NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Never mind, I just went and looked at one and your rear seal seat is broken. The welder guys probably know for sure but welding might damage the slip yoke bushing area or warp things. Just brainstorming, you could probably fabricate a ring around the remaining case, maybe a machined aluminum ring that presses on, then fill fill the inside with JB weld to do the sealing. You could even install the seal and fill the gap. Or cut the remainder off at the base of the break, fabricate an aluminum ring with a seal seat, and press it on. Luckily you still have a machined surface to attach to (marked it in red on your picture). I could see a two step ring, one to the housing outer diameter and one to the seal diameter. Heat it, press it on, and your seal seat is back. No welding. It could be cut on a lathe. It would add a little bulk but be barely noticeable.

-

Looks like the rear seal still has seat area. The part that broke is really just dust shield material. You could probably fabricate a plastic piece that presses over, from a piece of pipe. Or just run it as-is. You said shaft in the text but I think that you meant case like in the title.

-

You can take a jumper wire from coil (-) and tap it to ground with the key On. That will cause a spark from the center wire if it's close enough to a ground. Are you trying to figure out why your engine won't start or just being very thorough? You might just have a bad module.

-

How to Bleed 280Z Clutch Master Cylinder by Yourself

NewZed replied to SubaruBRZ's topic in Trouble Shooting / General Engine

It's bolted to the transmission, in front of the clutch fork. You can see it if you look down behind the starter from the engine bay. The clutch hose is connected to it. The starter is below the battery. The battery is on the passenger side of the engine bay. Under that cover. You might leave the Google and open the FSM, Clutch chapter. Lots of good pictures and advice in there. http://www.nicoclub.com/datsun-service-manuals If you're trying to refill and bleed old crusty master and slave cylinders you might be wasting your time and fluid. They tend to corrode inside easily and blow seals. Worth a shot though. -

Yes, with no current flowing the + and the - of the coil will read the same voltage, battery voltage, to ground, with the key On. Just measure at the terminals of the coil, with everything connected. Hook it up like your picture and it should be ready to start.

-

How to Bleed 280Z Clutch Master Cylinder by Yourself

NewZed replied to SubaruBRZ's topic in Trouble Shooting / General Engine

I screwed up and thought you were doing a brake master cylinder. The clutch master cylinder doesn't really need bench bleeding. It doesn't even have a bleed screw like the brake cylinder. The clutch system will almost gravity bleed itself. You can bleed it by finger from the slave cylinder. I think that's how I did mine once. Open the bleed screw and push the piston in with your finger. Tighten the screw and let go, and it will draw from the reservoir. Do that several times until you see clear fluid coming out. Kind of like a vacuum bleeder, but using the slave cylinder piston spring. I also have an old shovel handle that is perfect length for pressing the pedals and jamming against the seat. That works too. -

All I'm saying is not that close to mimicking 100% ethanol. It probably gets you on the curve, but you'll be extrapolating instead of interpolating.

-

You're showing a blue wire in your drawing from the coil negative to the tach. Is that the Blue that gets no voltage above? If so, that would mean you have an open circuit in the coil. The coil is bad. With the key On and engine off, voltage should be the same on positive and negative sides of the coil. But you need to measure it with the wire attached to the coil negative, not disconnected. Power IS getting to the coil on the BL and BW wires. Otherwise, everything looks correct in your picture It should work like that, with a good coil. don't forget to make sure the distributor body is well-grounded also. That's where the current goes after it passes through the module.

-

How to Bleed 280Z Clutch Master Cylinder by Yourself

NewZed replied to SubaruBRZ's topic in Trouble Shooting / General Engine

Run a clear tube from the bleeders on the side of the MC back up and in to the reservoirs. Pump brake pedal until you can't see any more bubbles. If the MC is old it may have corrosion at the end of the piston's travel that could damage the seals. Beware. -

Isopropyl alcohol and ethanol shouldn't be comparable in combustion terms, as an "E" ratio fuel. Three carbons versus two. Is that somebody's guess, along the same lines that people poison themselves with to get a buzz, or is there some basis?

-

This kind of implies that you didn't dig very deep in to the Factory Service Manual so may not have diagnosed the right problem. There is an excellent schematic of the relay in the Engine Fuel chapter. Back to diagnosing though, have you done the basic relay test of closing the AFM contact switch with the key On and listening for the pump? That's what triggers the relay. Check for power at the AFM switch to be sure that portion of the path is there.

-

For some reason Nissan completely overlooked showing or describing the ports on the bottom of the throttle bodies. Ported vacuum is what the factory used. I think that at least two of the bottom ports are ported (only get vacuum when the throttle is off-idle). One is for the BCDD and the other for the distributor advance. You can use your finger to find one, just feel for suction with the engine running, throttle open and closed.

-

The L28ET uses a CAS and ECU timing control. 84 Nissan Patrol L28E--->L28ET in progress http://www.patrol4x4...holland-314225/

-

260z clutch slave cylinder home position?

NewZed replied to 882993md's topic in S30 Series - 240z, 260z, 280z

I completely overlooked the fact that you pressurized with air. You're just off on a trail of odd actions. Making life complex. Really not much to discuss. -

How do you know it's cold?

-

260z clutch slave cylinder home position?

NewZed replied to 882993md's topic in S30 Series - 240z, 260z, 280z

Don't forget to consider material relaxation and temperature changes as you try to solve this "problem". You might extend your experiment time out beyond 15 minutes also. See if it levels out or goes to zero. Seriously, it's a good observation, but might not actually be a problem. -

260z clutch slave cylinder home position?

NewZed replied to 882993md's topic in S30 Series - 240z, 260z, 280z

Seems like you're about to spend a lot of time on a specification that you made up yourself. -

Stream of consciousness writing, Thoughts as they come to mind. It is what it is. No rules broken, no usable information given either. Looks fun. Interesting story. Not sure what to do with it. Some details are janky, like LSD from a 280Z. Build on it and see where it goes. Welcome.

- 7 replies

-

- epic long first post

- sbc

-

(and 2 more)

Tagged with:

-

77 280Z - Looking for cost effective power

NewZed replied to jareddbh's topic in S30 Series - 240z, 260z, 280z

On the other hand, you could just do it and if it don't work well, go ahead to Megasquirt or similar. As far as basic power gainers, most say a better exhaust system and head work are the two biggies. There are many threads out there that started with your same question. There's probably even a thread in the FAQ's. Check the L Series forum at the top. http://forums.hybridz.org/forum/90-l-series/ -

77 280Z - Looking for cost effective power

NewZed replied to jareddbh's topic in S30 Series - 240z, 260z, 280z

The factory EFI system is pretty crude. Read the Engine Fuel chapter. It's designed to give driveability and emissions at mid-throttle, mid-range RPM, then adds a bunch of fuel at the high end. You can add more fuel for the high end to take advantage of your modifications, and run rich and dirty on the low end, or you can leave fuel as-is to run clean on the low end but run lean at the high end. That's the basic problem. You can add or remove fuel everywhere, but no adjustability in between. Your 77 doesn't even have an O2 sensor. Besides that $1000 won't get you far. The small stuff will eat it up. Make a detailed list of everything you'll need, including gaskets, sealant, new studs, etc,. just for the head work and the actual installation and see if you can even do that for under $1000. -

260z clutch slave cylinder home position?

NewZed replied to 882993md's topic in S30 Series - 240z, 260z, 280z

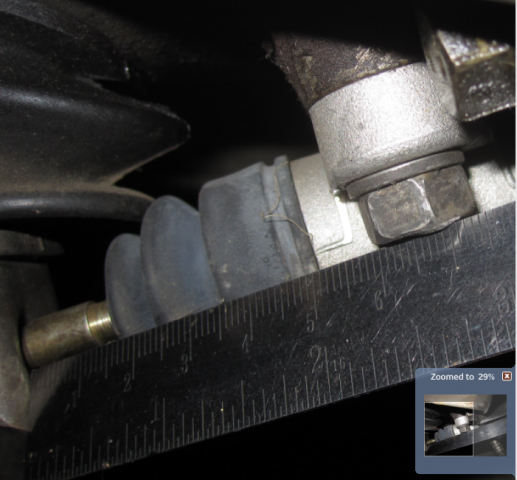

Here's a picture I took of a working clutch, at rest. On your leak-down problem - there are two seals in the MC; one to build pressure and one to keep fluid in the reservoir (check a later FSM, like 1978, to see a better diagram). I don't think that the MC is meant to hold pressure like a brake MC. It's meant for short time frames. Could be though that you have a leaky one. Quality is poor these days. Did you disassemble and clean it before installing? Did you check the slave dust boot for fluid? Leaks will be contained in the boot. -

CONFIRMED L28 with RB25 Flywheel and 350Z Clutch

NewZed replied to 83turbo280zx's topic in Nissan L6 Forum

Did the cover only rub in one spot, not all three? Seems like you're saying that something was off with the cover. A measurement at the rubbing point might help future people, with reference to Xnke's post about different covers. L series flywheels seem to be getting hard to find in general (the 225 mm is essentially NA from normal sources) so swaps like this will be the only way eventually.. -

Good luck. That picture was from BE-10.

-

Curious, how long is the old bolt compared to new? You could compare while in the slave cylinder, to the new one. I'd guess it's longer and somebody had a short collar problem. I wrote a bunch about checking parts then went back and saw this - "So I just installed a new stock LuK clutch kit in my Z, new slave, master, T.O. bearing and springs, and pivot ball.". Are you sure that pivot ball is correct? That would cause problems if it wasn't. That 0.4 inches of travel though, is still key. If something was bottoming out mechanically, that might stop slave piston travel. But if there's nothing stopping it you need to get it to spec.