-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

Pete, your exactly right on both posts! Just got off the phone with Jerry at Schneider and yes valve lash needs to be set since I am taking measurements off of the retainer. Some new numbers with the sprocket in #2 hole; Intake closes 33.5 ABDC Intake opens 3 BTDC Exhaust opens 37 BBDC Exhaust closes 6 BTDC Jerry worked some numbers and felt the intake opening needed to fall inbetween 2-4 degrees opening. I acheived this with the sprocket in # 2 hole. With this setting I am no more than 2 degrees off on any specs. My arm and back are wore out!

-

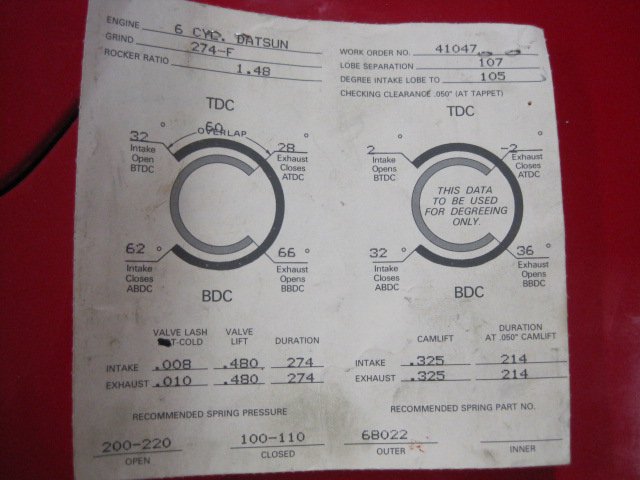

Okay, looking for some guidance here. I am awaiting and hoping Schneider will return my call-but meanwhile here is a pic of my cam card. I have made some assumptions since I haven't confirmed with Schneider yet, but I assume the degreeing numbers on the right are made with zero vlave-lash and at .050. Haven't recieved my Nismo adjustable sprocket yet, so this is using stock sprocket. This is what I cane up with using #1 hole: Intake opens @ 1 degree BTDC Intake closes @ 43 degrees ABDC Exhaust opens @36 BBDC Exhaust closes @4 ATDC Using # 2 hole on sprocket: Intake opens @5 degrees BTDC Intake closes @ 40 degrees ABDC Exhaust opens @40 BBDC Exhaust closes @1 BTDC My concern is that trying to get close to the card for Intake closing is just going to take me further away from the other closing and opening points.

-

Okay, looking for some guidance here. I am awaiting and hoping Schneider will return my call-but meanwhile here is a pic of my cam card. I have made some assumptions since I haven't confirmed with Schneider yet, but I assume the degreeing numbers on the right are made with zero vlave-lash and at .050. Haven't recieved my Nismo adjustable sprocket yet, so this is using stock sprocket. This is what I cane up with using #1 hole: Intake opens @ 1 degree BTDC Intake closes @ 43 degrees ABDC Exhaust opens @36 BBDC Exhaust closes @4 ATDC Using # 2 hole on sprocket: Intake opens @5 degrees BTDC Intake closes @ 40 degrees ABDC Exhaust opens @40 BBDC Exhaust closes @1 BTDC My concern is that trying to get close to the card for Intake closing is just going to take me further away from the other closing and opening points.See next post for attachment

-

Pete, I understand what your saying. This is the whole reason I didn't just throw the cam in and say-well the power is okay, but I better get a bigger one. This is the whole reason I didn't just throw the nearly new Mikunis 40's on my car yet-even though I'v owned them for years,why-because I haven't finished doing the tune on there with my SU's. I am trying to do this the right way and LEARN more than anything. There will be dyno trips involved to. I did my first on the way to ZCON 2010 and found the engine made good power, but was out of tune-and the cam was just thrown in, but now i want to properly dial it in as well as other things and DYNO once again with the SU's----THEN and only THEN the Mikunis go on and then DYNO time. I want to know for sure if I am making progress and learning too, so there will be many trips to the dyno. I appreciate the shared knowledge of all you guys.

-

Just so I'm not misunderstood, I am not looking to advance the cam BEYOND specs. The numbers are coming up retarded, so I want to advance the cam to get to spec. If I could have a choice betwwen the cam slightly retarded or slightly advanced- (because i couldn't get the specs EXACT)- I would rather be slightly advanced. Head is early e-88 with .010 shaved with bigger valves. Flat-tops with no reliefs. I will probably measure piston/valve clearance at some point in all this for future reference to go with a bigger cam. Pete, I will try your method later since this is a symetrical cam profile

-

Thanks Leon.I am confident that I am dead on as far as TDC. I set that up before installing the head. I doubt I am off a tooth, but I will check that out. Bottom end seems really good on little L24, but if she'll give more-I'll take it! The cam is just a 274f grind, so I believe the grind is goaled more for torque then higher rpm power. At this point, I want to get the intake valve closing point on the mark, since this is the most important.

-

Pete, I am attempting to meet the cam card specs, but as I stated earlier, I am not reaching that goal with the stock sprocket setting-at least not #1 position. The readings are coming up retarded, which is the way I ran the engine the last 5k miles.Not looking for any magic, just to see if i notice a power change getting closer to stated specs on card. Schneider tech guy told me at the initial installation that my numbers were coming in slightly retarded, but running a manual gear box would help offset that and i would be losing some bottom end. So that's the way I ran the engine till this point. Now I want to dial it in closer to specs.Also, as I stated in reading Racer Browns article, it seems that you already get a retarding penalty from running a chain driven cam, so I don't want to leave the valve timing retarded. Though I must say the engine ran very good at lower rpms-lots of torque, so it will be interesting to see if feel any difference. As far as valve clearance, I am ASSuming that my meager 480 lift cam should have ample clearance if I am close to specs on the valve timing. As far as head gasket goes, the one I took off measures around 1.2mm and that is what the Nismo measures at once compressed(if I ever get it). since writing the last post I have searched and found how to change the sprocket setting-thanks Leon. When you stated off by a tooth-do you mean too many links between the cam and crank?

-

In the last few days I had my head checked and it's flat, so time to do some degreeing. I set everything up verifying TDC before putting the head on(dial indicator directly on block measuring #1). As before the numbers on my Cam card are not coming up on the degree wheel. I set things at zero lash and measured the intake side and the timing is coming up retarded(atleast 4 degrees). The biggest concern is that the closing point is late-which I would like to rememdy and if anything be earlier then the card states. I found a Nismo adjustable sprocket on line for less than 100$-so I jumped on it. Meanwhile, I thought I would adjust the timing with the stock sprocket since it does allow for advancement-or does it? I realized at this point in time that I was stumped on how to relocate the position of the sprocket to the #2 hole. I did this about 4 years ago when i first put the motor together, but I'm not sure now. So at TDC do I remove the sprocket with chain intact to maintain my 41 link separation from the crank sprocket-then rotate the cam advanced to line up the dowel pin to #2??? Since the factory sprocket has this adjustment to allow for chain stretch-what if the chain has no stretch since it is new-can you still make the adjustment? I reread this thread a couple of times and didn't read where it was spelled out on how this change was done. It might be beneficial to all that reference this thread to know the mechanics of actually changing the timing at the sprocket.

-

Advanced timing is a great if your motor can take it . If it runs better and doesn't detonate- go for it. You should listen for detonation during times that your vacuum advance is involved in your overall timing. I run 20 initial. How much mechanical advance are you running? What's your total timing? If you can't answer these questions then it's time to search!

-

I have been contemplating a high compression turbo build myself with my p-30, but I would seriously consider switching to e-85 if I did this. It's plentiful here in Indiana and less chance of tearing up the motor

-

Found this surfing the net and thought I'd pass it along-I ordered one myself. The best price I've seen for this item. http://www.nissanraceshop.com/product_info.php?products_id=332630

-

I wish they let me keep the damaged one, but no dice. It was curled up on the end-maybe salvagable, but I wasn't taking the risk. Funny thing is(not really funny) I ordered a exhaust gasket from autozone and the same thing happened, looks like they dropped before they put it in the box. Luckily I opened the box right in front of them-no questions asked!

-

Waited 4 weeks for my Nismo gasket and it comes DAMAGED ;( Some idiot at Courtesy Nissan puts a 2 ft long flat gasket in a 3 ft long triangle box with ONE piece of paper for packing. Now I guess I will wait another 4 weeks . Good news is that my machinist said the head is flat, I guess the gasket just have out

-

Getting ready to degree my cam again-since I have the head off right now for a HG issue. I was staring at my cam card yesterday and realized that the numbers were just numbers too me, no real understanding of what the cam designer was looking to do.. I been reading this lately-- http://www.datsport.com/racer-brown.html---- to try an educate myself on cams and engine building. I have a 270f cam from schneider and after doing some reading I was curious as to what changes were made by Schneider to modify the stock carbed cam. From reading this racer Brown article it seems that the stock cams used an arbitrary valve lift number of .020 for degreeing points. My cam card is at the more standard .050 number, so there is no way to make a direct comparison. I was wondering if any of you engine builders have translated the stock cam number using the .050 lift numbers? This way I could compare what Schneider did with their modifications. I was hoping that someone could go put up a cam card and explain the contents of the cam card. Another thing i got from reading this article was that one focused on getting the closing of the intake valve correct as the number 1 priority. It was stated in the article that the slack in the timing chain causes a retarding of the timing. So if I could only get close to the numbers on the card with my non-adjustable cam sprocket-it would be better to favor an advanced timing since the chain will only cause the timing to retard. Any suggestions on measuring piston to valve clearance?

-

Found this searching the Subby sites, they are specifying the oil for clutch type. The subby stuff is the green gear oil. I read on many posts that the guys won't deviate from the OEM oil Thank you for your patience. I researched this in our Technical Service Manuals. No, the LSD gear oil used in your 2006 WRX STI is not used in the 2007 WRX STI. In the Technical Service Manual for your 2006 WRX STI Sedan, it states: Mechanical LSD oil MUST be used for STI model. Recommended oil - Gear oil LSD (Subaru part # K0305Y0900), GL-5 (90) or equivalent. In the Technical Service Manual for the 2007 WRX STI Sedan, it states: Recommended gear oil: GL-5 (75W-90) or equivalent.

-

I've never had to service a LSD diff so i am not familiar with the additives you speak of Jon. I guess these will be available at the parts store. So an additive is necessary regardless what type of LSD you use(torsion, clutch,etc..)?? And the viscosity of oil?

-

Well I went to the auto parts store to get some gear oil for my newly aquired 2005 STI diff. They had no listing or info on what oil was recommended for this type diff. So off to Google land I went and found many answers. It seems though that the clutch type uses a very specific oil to work properly. I noticed what came out of my diff was green in color, so I presume that is the stock stuff from subaru. I finally found a part# k0305y0900 for the subby fluid and I guess the diff just takes one quart. Like to here what you guys have found concerning this.

-

4.5 years later, My Porsche is going to a new home...

madkaw replied to Mikelly's topic in Non Tech Board

Mike, I am jealous of the fact that you have owned such a super car as the Porsche 911. I have considered and still consider giving up the Z and buying a "super car" while I am young enough to enjoy it.Lately I have had a herniated disc issues which is taking the fun out of working on my Z and it will take more work than my back can handle to even come close to a super car with a Z. It seems that a used porsche 911 turbo might be the best bang for buck as far as buying a used super car. For myself, the early Z is hard to top as far as looks(modified with wheels, etc...), but I really do like the 911. I have never driven a car of this caliper, so I can only speculate the experience. I have driven a 95-911n/a and it was very sweet. If a person was willing to spend 50-60K, wouldn't you say the 911 would be the wisest choice for a super car experience and still have a daily driver? Maybe I can get lucky and keep both cars, but as a family man that's not rich, I think it might be asking too much. Also like your choice on a bike-also my choice when I can get one. -

Since your building a N/A motor you should try and go back to that Maxima and see if has the MN47 head on it. That on your L24 block would make a killer street machine. Go to the FAQ's on this site and read BRAAP's thread on heads. Would have loved to see that blow-thru setup running!

-

Like the title reads, I need the studs that fit into the diff cover. They are smaller than the r200 and that's all I have. Willing to trade or pay by money order for some decent ones. Contact me by e-mail stephen_finnerty@yahoo.com

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

madkaw replied to zredbaron's topic in Nissan L6 Forum

Need a little better sound production of that sick motor- freaking race car you got there! -

Nissan sells a head gasket for the 240 that is 1.2 thick- pricey 150$

-

I'm going to stick with my high dollar fancy smancy Nismo Super composite - better then titanium gasket for the 240-260 for 163$ with shipping- the wife will be estatic!

-

I actually plugged in the number today and they were 40$!!! I wish I knew if I could use them on my p-30 block. The description on the gasket I ordered does specify that it is a Nismo high performance composite type head gasket---FANCY! the 40$ gasket has no such description