-

Posts

2483 -

Joined

-

Last visited

-

Days Won

24

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Leon

-

What's your idle AFR and what's the F# of your idle jet? Both the idle and main circuit affect cruise mixture strength. I've attached Keith Franck's white paper on tuning Webers (SK is essentially the same), it should explain some things about sidedrafts that none of the tuning books nor manuals talk about. Weber_DCOE_Tuning_White_Paper.pdf

-

Yeah, it's in my build thread:

-

You should've absolutely done a valve adjustment by now but that is of course separate from any fuel leakage issues. Which barrels are leaking?

-

Put me down for using the bigger lift cam. Max lift isn't one of many aspects of cam design. Holding duration constant, you will have a more aggressive ramp with the .540" cam, meaning you will achieve higher lift per crank angle. More area under the curve equals more flow due to a decreased flow restriction. Porting also decreases flow restriction and has an additive effect. Not sure what you mean by the flow "saturates". I run the Isky L6 grind (270 duration/.540" lift). I use flat-top pistons, without valve reliefs, and stock retainers along with Isky springs and whatever Chevy valve stem seals Rebello uses.

-

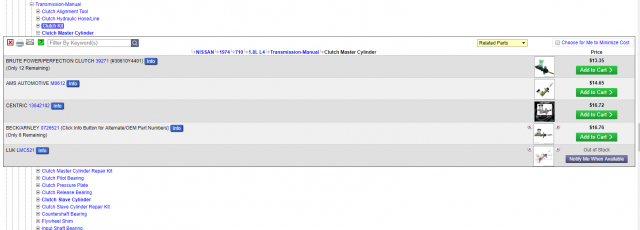

Using the pictures as a guide, looks like either the Centric or AMS are your best bets.

-

Sweet! Glad to see one's of Derek's heads make an appearance in a build thread. That clutch master cylinder is ready to self-clearance the air cleaner as soon as the motor fires up. It may need a little clearance dent, as painful as that may be to do. Looking forward to see this come together!

-

Ah, you never mentioned it was coming from the pump nozzles! Have you verified the state of the check ball and weight, underneath the inspection screws located beneath the float cover?

-

If the needle and seats don't leak, what makes you think it's a fuel pressure issue? Sounds like you ruled that out. Sometimes the needle/seat can get jammed and needs a love tap with the back of a screwdriver. Have you tried to run it since messing with the float covers?

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

Leon replied to zredbaron's topic in Nissan L6 Forum

I'll say it again, find a shop with a Dynapack. No fussing with ignition pickups and they are very consistent. Always be ready for it all to go wrong! -

NA 3.1L=>head & camshaft questions. No shortcuts, max

Leon replied to zredbaron's topic in Nissan L6 Forum

Well it sounded great in that video! Sorry to hear but glad you caught the issues before tossing driveline bits all over the road (or track). I highly recommend finding a shop with a Dynapack in your area, you can thank me later. -

Bushings replaced - Car sitting high

Leon replied to sjuhawks19's topic in Brakes, Wheels, Suspension and Chassis

It's critical that rubber bushings are torqued with the car at ride height. Rubber bushings rely on the rubber between the inner and outer metals to stretch as the suspension moves through its travel. The bushings will see added wear and not work as designed, if you leave them pre-loaded and "let them settle". -

NA 3.1L=>head & camshaft questions. No shortcuts, max

Leon replied to zredbaron's topic in Nissan L6 Forum

Larger chokes will tip in the mains later so your mixture is showing lean due to that. Try tipping in at a higher RPM. You shouldn't have to make an abnormally larger step-up in mains for a 2mm increase in choke size. E-tubes affect both tip-in and the AFR curve when on the mains. The interaction between float level and emulsion tube is critical to both. Run what you got tomorrow and do your best to keep the tests controlled, otherwise it will be impossible to tell the difference between runs. Sounds like you did a pretty good job of preparing. Looking forward to hearing about what you find. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

Leon replied to zredbaron's topic in Nissan L6 Forum

Dynapack is king of chassis dynos as far as I'm concerned. A much more precise machine than any roller. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

Leon replied to zredbaron's topic in Nissan L6 Forum

For a quick and dirty measurement, use an IR gun on your oil pan, radiator, cylinder head, and intake. Otherwise, you're looking at plumbing in oil temp and IAT sensors (assuming you already have a decent water temp gauge). You can also get creative and mount some thermocouples to the important bits but you'd want a datalogger to read them. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

Leon replied to zredbaron's topic in Nissan L6 Forum

The obvious is often missed. 🙂 Glad I can be of some help! If I were closer, I'd attempt to involve myself more. I've done some exploratory dyno sessions like this and always either run out of time, something goes wrong, and/or I question my data because I didn't log engine temps. Doing my best to pass on my experience. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

Leon replied to zredbaron's topic in Nissan L6 Forum

Your quest is noble but as with any good experiment, you may find it difficult to get proper results without controlling key variables. At the very least, closely monitor oil, coolant, and intake temps. Trans, diff, and wheel bearing temps play into it as well and if it's a rolling drum type dyno, keep an eye on your tire pressures. I hope this dyno shop has a good ventilation system, it's no fun being in a hot, fume-filled dyno room all day. Do a dry run beforehand, practice swapping out whatever you'll be swapping out. Time yourself so you have a clearer expectation of what you'll be able to get done. Things always take longer than they do... -

Here's a much simpler method to checking whether it's a float level issue. Take a jet cover off and pull one main stack out. Use a flashlight to look down into the empty hole and see if fuel is spilling over the brim to the auxiliary venturi passageway. If it is, you have a float/needle and seat issue. This can be done with the fuel pump on (if electric) and/or the car running. It should take all of 30 seconds to do.

-

The MJ is crank-triggered thus more accurate. It also uses a coil pack which enables higher RPM coil stability. There is a larger tuning window with MJ as it gives you a 3D map whereas the 123 only let's you program in individual 2D mechanical advance and vacuum advance curves. That's my biggest gripe with the 123, they should just give you a map instead of dumbing down their tech. With that said, the 123 looks the part and I don't have to mount the extra bits that you would with the MJ.

-

I've got one. Love it for the tuneability along with retaining old-school looks. My previous Z had Webers + Megajolt which is objectively a better system but I wanted to keep this one period-looking.

-

That's a C10 Skyline with a GTR airbox. Looks great!

-

Clutch pressure plate? Clutch slave cylinder issue?

Leon replied to tamo3's topic in S30 Series - 240z, 260z, 280z

If you used a stock clutch, the pedal will be lighter than expected as mentioned above. I also agree that you might still have some air in the line. Frankly, I wouldn't worry about it unless you know you have an actual issue. The worst that will happen is you start the car and can't put it in gear because your clutch isn't disengaging. -

Clutch pressure plate? Clutch slave cylinder issue?

Leon replied to tamo3's topic in S30 Series - 240z, 260z, 280z

Looks normal to me, it's a self adjusting slave just doing its job. Have you been able to drive the car yet? -

STP oil treatment with zinc....DON'T use it.

Leon replied to Ken Smith's topic in S30 Series - 240z, 260z, 280z

I used Mobil1 on my previous Z for years without issue... -

Agreed, it's been really fun to see you develop this car as well as run it with NASA. That's what those race classes are all about, pick a chassis and have fun with it instead of "last year's winner drove an M3 so I'm building an M3". I run TT (not in a Z, I'm not brave enough) with NASA but looking to get into W2W, if not this year then 2019. Hoping to also run the 25 Hour next year... Good luck in Chuckwalla!