-

Posts

1384 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by rossman

-

Did any of you guys end up tuning with the DIY knock detector? I'm interested to hear how well it works. I went with the J&S Interceptor unit. It has a built-in audio out jack. It would be interesting to compare the two.

-

That's just a regular Z/ZX non-turbo gearbox. ATF or the torque you are putting thru it killed it. Replace it with a z32 gearbox and you should be good...assuming you use the correct gear oil .

-

RT Diff Mount - Necessary to notch lower diff mount?

rossman replied to The Woj's topic in Drivetrain

Is it me or does the RT mount bolts on dsommer's 240 look higher than on Woj's 280? If it's true then that could be the difference. -

RT Diff Mount - Necessary to notch lower diff mount?

rossman replied to The Woj's topic in Drivetrain

I'd check to be sure your transmission and differential are lined up prior to cutting on the cross member. -

I ended up buying from Allen's Fasteners. They have the same head markings as pictured above at a considerably lower price. Belmetric's low price had minimum quantities larger than what I needed (including spares).

-

I don't have any caps but I was wondering why you would remove the rear front cross member. Are you replacing it with something else? The cross member is there for a reason other than just supporting the front of the differential. If you remove it and just replace it with caps then you don't have a good load path from one side to the other. Just remove the rubber mount and leave the cross member.

-

Thanks for the compliments! It's about for another status . The front cross member, engine brackets, and a few other drive train brackets went out for powder coating this past Friday. They should be done late next week. Once the front cross member is back in, I plan to install all the suspension components, brakes and wheels. When that is complete I can roll the car out of the garage, pull the engine and route the the stainless fuel lines. I installed the LD28 water pump. Had to shave a little off the front cover to clear the larger impeller. Hopefully it will help control detonation. Also plan to go straight Evans NPGR.

-

The Chronicles of Zarnia:Webisode 1

rossman replied to Two80z4me's topic in S30 Series - 240z, 260z, 280z

"Find one in every car. You'll see." -

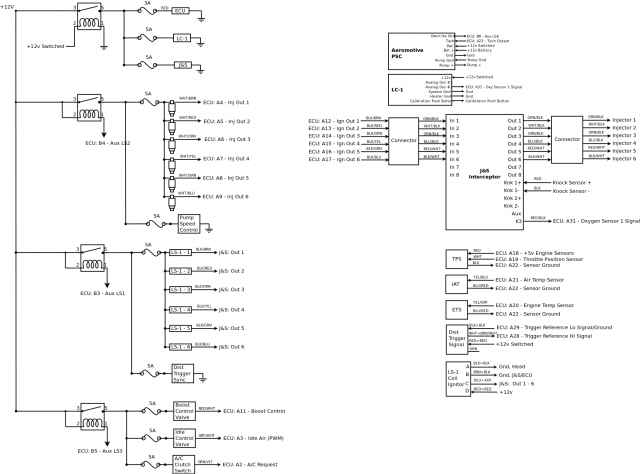

I completely redrew the wiring schematic to include all the components and their connectivity to each other. I'm not sure of the fuse rating for most of the components. Any insight/comments are appreciated.

-

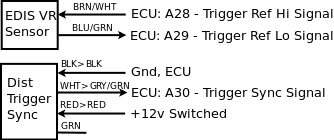

No worries. There are other reasons why I chose to simplify that I didn't state in the thread. The crank sensor mount sticks out and interferes with stock fan, requiring the fan to be offset to clear it. Offsetting the fan forward places it too close to the radiator for comfort. Now I don't have to worry about any of those issues.

-

Ron, you make a strong case for ditching the crank sensor. I think I'm going to go with your (and KTM's) advice. Maybe I'll hold on to the crank sensor hardware in case I decide to try it. Thanks for all the feedback.

-

I hear ya about cheap fasteners. Problem is, I think the fasteners most suppliers are selling cheap, i.e. low quality fasteners. How can I tell the difference? I hadn't actually thought of getting them from Nissan. I'll give Courtesy Nissan a call in the morning.

-

Yeah, McMaster doesn't have them. That is the first place I looked. Allen's Fasteners has them at good prices but I worry about sending money to random websites.

-

I'm looking to replace most of the suspension and drive train fasteners on my S30. The majority of them are M10 x 1.25. That thread combined with zinc plating and class 10.9 seems to be fairly hard to find. The Ace near my house has them but not in the quantities that I need and they are a little expensive at $1.50+ per bolt. Plus, people tend to mix up the bolts so you're never sure what you're getting. Anyway, I'm looking for a good online source for these type bolts. Anybody ever order from Allens Fasteners? Prices look good at less than half Ace's.

-

Yeah I've been getting the same story . I bugged him enough early on that he went ahead and sold me the brackets with the extra lugs for the hand brake calipers. Once he completes the custom cables I'll order the rest of the kit.

-

The main reason I am pursuing it is because, as you guys know, a crank trigger is a more accurate than a distributor since it shortcuts the slop in the distributor's mechanism. Now, whether it is worth pursuing is questionable.

-

Yeah, I'm pretty sure I understand the relationship between the crank and cam although it may not be apparent in my post. I was thinking (probably incorrectly) that Wolf could use the two closely spaced slots (0 and drilled hole, you call them "dual pulse" in the sticky) as an indicator of the crank cycle. The coil firing would be triggered by the crank sensor and the optical sensor in the distributor would be used to indicate the crank position relative to the engine cycle. Not sure how to state that in Wolf terms. As an alternative, I could take your suggestion and cover all but one slot on the disk. A bonded-on thin sheet of stainless sheet might work nicely. By "thin" I mean something like this .003" thick shim material: http://www.mcmaster.com/#shim-stock/=agrfwb. Cheers, Ross

-

The numbers are seemingly small but 2 ft-lbs is 25% more torque. To give you an idea of the force on the bolt, the rough calculation I use for bolt preload is Fp = T/(kD). Assuming D = .315 (M8?) and k = .15 for lubricated threads... Fp = 24/(.15*.315) = 500 lbs of additional preload from ONLY 2 ft-lbs of additional torque. So now you have an additional 500 lbs of force trying to pull out of those aluminum threads.

-

+12v is the plan. I'll research the VR sensor to determine its polarity. I assumed (without actually looking at the software) that it could be set up similar to your "Sequencing Batch Fired Coils" sticky: "Ignition 1 Pulse Offset" is set up to fire relative to slot "0" and "Ignition 1 Pulse Skip" = 5. Every time slot 0 comes around Wolf would know cylinder 1 is on compression TDC. Can Wolf determine the sync pulse in this manner?

-

I'm trying to figure out how wire my Ford VR sensor and ZXT distributor to Wolf to allow sequential ignition firing. Below is my first guess based off KTM's guide in this forum...but his is using only the distributor for the reference signal. Did I guess right? Thanks in advance for your help.

-

You might also want to consider using these all-metal self locking nuts. They are reduced diameter so you can use a smaller socket making access easier.

-

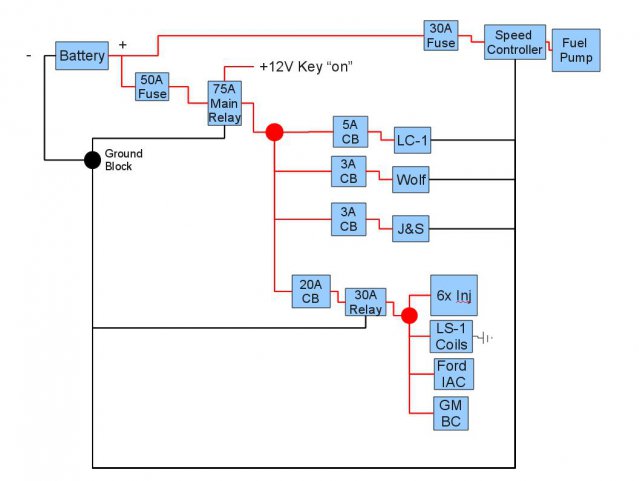

Thanks for your comments Pete. I'm curious why you say not to bother with CB's. Is it cost or just because they are a PITA to deal with? I don't recall seeing any fuses integrated into the Wolf wiring harness. I'll check this evening. Will do Roger that. That is two votes against the big relay. Plan to use the stock fan. Seems logical but the IGN will go on a separate circuit to avoid the problem ktm had. I believe this is a problem specific to Wolf V500. Thanks! That helps a lot! Nice, professional looking drawing.

-

Thanks for your comments ktm. The plan is to use these circuit breakers from Sky Geek. Interesting. I didn't realize that high current relays were unreliable. It makes sense to me to have a main relay to turn on the whole system at one time...but I'm not married to the idea. So, with your scheme, the ignition switch would energize Wolf, J&S and LC-1 then Wolf would energize the fuel pump, coils and ancillary components? The PSC (pump speed controller) has a relay built in to it. Wolf will activate the pump via the PSC as you describe. Will do. I remember reading about that problem now that you mention it. Earlier you stated "I would use a series of relays. One for Wolf, J&S and the LC-1..." I assume J&S can share the same circuit too?

-

I figured I'd throw my power supply schematic up on here for some comments and suggestions. This is the first time I've done something like this so if it's f'ed up, please be easy on me The circuit is based on RTz's power and ground distribution circuit. The biggest unknown for me are the current draws of the injectors, coils, idle air control and boost controller valve. Furthermore, I'm not even sure if the idle air and boost control valve should be part of this circuit. Does this circuit look reasonable? Helpful suggestions welcome!

-

Make sure it's a non-hydraulic lifter head else your asking for trouble. Most, but not all P90A heads have hydraulic lifters.