NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

MSA has two options. http://www.thezstore.com/page/TZS/PROD/classic12d02c/10-2139 http://www.thezstore.com/page/TZS/PROD/classic12d02c/10-2138

-

That's considerate. But there are probably 50+ threads on this forum alone with your almost exact problem description (except for the 2 psi number). One more won't hurt though. Not sure how a relay swap fixes "no pulse". Unless there's no power to the injectors. That can be checked with a meter. Good luck. The clutch problem probably has 100+ threads. You're surrounded by ghosts.

-

That might have been me who commented about the tachometer. I've seen it twice with stock ignition systems but my 76 car, currently, with a GM HEI ignition module doesn't do it now. So it's unclear. It might be a problem but it's not guaranteed. There's a simple test you can do to see if the injectors are being triggered. Connect a wire to the coil's negative post. Leave the other end dangling free. Turn the key On. Quickly tap the wire to a ground point. A spark will be created at whichever spark plug is in line with the rotor. Every third tap should fire all six injectors. The tapping is mimicking the ignition module and the ECU sees the sparks and responds on every third tap/spark, a full revolution of the engine. If you get injector firing don't worry about the tach. If you don't you'll have to figure out why. You might be trying to do too many things at one time. With the EFI system you can check each component individually, and as assemblies. Read the Engine Fuel chapter to understand how the fuel pump gets its power, and when.

-

You already showed that the motor does "turn" and also "fires" if you add gas. It's turning. You haven't said or shown that you know the injectors aren't opening. If they did open what do you think the difference in quantity of fuel will be between 2 psi and 36 psi? Your title is on track - "not getting fuel". The most likely cause is low fuel pressure. The test procedures for the injectors and the fuel pump and much more are in the Service Manual.

-

Proper fuel pressure is very important. 2 psi is not right.

-

-

"Stock" 280Z EFI systems won't handle a turbo well. People do it but it takes some in-depth engine management knowledge to make it work. If you take it to a shop they won't know how to make it work either. You are in over your head, there's no easy way. You could just leave the turbo disconnected and use the 280Z EFI system to run the engine. It will just be a low CR L6 engine. Drivable with much less chance of blowing up. Seriously, there's much more involved than what type of connector to use.

-

Why wait a week? There's all kinds of special you need to know. Check bunblezee's thread. You haven't said what engine management system you'll be using. http://forums.hybridz.org/forum/90-l-series/ https://www.google.com/search?q=Needing+some+wiring+help+with+l28et+swap&rlz=1C1CHFX_enUS584US584&oq=Needing+some+wiring+help+with+l28et+swap&aqs=chrome..69i57&sourceid=chrome&ie=UTF-8

-

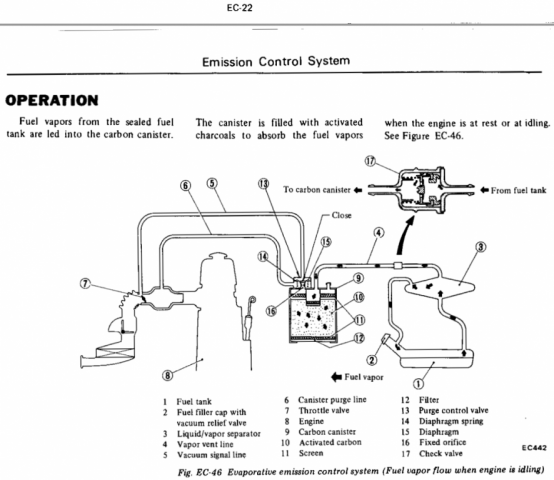

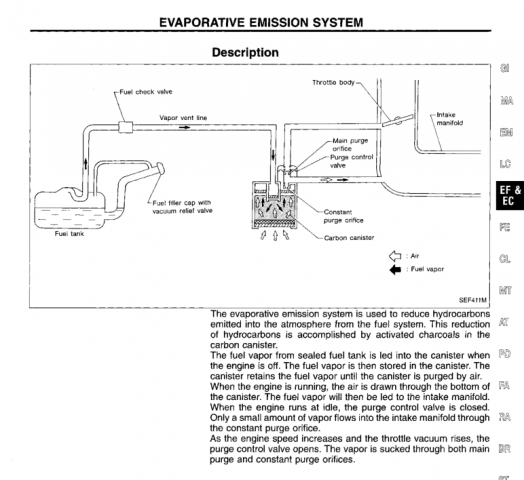

Nissan did essentially the same thing from 76 to 95. Lost the liquid/vapor separator or incorporated it in to the tank by 95. Some hose, a check valve and a carbon canister, plus the correct fuel filler cap, and you should be able to rig something up. There was a thread a while back about how the newest cars have a pump to the tank to pressurize it, the tank itself not the fuel line, to a certain low level. Thought it was crazy, but it's true. Could be the for anti-cavitation as Tony D described. Edit - actually it appears to be just for system-checking. But, who knows for sure. http://www.obd-codes.com/p0453 Diagrams from 76 and 95, 280Z and 300ZX.

-

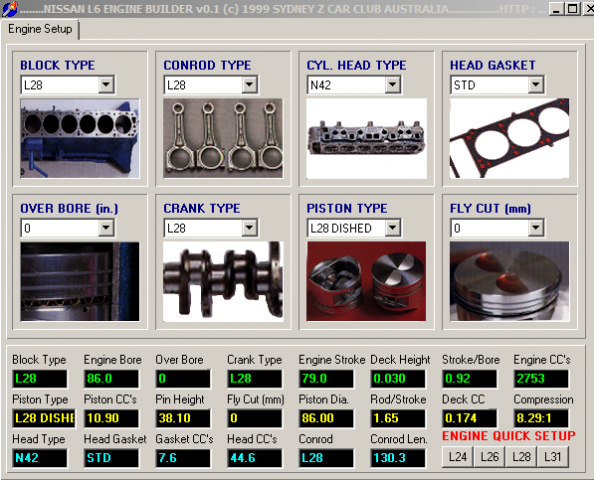

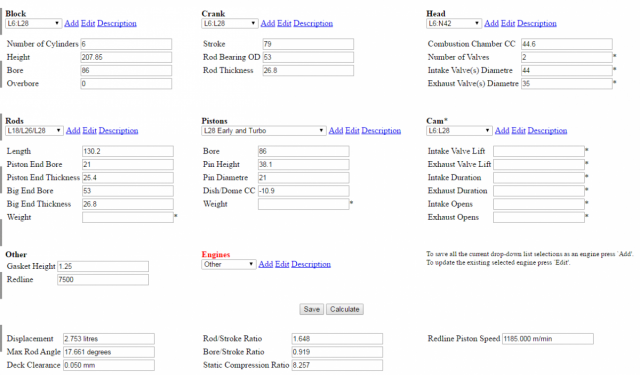

The Hybridz calculator is a bit higher than the Ozdat. Dished and flat shown. The 10's probably come after a shave.

-

Seems to give very close numbers for the stock configuration though. Implying that the calculator equations are correct. 280Z engine, dished pistons, 1.25 mm HG, 8.3 CR.

-

280z rear strut insulator

NewZed replied to tyranie909's topic in Brakes, Wheels, Suspension and Chassis

There was a guy on the forum who had a similar problem with adjustable struts cut too short. He built an adapter to take up the space. Basically a piece of pipe with a flange on each side. -

Might as well to that, the matter of degree - just welding, or welding and shaping, welding/shaping/porting, welding/shaping/porting/flow testing to a specific number, etc. I remember reading about a guy who taught welding and raced L series engines. He reshaped the intake ports in to the valve cover area via added metal to raise the port floor and give a more direct path to the valve head. Had to build a new valve cover to fit it, it was that high. You can go pretty far if you want to. Might be in the How To Modify book.

-

Never mind.

-

The first video here shows the engine.

-

Easy to get lost in what's going on.

-

Stock Car Mafia's '78 280z LS2 Build

NewZed replied to Stock Car Mafia's topic in S30 Series - 240z, 260z, 280z

Have you studied the fuel systems of the cars the VG33 came in? Seems like the "hot start" problems with the L28 were mostly from the design of the engine, with injectors next to exhaust manifold. The L6 engine is a carb design retrofitted with fuel injection. The VG33 doesn't normally have hot-start issues in the cars it's used in, does it? It's an EFI design from the beginning. -

Or....the wiring wasn't right.

-

Rota Grid - not snug on the hub - 78 280Z

NewZed replied to repenttokyo's topic in Brakes, Wheels, Suspension and Chassis

The same question was asked and answered in the first two posts, with details following. Take a measurement and see if the hub will fit in the hole. -

The oil pump shaft could be a few teeth off which would offset the distributor drive spindle, and a PO moved the ignition wires to make up for it. Check the position of the distributor rotor when #1 is at TDC n compression stroke. Easiest to do by removing the valve cover and looking at the notch and groove and the cam lobes. Basically, just go through the engine assembly procedure and see what lines up and what doesn't. The mark on the pulley is there for when everything else is assembled a certain way. Could also be that you just have a different pulley. Get a passenger side timing tab, bolt it on and see how thing look then. Worst case, your damper is failing.

-

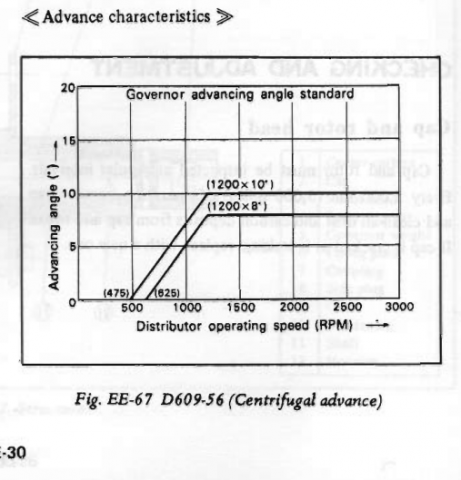

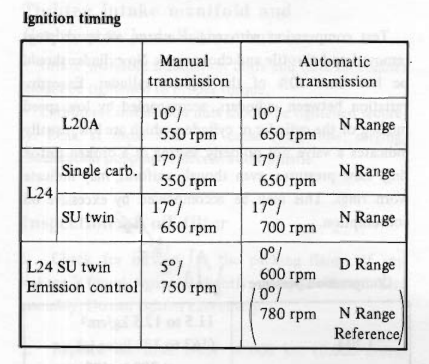

That would be the end of advancement, not a switch. Sloping upward from the base setting as RPM increase. 4000 RPM seems high for the L6, most of them are done by 2500. Since you have a timing light you should just characterize what's happening. Set the base to some low number, then rev the engine until it stops advancing. Note the timing and the RPM. If you don't have a dial back light you can set timing to zero for a short while and rev the engine until advancement stops. Then you'll have the centrifugal advance amount, which you can use to set base timing. Here's an example of a timing curve. It's in distributor RPM, not crankshaft so you need to double the numbers to use them at the crankshaft. So advance starts at 1000 RPM (500), and stops at 2400 (1200), with a total of 20 degrees (10), for the first curve. So, if you set your base to zero with that distributor, to characterize it, it would stop advancing at 20 degrees on the timing mark, at 2400 RPM. I'm not sure which distributor goes with which carb setup (there were several combinations in 1972), but there are other curves in the FSM. Read Engine Electrical and Engine Tuneup if you want to see the possibilities. They have high centrifugal advance for low base timing, and low centrifugal for high base timing. Generally, they limit total to the low 30s. Most guys on this forum shoot for about 34 total.

-

Base timing is set at idle speed. Centrifugal advance adds timing as RPM increase, typically about 20 degrees. So if you set base at 28, you'll have 48 at about 2500 RPM (typical max advance), which is too much. Add vacuum advance on top and you could have up to 66 degrees advance at high RPM, low throttle opening cruising. Which would be ridiculous. Base timing should be set to about 10 degrees, normally, if vacuum advance i used. If it's not then about 20 is typical, depending on total centrifugal advance. This is common to all distributors, not just the Kameari. You can characterize what you have completely with a dial-back timing light, or some tricks. You haven't really described what have very well though. 28 degrees under what conditions? Idle, with vacuum hose, high RPM?

-

Transmission crossmember frame nut possibly crossthreaded?

NewZed replied to Stunt's topic in S30 Series - 240z, 260z, 280z

p.s. you might find a twelve point socket that will fit your tap also. Then you can use normal extensions and a ratchet drive to turn the tap. The ratchet is nice because you can focus on keeping it straight and turning small amounts, in small spaces. -

Transmission crossmember frame nut possibly crossthreaded?

NewZed replied to Stunt's topic in S30 Series - 240z, 260z, 280z

I think the OP is psyched out and assuming that this is a difficult job and he will fail. Hence the blanket "I failed" statements, with no details. Needs to change his mindset and assume that he will succeed. The JB Weld might be used to hold the nut in place so that he can use his drill and tap more easily. Apparently the nut is moving around causing him problems. So a dab or two of JB Weld to hold the nut might help out. Get the right holder for your tap or make up your own. Getting the tap started straight is your problem here. Trying to use a bulky cordless drill as a handle won't work. Guys that do much tapping probably use their fingers and a tight grip to start the tap, then a wrench to carefully advance it. You have to be very aware of how you're twisting the tap, no side loads, just rotation. It's difficult if you haven't done a few. One trick you can use to make a tap handle extension, if the tap is the right size, is to use a socket upside down, with an Allen wrench in the socket where the nut or bolt head would normally be. The tap goes where the wrench socket drive would normally be. It works with 1/4" and 1/2" drive taps. The other odd sizes are more difficult. -

Here's one, different transmission but similar dilemma. Cut and weld. The 280Z's have a nice set of mounting ears, why waste them. Maybe get a 280Z crossmember and blend it with a Z32's. Use the Next and Prev buttons. http://www.motortopia.com/cars/1973-datsun-240z-11118/car-pictures/240sx-transmission-swap-14041/IMG_2170JPG_Thumbnail1.jpg-269044