NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Not a bad idea. The 1978 280Z rail is also a direct swap, and one piece. 75-77 are the three piece rail that you have now. The ZX rails will swap but the cold start valve tube will need some bending. Nissan redesigned the intake manifold for the ZX's, although 1979-80 is a transition period for the L28 engine. Not sure what they did for intake there. They can all be made to work.

-

Maybe a 200SX or 240SX? The front mounts look similar, small holes in small ears. The CV style looks early 80'sish, 3x2 holes. http://www.the510realm.com/viewtopic.php?t=22269 Get the ratio and see if it's open or VLSD. I don't think that it would be CLSD. Probably an open diff installed for the ratio.

-

And odds are good that the crud in the tank and lines came from water in the fuel. If it got through the filter, the injectors could be rusted. They're sensitive. The injectors are easy to remove as an assembly still attached to the rail. Don't miss the bracket held on by an intake manifold bolt. That's the cause of many bent fuel rails.

-

Where are your fuel pressure measurements? Between the filter and the rail.

-

Off centered 75 280z steering rack....hmm

NewZed replied to marinez's topic in Brakes, Wheels, Suspension and Chassis

You should to be able to find one out on this side of the slag pile. If shipping is huge. -

"L" means blue in Nissan diagram world. 76 still used a ballast resistor, with a start circuit and a run circuit. Your area of interest starts at lower left. http://www.atlanticz.ca/zclub/techtips/wiringdiagrams/76_280z_wiring.pdf

-

Follow the circuit. If Pin 1 doesn't have voltage it's either not connected to the coil negative terminal or the coil isn't getting power. Or the coil is bad. I believe the wire at the coil is blue.

-

Have you checked Pin 1 for voltage with the key On?

-

Off centered 75 280z steering rack....hmm

NewZed replied to marinez's topic in Brakes, Wheels, Suspension and Chassis

Why not put a tape to it first? If the rails are bent, a stock member won't fit anyway. -

Disappointing conversation with CustomPlenumCreations

NewZed replied to Brad-ManQ45's topic in Nissan L6 Forum

Read the last post in the Hybridz thread you sent him and you can understand why he backed off. You went to someone who considers himself somewhat of an expert in the field and dumped a large load of other expert opinions in front of him, EMPHATICALLY stated, that are the opposite of what he advertises on his Facebook page.. Who would want a piece of that? -

Off centered 75 280z steering rack....hmm

NewZed replied to marinez's topic in Brakes, Wheels, Suspension and Chassis

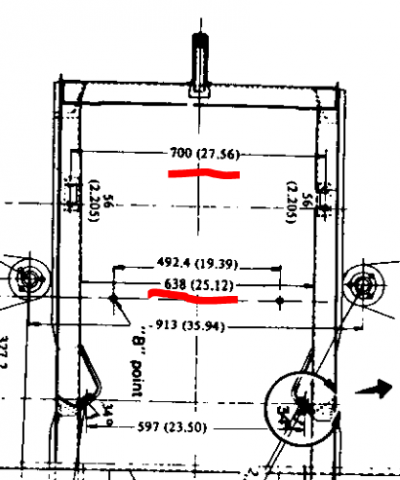

I would take some measurements and see what you're dealing with. Maybe somebody repaired a damaged crossmember. I underlined two simple ones, one between the rails and one to the crossmember mount bolt heads. -

Off centered 75 280z steering rack....hmm

NewZed replied to marinez's topic in Brakes, Wheels, Suspension and Chassis

Weird. Did somebody do some funky body work under? Is that even the stock 280Z crossmember? You might open up the Body chapter and take some measurements. -

Disappointing conversation with CustomPlenumCreations

NewZed replied to Brad-ManQ45's topic in Nissan L6 Forum

He's probably seen the discussions about Sensa Pari and is avoiding any Hybridz association. The OP probably could have had one made but he might have referred to the JeffP thread and ruined his chance. Ariel/ISL33P never came back with the flow numbers in that other thread. His business, and the Sensa Pari fiasco, shows that there's a demand out there. Ron Tyler and BRAAP's work showed that bolt-on performance for the L6 is not easy. Lots of L series engines over there, seems like somebody would have done one already. -

Off centered 75 280z steering rack....hmm

NewZed replied to marinez's topic in Brakes, Wheels, Suspension and Chassis

-

Disappointing conversation with CustomPlenumCreations

NewZed replied to Brad-ManQ45's topic in Nissan L6 Forum

I'm cynical in general, especially with the old internet making it so easy to create an image from nothing. The CPC Facebook page looks just like the Sensa Pari stuff. Cut an old manifold, install a neat-looking plenum. It is odd though that they wouldn't even talk about taking your money. Could be that they're just managing their customer base. You're not what they're looking for. -

Disappointing conversation with CustomPlenumCreations

NewZed replied to Brad-ManQ45's topic in Nissan L6 Forum

If your business model is based on creating an image then controlling that image is important. If they build your custom manifold and the wrong person gets hold of it later, they could spend their time explaining why the ports don't match. "Look at these CPC ports man, they don't even match!". Much easier to make a shiny manifold with good welds and matched ports. Everything "looks" right. It's not about performance, it's about appearance. I've seen the reversion discussions and they make sense in certain applications. These CPC guys might know also but just don't want to deal with it. Or they don't really know and are just sticking with what looks right. Sensa Pari was just a welder with an artistic flair that stumbled in to a pile of easy money. He couldn't even get his parts to bolt on correctly. -

Disappointing conversation with CustomPlenumCreations

NewZed replied to Brad-ManQ45's topic in Nissan L6 Forum

How are these guys different from that Sensa Pari guy? Jeff P has one of his manifolds, still waiting for his review.. There's no performance information or theory on the CPC Facebook page, just a bunch of comments about nice welding and how good they look. Do they have a real performance history or are they another show-performance company? Seriously, wondering... -

Disappointing conversation with CustomPlenumCreations

NewZed replied to Brad-ManQ45's topic in Nissan L6 Forum

But you understand Jeff P's? -

Disappointing conversation with CustomPlenumCreations

NewZed replied to Brad-ManQ45's topic in Nissan L6 Forum

You forgot to add the little emoticon. To show you're being ironic. -

You were so close. You can't really take an uppity tone when the answer was right there, and you almost had it yourself. It was the "wrong" pulley for the timing tab, and, by some definitions, it was a hack job. Pretty clear.

-

Off centered 75 280z steering rack....hmm

NewZed replied to marinez's topic in Brakes, Wheels, Suspension and Chassis

You could follow the instructions in the Steering chapter. Apparently there are two "punch" marks. -

Transmission crossmember frame nut possibly crossthreaded?

NewZed replied to Stunt's topic in S30 Series - 240z, 260z, 280z

You're just planning way too much cutting and welding. Cut a 2x2" piece out and weld in a new one. They can even fabricate a new floating nut. Or cut the floating nut piece out of the parts you've bought or are planning to buy if you just have to have original Nissan parts. Find a friend who has some real mechanical skills who can look at it and give advice. If you go in to the wrong shop with this problem they're going to milk you for hundreds or thousands of dollars when they realize that you don't know much. Only being blunt to save you some money and future problems but you're on the verge of making a big mistake. This would not even be considered a real problem for most of the people on this forum, just a simple activity, maybe an hour's worth of time. No offense. You're in over your head. You're on the right forum though, if you can just take the advice. -

Weren't you installing one liner so that you could keep the other five as-is? Now that you have four bad, you're in simple bore all six and get new pistons territory. Probably cheaper than four liners and keep the pistons. Might be time to stop and calculate. Four liners, keep pistons = X $. Bore all six, get new pistons = Y $.

-

Bummer. Seems like removing a groove from a double row might be an option. Why do you need single? This guy might have one or could rebuild. Good luck. http://www.datsunstore.com/crank-pulleys-7083-rebuilt-turbo-p-652.html

-

Transmission crossmember frame nut possibly crossthreaded?

NewZed replied to Stunt's topic in S30 Series - 240z, 260z, 280z

You could just take a hole saw and cut a circular piece out. Seems like you're overthinking the problem. I'd take it to a body shop and let them recommend a fix. They're used to working with sheet metal and structural elements. It's not complicated for somebody who works in the field.