All Activity

- Today

-

I got mega burned by Apex on the rear track attack. Was one of the first buyers of it and back then it didn't even have enough parts to even bolt it to the car. The design of the rear kit is just for looks. Much feedback was given to them in how to improve it, but it was widely ignored. Shame because the cradle design is a good base to start off of.

-

On my C&R (Jeirco knockoff) I have a two-piece shifter similar to the original Datsun version or a T-5 shifter where only the handle needs to be removed. The C&R has all the linkage on top, so you have more side clearance, but it is exactly the same three-rod shift fork linkage as the Jerico. Bummer the clutch plate is still catching on the flywheel bolts.

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

a -

Final reference pictures of the rerouted SS -8 and -10 fuel hardline bracketry around the Escort member. I left enough room to run twin -12 but the main choke point is around the massive CD trans. Also for those that asked about the FPG in-tank surge tank bracketry I haven't forgotten have just been busy. The design was finalized along with a custom level sender arrangement and the prototype went for manufacturing a week or two ago so I'll provide more details when I get back to it.

-

A Excellent Video on A Complete Body Restoration of a 240Z car

toolman replied to toolman's topic in Body Kits & Paint

"Oil Can Repair" on Rar Hatch Panel- "Oil Can Repair" on the Rear Hatch Panel is common problem on 240z. The factory tried to solve the problem by adding addition sheet metal around the lock assembly. unfortunately, this(in most cases) was not sufficient to prevent the problem. The problem is aggravated by the push style hatch lock that is utilized. The lock uses a pushing down movement to operate the hatch release. Imagine a 200 plus man forcing his weight on 23 gauge Flat piece of sheet metal opening his hatch. This video shows one method od solving this problem. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Yes I have both. And bleeding the clutch is as simple as opening the bleed screw, let a few drips out, and tighten. The thing that takes longest now is removing that giant shifter and the 3 shift rods. And adjusting shift throws when reinstalling. 3 bolts hold shifter and 2 rod ends per shift rod. I can't find a better way to speed it up. AND I cranked the car Saturday and the clutch is close but still not fully released. So another round is coming. -

Mitchel0407 joined the community

- Yesterday

-

It was the rear main seal leaking, I removed the transmission and could clearly see the oil around the seal:

-

The turbo lamik stuff is very trick, and it has a lot of potential. The weight is a downside, but it's low and centered. I have a buddy who just put one in his 2JZ swapped FC RX-7, and he didn't have to touch the tunnel. There are a couple guys on IG as well who have swapped these in with good success. I think compared to the T56's they are only slightly heavier, but much stronger and have nicer ratios.

-

Transport is booked for next week so this weekend has been misc. final prep. Bunch of random bodywork to minimize filler and some fab/welding, but here's some highlights. I finished clearancing the diff front member for the twin 60mm exhaust. I also clearanced the area around the snout as I will be taking VSS signal for the speedhut speedbox. After some further measurement I'll be vbanding the entire exhaust again as I can gain maybe another 1/4-1/2" ground clearance by reconfiguring the angles over the existing slip joint configuration. As is I think it is similar or better clearance around the diff than the 3" pipe I had tucked there before. Re-fit the AL driveshaft and confirmed my suspicion that the Escort member moved the diff forward ~1/2". Not a big deal but need to remember to re-check the axle plunge depth and shorten the DS if necessary when the time comes. Also marked out where the DS interferes with the factory xmember so will plate in and weld that out later. Finally I've been seeing a lot of very very nicely done s30s in person lately to get an idea of bodywork problem areas and things the owners would have done differently. One area was the rear valence around the exhaust, specifically exhaust was fitted later and required trimming of the rear valence on a finished car. So I went ahead and trimmed out the rear valence accounting for exhaust movement and duplicated the shape on the pass side for symmetry. Worked out a bunch of other fine details as well and at the end of the day it's an imperfect 50 year old car but needing to bash things in or cut things out after a bare metal respray would drive me nuts. It's been a journey but I've met some really cool people and seen some absolutely heavy hitter s30 builds this past few weeks.

-

Pretty cool https://www.seikowatches.com/us-en/products/prospex/special/datsun_limited/

-

Fast Floridian's 240Z Track Build

jhm replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Looking good. Seems like that's always some of the most rewarding parts of any resto....getting all those hard-to-access areas cleaned up, rust repaired, straightened/strengthened/reinforced, and freshly painted. 👍 -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

All painted. Going to do another coat of semigloss for the engine bay, but frame/fenders are ready for suspension 😁 I’m hoping to start next weekend -

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

- Last week

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

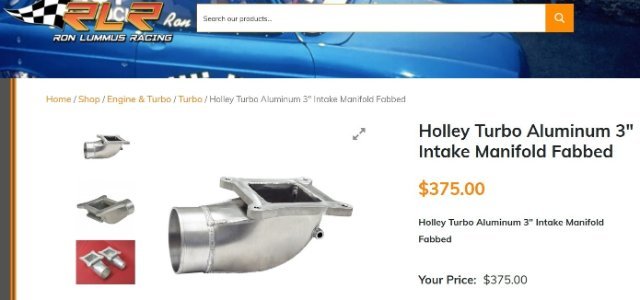

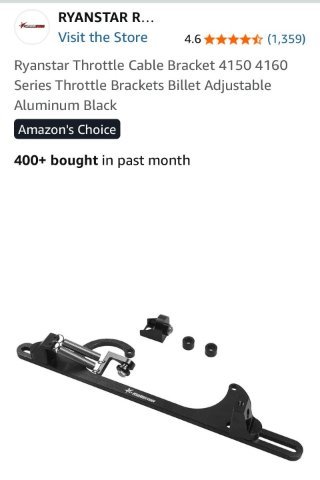

Got more goodies in, front and rear bad dog frame rails and a steering wheel mount for my Holley digital dash. Not sure if I’ll use it, but think it’s a viable option. -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Did final scrapping and cleaning of engine bar and fender area. Dried and going to get first coat of paint on today or tomorrow. -

Skyline_sweden joined the community

-

I think the only downside, other than size, is the 180 pounds these weigh, from my research. DCGs are very heavy and have a deep oil pan that limits ground clearance. For a high HP car where the weight isn't a problem, I think that they could be a good solution. The MaxxECU is a nice bit of kit. I got to see one being put on a friend's car and it had tons of IO for the cost.

-

I'd suggest a flat metal bracket that bolts (rivnuts) to the inner fender and goes over the top of the battery and has a small jog bend to capture the side and then bolts to the upper angle of the drysump tank bracket. And maybe some aluminum angle riveted to the bottom to keep the battery from shifting.

-

On a friend's race car he has two things that help to speed up the removal of the transmission. A dry break on the clutch line and the second is the over the top of the bellhousing exhaust. Having the exhaust out of the way when the car is still warm helps a lot if you need to remove the transmission for gear changes.

-

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

I am posting this to celebrate my triumph! After full assembly of engine and tranny I could not get the clutch to release. Quartermaster 7.25 v-drive attached to L6 flywheel from TTV Racing. Quatermaster 710 series TO bearing. Chevy clutch disks to mate with 4sp Jericho. QM Button clutches require precise gap from fingers to TO bearing of .120-.150 so I removed tranny multiple times and reset the gap with shims. Everytime I measured gap I got a different measurement. The clutch slipped a little with pedal in but required a breaker bar to rotate driveshaft. Remove tranny, reset gap, reinstall, bleed clutch, check release. After maybe 8 times I stopped and thought about it. Then read directions for the 10th time. Suddenly it stuck out, make sure clutch disk does not interfere with flywheel bolts. I've seen this before. Years ago I ran a similar set up with the head ground down on OEM flywheel bolts. This time I am using ARP flywheel bolts for a RB26. They are 12pt bolt heads already kind of thin, so I didnt consider they could interfere. Well I was wrong. So I ground maybe 0.020" off the head and reinstalled. In the pic you can see marks where the clutch rivet went across the bolts and 3 bolts I have already ground down. On the positive side, I am very efficient R&R the tranny now. Maybe 90min total. And it pops into the pilot bearing like a glove. -

Anyone running a Schneider 270-60F-14? Questions about idle

NewZed replied to juggernautjoee's topic in MegaSquirt

https://www.schneidercams.com/270-60F-14_LET6.aspx Did Schneider give you an idea of what vacuum reading you should be able to get? Opening up the lash effectively "detunes" the cam. Less lift. Seems like an odd suggestion. Does your engine have any EGR remnants? The EGR passages have been known to rot inside the manifold and leak internally. -

Well my stock speedo only went to 85mph and i know it was revving a lil high at that point for long distance driving. But hey, if you have 75mph posted signs and your car don't mind 85-90, then u have a good car! I can't imagine an original 84 Maxima wants to do that speed anymore than my zx did when it was stock. Sorry i cant be of any help other than replying to your post, to keep it fresh

-

Building Another Stroker Engine for the Track

clarkspeed replied to inline6's topic in Nissan L6 Forum

Nice work!

-

Who's Online 0 Members, 0 Anonymous, 188 Guests (See full list)

- There are no registered users currently online

.jpg.b34f27553f5960421801c8ab2cbf5db3.thumb.jpg.7889e8073010b6a0d8d6aae0626e768b.jpg)