.atlanticz.ca/index.php/aboutus/executive.html

-

You could chuck the pallnet rail up in a lathe and turn the sections between injectors down so it looks like tubing. Once you add up the cost of injector bungs (caps) and rail and machine work you'll see why the pallnet rails are a pretty good bargain. Don't forget that the injector "caps" have to withstand fuel pressure, they'll pop off. Even that copper rail needs a clamping/mounting system. What looks simple actually gets complex before you can use it. Good luck.

-

Did you build the engine? Is it new, used, old? More engine info.

-

I've got a set from a severely abused 5 speed. Somebody like duragg could probably file the dog teeth back in to shape. Maybe you're at that level? Don't know if it's worth a shot or not, they'll probably grind otherwise. I get up north now and them and could drop them at at your favorite shop, maybe. Duragg might also have a good set. He ran through a few transmissions I think, before he moved on to better equipment. He seems to wander by the forum occasionally. Worth a message. http://forums.hybridz.org/topic/110792-high-rpm-shifting-dynamics/

-

Go to Autozone or similar and look at their pre-fitted, straight, coated steel fuel line repair tubing. With the right fittings it might give you what you want. You mentioned "caps" but barbs are era-correct. Same vein - what are you trying to change? Why not use the stock shape?

-

Odd looking bracket on my 280z, any ideas?

NewZed replied to Jaymanbikes's topic in S30 Series - 240z, 260z, 280z

It's a stock factory piece installed on all 280Z's from the factory. They just made it ugly. It's shown in the Rear Axle chapter, twice, but the illustrations are poor. "Damper plate". -

Ignition signal from engine compartment to tach...

NewZed replied to marinez's topic in Ignition and Electrical

I don't know what means. But, good luck with it. I have a GM HEI system, module and coil, on my L6, using the 280Z VR signal. My tach doesn't work without a condenser on the negative terminal wire. -

Ignition signal from engine compartment to tach...

NewZed replied to marinez's topic in Ignition and Electrical

There's a tach output terminal on the typical HEI distributor from what I see on the old interweb. It's probably just a branch from the coil negative post. Easy to check. -

Ignition signal from engine compartment to tach...

NewZed replied to marinez's topic in Ignition and Electrical

With the key On you should see battery voltage at the tach end of the wire if it's connected to the coil negative terminal as it should be. The 280Z tach just counts the voltage pulses on the negative post of the coil as the coil charges and discharges. -

Ignition signal from engine compartment to tach...

NewZed replied to marinez's topic in Ignition and Electrical

Do you know what the signal is? Did you measure voltage at the tach end of the blue wire? Have you looked at the wiring diagram? Really, the basics are pretty easy with a meter. Get everything connected correctly, then you can focus on why the needle doesn't move. With a meter you don't have to worry about what the terminals look like. Who recalibrated your tach, and is it the stock 1975 280Z tach? Are you using the stock 280Z harness connection at the tach? Aftermarket tachs can have different wiring schemes. -

You really want just a one piece L6 dust plate for a manual transmission. The E and the T don't really matter. "ET" might throw some people off. And Nissan calls it an end plate or rear plate, for any internet searching.

-

Is this going to be streetable or just something to rip around the corn fields in? 1979 280ZX's have several possible differentials, from a 3.36 R180 to a 3.7 R200. An R180 might not last long.

-

Ignition signal from engine compartment to tach...

NewZed replied to marinez's topic in Ignition and Electrical

No hug? You need to add some detail. There are some considerations and some simple tests you can do. It's not even clear what you mean by nothing. Could mean no blue wire, could mean blue wire doesn't work. Could be the resistor fell out. -

280zx turbo ignition control module swap

NewZed replied to rickyellow zee's topic in Ignition and Electrical

Thanks. With the technical detail you've added a person might be able to get one of these to work. $8.50! For those on a budget. Probably need some added protection from the elements though, I'd guess. Not an expert, just like to solve puzzles. Messing around. Hopefully, somebody will come back and confirm a swap, although the HEI module swap is already well-proven and cheap. https://www.diyautotune.com/product/bosch-bip373-coil-driver-mod-kit/ https://www.diyautotune.com/support/tech/other/bosch-bip373-ignition/ https://www.diyautotune.com/downloads/products/bip373/bip373_datasheet.pdf -

Ignition signal from engine compartment to tach...

NewZed replied to marinez's topic in Ignition and Electrical

Brown, green and red would be the VR sensor wires that run to the ignition module in the cabin. The blue wire from the coil negative terminal (through the ballast) is the tach trigger. -

280zx turbo ignition control module swap

NewZed replied to rickyellow zee's topic in Ignition and Electrical

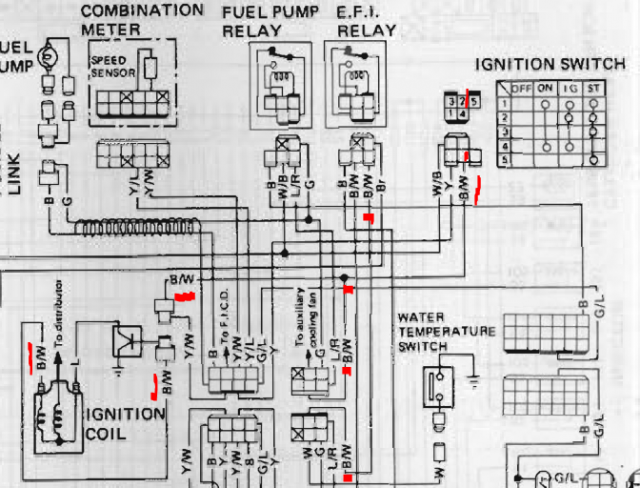

When I look at the diagram I don't see that. I see L (coil negative), ground, and Y/W (trigger Pin 5) as the three power transistor connections. B/W also supplies the EFI relay. Oh well. Good luck future experimenters. Page EFEC-98 1983 FSM. -

280zx turbo ignition control module swap

NewZed replied to rickyellow zee's topic in Ignition and Electrical

I don't know that the swap will work as I showed, but the ignitor is after the coil negative, with no positive feed, according to the 1983 wiring diagram. So, not sure if you're mis-remembering the above. I just compared diagrams, the 1983 diag. is Post #14 above. The HEI is a "smart" module, which does current-limiting, aka dwell control. Maybe the 12V feed is involved there. Or the zero-crossing trigger circuitry, for use a VR sensor. It has much more functionality than is used when it's wired up as a power "switch". Overkill and just lucky, really, that it works. -

Disappointing conversation with CustomPlenumCreations

NewZed replied to Brad-ManQ45's topic in Nissan L6 Forum

Your basic problem is that you're ready to argue intake manifold and engine theory with CPC but you are far from being an expert. You're bringing a load of internet "knowledge" and turbulence in to his shop and, obviously from this thread, will be ready to blast his work on the internet if the internet theory doesn't pan out. Considering all, he seems like a smart businessman. He's thinking long-term, not quick easy money. Your displeasure would have more weight if you had tried other shops and CPC was the only one that refused. Shop your proposal around and see who bites. -

The halfshafts should be Spicer 51505X, I think. Can't find a propeller shaft number. You should call them. Ask for James, he seems to know what's going on. You can get the halfshaft Spicer u-joints at most parts stores, if you're in a hurry. They're fairly common.

-

Could be you got 240Z propeller (aka drive) shaft u-joints instead of driveshaft (halfshaft) u-joints. I think that they're different sizes. You should give the part numbers of what you're working with. Might offer a clue.

-

No, I mean in terms of what you said you were trying to do. As far as the thread shows you still have your 1975 alternator with external regulator. The run-on problem is not a big deal, the least of your worries. Down at the bottom of the atlanticz page the diode solution is described. It's actually described all over the internet, on various Z car forums. The atlanticz page is dead now anyway.

- 15 replies

-

- Alternator

- Pulley

-

(and 4 more)

Tagged with: