-

Posts

663 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by gvincent

-

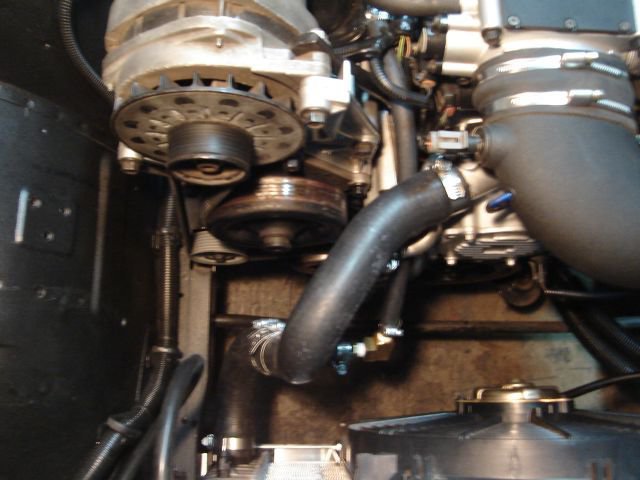

I just had a plate welded up and scrounged a male and a female idler pulley.

I located the male (grooved) pulley about where the AC was on the F body and the Female pulley a little lower than where the power steering pump used to be.

This is all on an F body accessory bracket. If you are using a B body I think it is different but there is a friend the next town over that is starting his LT1 from a Caprice and he says he can use the AC delete pulley hr has and I think he has a setup to delete the PS pump as well, I can check with him for you. I think he is away this weekend though. I can send you pics of my set-up if you like. I am only running 1 tensioner pulley on my set-up, just give me your email, actually I just left you my email on your hose thread.

Thanks,

Greg

-

Hey Greg. Do you have any info on the serpentine belts and pullys for a LT1? I am looking at my set up and I think I am missing something, I have an installed a/c delete and a tensioner pully. The PS was removed and there is no replacement pully yet. I have another tensioner pully in a box brand new, What do I need? Thanks

Larry