-

Posts

1384 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by rossman

-

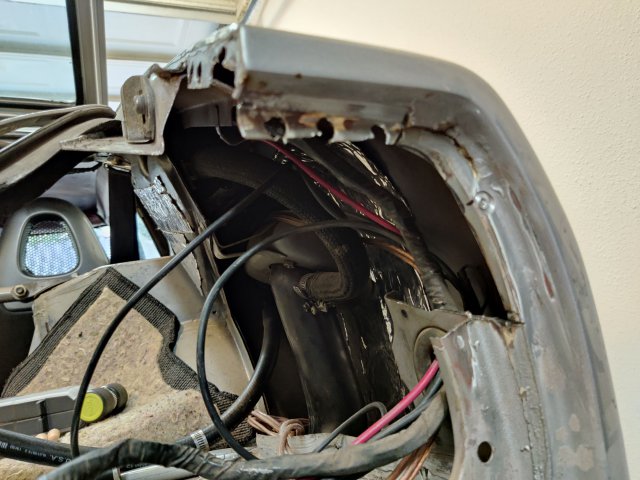

Here are more pictures from today's work. Fortunately the left side is less rotted that right. I was relived to see solid metal under a light surface rust on the underside of the hatch top panel. I'm going to stop there and weld it up. below are my plans for the exposed metal and rust that I cannot reach. 1) All exposed exposed metal will be primed with with PPG two part epoxy primer. 2) Lightly rusted/pitted metal that is hidden will get treated with Rust-oleum Rust Reformer followed by the same epoxy primer. 3) All metal free from the car will get the rust removed by electrolysis then painted with epoxy primer. 4) Overlapping joints will get weld-thru primer followed by seam sealer and cavity wax - I'm doing my best to avoid lap joints. I'm open to suggestions but this is my plan for now. I looked online for long-term testing of rust converters. There are lots of people saying that this or that converter "works great" but no real tested evidence. From what I found, it seems that the Rust-oleum product is pretty decent. I'm not sure how well the epoxy primer will adhere to it...open to suggestions. This is the right side corner prior to cutting it up. I'm fairly certain this area has never been opened up. As you can see there is very little or no effective rust protection in there from the factory. This patch panel if from a sacrificial ass of a 280z. As you can see it's in pretty good shape. I'm glad I had the forsight to grab it when I had the chance. The $150 I paid for it saved me hundreds of hours of metal forming. This is the same area after removing the badly rusted parts. All of the panels have some amount of rust - mostly just surface rust. \ Fortunately the left side is not as bad. I was surprised to see solid metal under the. Oh and the cheap Amazon WEN finger belt sander has paid for itself several times over. It's my new favorite tool for paint/rust removal. The 3M Zirconia belts have lasted at least 5 times longer than the cheapies that came with the tool. They are certainly worth the extra $. There is at least 5 pieces of lap jointed metal coming together here. Prime real-estate for rust. Another valuable tool but a little too pricey though. I have found good alternatives at Home Depot for less. The quick loading system is just their way of locking you into their disks - totally unnecessary, might save a few minutes/day in a production shop. t Here is a good picture of the underside of the 280z top plate. It also has rust problems albeit not as bad, but completely hidden from view. Rust never sleeps!

-

I couldn't have said it better myself! You can see the brown pieces from a brown 280z in one of the pictures showing the hatch. Those pieces are relatively rust free but not 100%. There is much more effective thick, green primer on them. I truly believe there is no such thing as a rust free Datsun or any car from the 70's or earlier. All you have to do to prove it is to peel back the onion.

-

It's been over a year since I posted last and about time for an update. I knocked off all the items on the above "short list" except for the catch can. I purchased a Mishimoto can but haven't installed it yet. I've been driving the car on-and off, going to local car meets - basically having fun with it. This was until earlier this week when I decided to fix some rust around the hatch that has been bugging me since I got the car. In hindsight I should have addressed the rust first...but here we are now, going backwards :). Anyway, boy did I open the proverbial can 'o worms! I didn't get any pictures of what it looked like before I started but I could tell that it had some filler with rust coming up. I figured the rust was worse than I could see so I went ahead and purchased a top plate from MSA. It should be here in a few days. In the mean time I've been digging and cutting out rust. It's turned out to be a much bigger job than originally planned. Here is what it looked like after I removed the top layer of paint and filler. At this moment I knew I was in trouble, lol!! The top plate was removed and it, just kept getting worse. Basically there was significant rot everywhere there was overlapping sheet metal. You can see the shoddy patchwork the PO did (or had done) and the complete lack of rust protectant. I thought my welding was bad!!! As you will see soon, Nissan did little to no rust protection from the factory. This is what is left of the top plate. More to come soon........

-

As @Zetsaz is also experiencing, the cost of upgrading the Datsun L6 is quite expensive and the low bang/buck makes most people consider other alternatives. I was lucky enough to get in the game when it was still fairly inexpensive to pull off using old school Nissan parts. Regarding the CD009, I will say that it shifts really well, probably better than the z32 ever did. I'm sure you will be happy with it after the pain in your wallet fades.

-

Yah, I don't think anyone offers the z32 adapters anymore. It's too bad because the gearboxes are still available new, relatively cheap and the adapters are inexpensive to make.

-

For what it's worth, I run a 3.7 with a z32 gearbox. That is the same gearing the stock z32tt ran. It seems ideal for me for mostly city/suburb driving. At 60 mph in 5th gear the engine is quite happy right around 2300 rpm. It's probably just me but 6 speeds have one too many gears but that may be because I'm just getting lazy in my old age, lol! On a side note, I went to Garrett's site to check out their gtx30 compressor maps and compared it the gtx35. They look identical, which seems a bit odd to me so I inquired to see if there is a mistake.

-

My $0.02: 1. Your gearbox is going to be a weak link in the drivetrain soon. You should consider upgrading to a heavier duty gearbox. There used to be an easy swap for the z32 gearbox but I don't think anyone is selling adapters anymore. 2. Forget about getting a "turbo" cam and just get a good street cam with enough lift (.4"+) to improve flow thru the head. Check out Church of the L on Facebook. There is a guy who goes by Bonk (I believe) who, from what I have read, sells good, custom regrinds - just tell him what you want and he will recommend one. 3. Your budget for a new, modern, turbo is too low in my opinion, double it. If I were buying new I would be looking at the 2nd generation GTX35 line of turbos with a .86 A/R turbine. I have a first generation GT3576R with a .63 A/R turbine. Boost is pretty much all in at 3.5K but it falls off too early. A .82 turbine should get me closer to the sweet spot with my current turbo. A newer generation turbo would give me more low and top end and is an all-round more efficient turbo. 4. For IC, the newer cheap intercoolers seem to be good enough for most people. I have a Godspeed intercooler installed now that I believe is too small. It get's heat soaked quickly. To fix that and help simplify the install, I have a a larger, 3" thick Mishimoto unit waiting on me to get off my butt and install.

-

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Protolabs is a great company. I know a lot about them and have talked with their manufacturing engineers about how they can possibly do what they do. Anyway I won't bore you with my engineer nerdiness. As you've seen from my build thread I've dumped a bunch of money into my little Datsun L so I'm kinda vested in it. I fell in love with my first L28 back in the early 80's and have had one almost continuously since then. It sucks that parts for them are getting so expensive and difficult to find but I figure that if I take care of it, it may outlive me :). Also, the reality for me is that the car it's just a weekend cruiser and more power is really just wasted money/effort. It goes faster than I really need it to already. -

I would recommend a standalone ECU regardless of whether you want to tune it yourself or not. There is much more flexibility built-in to modern ECUs and once you learn how to tune it yourself, you can fine tune it yourself as-needed or completely re-map it if you make a major change to the engine (like a different turbo). I have a well-mannered car using an old Wolf V500 (vintage 2006 ish). I got help with the initial tune and setup from the vendor (Ron Tyler) then learned to fine tune it myself. You just have to be patient and make a small change, drive/test, adjust, drive/test, adjust, drive/test...until you are happy. You will need a wideband A/F meter to help you understand what's happening and see the results as you make them. Sometime soon I will be upgrading my system to a shiny new Haltech Elite 750 that I have sitting on the shelf with a new harness.

-

Might as well go ahead and treat the rusted surfaces while you have access.

-

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

In case you guys didn't know, there are a companies that specialize in instant quotes and rapid turn-around of printed parts. We use Protolabs and Xometry for engineering prototypes that either don't fit on one of our work printers or if it's a large quantity that would overwhelm our few printers. We also use them for machined parts - especially Protolabs who can turn around a fairly complex machined part in ~3 days if you are willing to pay roughly double the price. Xometry will work with a drawing or sketch if that's all you have but it will cost more and you have to fully dimension the part - they don't yet have the capability of pulling data from your head...although it would be convenient if they could! 😄 -

Looking good @Sanchez! I did my floor pans with a Miller 140 MIG using .024 wire on the thin stuff. The smaller wire made it easier to prevent blow-thru. Get yourself one of those magnetic backing plates - it will pay for itself many times over. Also, check out Fitzees Fabrications on YouTube. He has some great DIY metal fabrication videos using simple tools.

-

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

The problem I ran into is that there is very little room, especially for the center vents to use anything other than the provided flex hose with tight bends. It will be interesting to see what you come up with - I may plagiarizer if it suits my needs - especially if it means I can get better flow out of the center vents. -

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

You sir are correct! BUT the system does work with the VA hoses, even in Houston heat and humidity in the middle of August. I considered using other hoses but in the end I just went with the VA tried and true hoses and it just works. Could it be better? Probably - but it does keep me cool. Do you have any experience using a VA system with smooth bore hoses that you can share with us? -

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Lookin' good Omar! With my VintageAir setup there is noticeably less flow thru the center vents. It may be the hose bends restricting flow or maybe the center hole in the evaporator outlet just doesn't flow as well. Maybe you can verify? The the center vent hose in my setup has a pretty sharp and long (~120 deg) bend from the center evaporator outlet to the stock center vent fairing which I was able to use as-is. Designing a shorter fairing would have allowed for an easier, less sharp and possibly better flowing path. It will be interesting to see how well your setup performs. -

Could also be a partially plugged fuel filter. Even though you changed it, there could be a bunch of junk in the tank that is slowly getting sucked thru. If this is what's happening then it would get plugged up faster with a low fuel level. Drain the tank to find out for sure, this would also tell you if it's full of water. As NewZed mentioned, a few more details on exactly what is happening may help us hone in on the problem. For example, is the engine still revving to 6000 rpm but has no power, or is it sluggish and won't rev? There are many things could be causing your problem but until you start doing some diagnostics, you're not going to figure it out.

- 8 replies

-

- compression

- camshaft

-

(and 2 more)

Tagged with:

-

I agree with NewZed. Did you verify that 0 degrees on the crank damper/pulley is, in fact at TDC on cylinder 1 compression stroke? The elastomer pulleys on these old engines tend to crack with age and spin or move on the crankshaft. If this has happened, your timing could be by a lot.

- 8 replies

-

- compression

- camshaft

-

(and 2 more)

Tagged with:

-

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

I have a bunch of a/c fittings that I'll sell you cheep. Let me know if you are interested. I might even have bulkhead connections. -

Sure it's possible. Make a custom compressor bracket or a pre-made RB unit and install a Vintage Air unit under the dash.

-

Get the OEM graphite impregnated gasket.

-

It sounds really good! Looking forward to some dyno numbers.

-

A musician's therapist (The $300 Z)

rossman replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

1) U-joints - Safety first, a completely failed one might ruin your day and it will improve the driving experience 2) Vintage Air - Comfort is important and you will love climate control 3) Rear Control Arms - Will save you money in tires I went with T3 4) Strut bars - I love the look of my Cusco front strut bar. On the rear I have a semi-custom unit I picked up years ago on HZ 5) Bumpers & Speaker brackets - Prioritize brackets 1st if your speakers are loose, just sitting in the hatch due to safety concerns -

Interest in Chassis Strengthening Kits

rossman replied to sabiauto's topic in Brakes, Wheels, Suspension and Chassis

Yup, agree with the above posts - select pieces would be good...I already have Baddog frame rails and sub-frame connectors. -

I'd love to have one. Email sent!