-

Posts

2483 -

Joined

-

Last visited

-

Days Won

24

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Leon

-

I'm not so sure about that cantilevered rod-end boss. That's a fatigue failure waiting to happen...

-

L28ET Valve float and spring recommendations, aftermarket cam

Leon replied to Zcardude's topic in Nissan L6 Forum

Cam timing looks ok and shouldn't cause the issues you're seeing. The shiny links are used to set timing on chain install, the groove and notch are used for all other checks and adjustments as OP has done. My money is on a calibration or crank sensor issue. -

Why would you ship that from America? A 2+2 story

Leon replied to Villeman's topic in S30 Series - 240z, 260z, 280z

Yup, that's a Traction Avant! Very cool. -

Sectioning is complete! Will sandblast and paint the struts as soon as time allows. Once they're painted, I'll reassemble with fresh bearings and finally install the rear disk brake kit I've had lying around for about 4 years now. Really looking forward to actually having some bump travel! It feels good to be working on the Z again. There are a few more niggling issues to deal with, mainly refining the tune and getting the speedo and tach working reliably.

-

Your oil temps will be hotter on track than autoX or regular driving. Hotter oil is less viscous and easier to pump, thus pressure drops. It's not necessarily a sign that something is wrong but if you're worried, install an oil temp gauge. If you're running synthetic, you should be fine to about 280°F.

-

Great work Ryan! Love the tidy engine bay. Any plans to go to the dyno soon? I know you've been trying to set that up for a while.

-

Dual Ball Joint Strut Modification

Leon replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Setting the geometry up to get what you want at nominal ride height and steer is simple enough but one of the big complications you're not factoring in is that the virtual pivot/kingpin axis moves around during steer, unlike the single arm setup. If you look back at the Pontiac video, this can be visualized really easily and you can see that scrub increases on the inside tire and decreases on the outside during steer, in this case. Also, caster drops on the outside and increases on the inside. The two things you don't want. However, going to a split-lower arm on an S30 would result in a compression link setup instead of tension link, as Pontiac (Holden) has done, so I bet the resulting geometry would be more favorable regarding caster and scrub. Still, a full kinematic sweep is needed (ideally K&C) to be sure you're getting the effects you want. As an aside, TC rod positioning on the control arm does have an effect on geometry, e.g. caster gain (therefore kinematic anti-dive) and bump steer. It can be seem as a sort-of front semi-trailing (leading) arm. This is minutia in the sandbox that we're playing in but worth noting that it does do something.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Bummer. They should've come with a warranty card when you bought them. Contact Tokico and see if they can give you any sort of goodwill.

-

You've lost the gas charge so it's done. Hope it's still under warranty...

-

In my case, they ate the OEM guides in about 1000 miles.

-

I've had similar poor experiences with SI valves, with the caveat that I ran them on OEM guides. When I talked to Dave about it, he mentioned hearing about others with similar issues. Went with OEM exhaust valves and Supertech intakes on his recommendation. Had him work the head on the second go-around...

-

Front Suspension Swap? Anybody done one

Leon replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

You used the b-word... If I may summarize your post, you want to convert the front and rear suspension in your 280Z from struts to dual A-arms because you feel like you'll have "more adjustability" and "the suspension will move around less"? And because your Corvette couldn't keep up with Porsches in slow corners? Then some stuff about roll centers that showed a fundamental lack misunderstanding of what roll centers do. You might as well say, "if your anti-roll bar rates were more equal, it would be a better setup". Roll centers are just one component of anti-roll which itself is just one component of vehicle handling. It's all a system. You will be frustrated and lost if you're only looking at single characteristics in isolation. You have to understand the problem first, ask yourself the right questions, research and execute. In reality, that's an iterative loop. Currently, there is a lack of understanding and lack of clarity as to your wants and therefore needs. I've seen the Apex kit and while nicely crafted, it represents the above statement. -

-

Forgot to mention, I threw the wheels on the tire balancer and they all had borderline-to-excessive road force (14-28lb). That explains the slight vibration in the steering wheel (combined with the excessive play in the steering rack). Unfortunately, looks like the tires have all been flat-spotted from sitting stagnant for a few years when the car sat. There are no issues with driving on them but the slight steering wheel shake is annoying. I'll have to accelerate the wear a bit, I think. I'd like to get some 15X8 Wats as the 16" Panasports are just a bit too big for my tastes but the tire options are unfortunately limited to either some cheap no-seasons or R-comps. Might just go for the 15s and just send it with some R-comps since it's a fair weather car. If anybody's interested in some 16X7 zero-offset, almost brand-new Panasports let me know and it may just send me over the edge... I'll also have to find a good source for Wats.

-

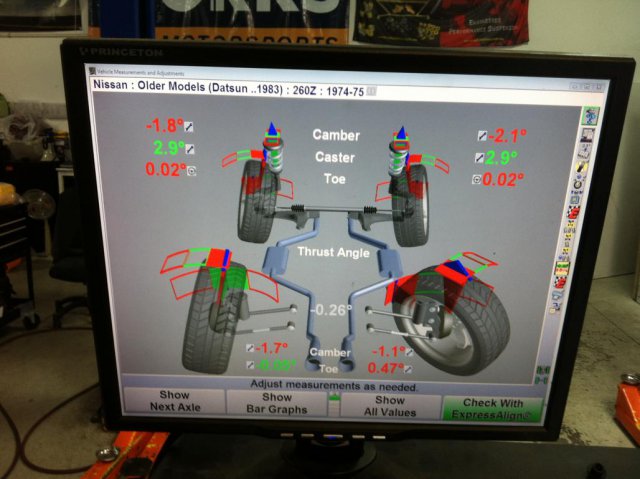

It's been long enough! The car has been on the road for a few years now and I needed to catch up on some maintenance and upgrades this past Friday. On the to-do list was some maintenance, mainly diagnosing a clunky front end, as well as a new speedo cable and the long-awaited LSD and fuel pump install. There were wins and losses on this day! But first, the wins... It's always nice to have friends help out to make things go quicker and today was no different. We got the rear end out without much trouble, it's nice to work on a freshly put-together California car. The LSD is on the left, along with some cruddy old axles I had lying around. Those will be addressed later... While the diff was out, we thought about how to tackle my rear toe issue. The chassis doesn't look like it's ever been hit but something is definitely off. Here are the rear toe numbers from a while back: For the sake of on-car adjustability, we decided to slot the transverse link brace. I calculated, based on rough measurements, that we'd need ~1mm slot so we milled off 2mm. Slotted vs stock And a major win, we're finally at zero thrust angle! Goes to show that it doesn't take much to have the rear toe go out of spec, especially considering a stock Z has no adjustment back there. (The amount of cross-camber is annoying and I plan to find a way to fix that as well) The LSD install went smoothly and we finished up late that night. It's clunkier than my old diff, yet to be determined whether it's the backlash or the u-joints in the axles. There's also a bit more gear whine but not really in cruising RPM ranges. Filled it with Redline GL-5 diff fluid which has friction modifiers in the formulation, the clutches are nice and quiet so far. Acceleration is definitely peppier but it's not quite the 80mph cruiser it used to be. I haven't had a chance to push the LSD much yet but that'll come! Now for the other stuff... After a quick investigation, the clunky front end turned out to be a loose FR gland nut. We snugged up the rest as well. Channel locks did the trick without any drama or disassembly. However, that wasn't the only clunk. Grabbing the wheel at 9 and 3 also revealed a lot of play in the steering. We initially thought it was an inner tie rod but it turns out the play is internal to the steering rack (!). I plan to see whether I can make any adjustments to fix that. If it's too far gone, I have a spare rack I can toss in. If that happens, I'm curious to measure the rack ratios to see if there's a difference considering my spare is a 240Z rack and I have no idea what's in there currently. The speedo cable went in without much fuss but the speedo is still non-functional. Haven't probed further. I did put a matching 19T (white, 3.9 diff) speedo gear into the tranny so the speedo should be accurate once it's actually working. We didn't have time to do anything about the fuel pump so that's been postponed. The major annoyances left with the car is the lack of bump travel causing the suspension to bottom out when it shouldn't and the rev-hang issue. We'll be sectioning a spare set of struts in the coming weeks to deal with the former. Once those are dealt with, the refinement level and enjoyment will go way up.

-

Front Suspension Swap? Anybody done one

Leon replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

No, it's not trolling and is indeed carefully chosen. Read the thread. -

Front Suspension Swap? Anybody done one

Leon replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

Like most discussions on the internet, I'm sure this would've went much better if it were done in person. I'm passionate about taking a data-driven approach to problem solving and it's frustrating when people don't read and process what's been written. Especially when we're having a technical discussion which involves carefully chosen wording and little riff-raff. -

Front Suspension Swap? Anybody done one

Leon replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

You took what you said and what I corroborated and then completely contradicted it in your response to me, seemingly just to start an argument. That's the only way that statement could be taken, no matter what your intentions were. Point taken on the struts but the conclusion to your post was that statement above which certainly seemed like trolling for a pissing match. Anyway... If you're going to graft a double-wishbone suspension onto your Z, more power to you! I enjoy seeing cool fabrication projects. But when the premise involves just tossing something in because it might theoretically be "better", that doesn't fly around here and is the reason HBZ used to be great. This would've been thrown in the Shed long ago... -

Front Suspension Swap? Anybody done one

Leon replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

The irony is tantalizing... People, especially "internet experts", love to fixate on one attribute that they may or may not understand very well and always miss the big picture. I'm sure you can dig up endless amounts of convincing information on the great importance of Ackermann, or camber gain, or front toe settings, or rod/stroke ratio, or backpressure, ad nauseam. What's lacking is looking at the system as a whole. What is the use-case for the car? In this thread, we seem to be talking about a track car. What's your maximum steering input on a road course? Maybe 120 degrees? Even with 100% Ackermann, you're going to see negligible differences between L/R slip angles. To quote an excerpt from page 545 in "The Multibody Systems Approach to Vehicle Dynamics" by Blundell and Harty (my emphasis in bold): It's the same story with caster angle, it's effects are also dependent on steer. Steer angles on the track are low and thus caster effects are minimized. It's a slightly different story at an autocross, depending on how tight the course is, but lack of caster can be mitigated with adjustments to static camber, camber compliance, and roll stiffness. The solution to lack of camber gain is, you guessed it, static camber. The various suspensions that have been put into cars were all invented for a reason. There is no best. I hope I've done my part in resuscitating said dead engineers. -

Front Suspension Swap? Anybody done one

Leon replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

I can see where this is going and I'm not interested in getting sucked into another tedious, head-banging, never-ending straw man argument. In fact, I'll bet the OP never returns or follows through so this is likely to turn into another pissing contest... Sure, there are some modern strut suspensions that use split-lower arms but not all of them do, the E30/E36/E46 M3 for example. I used Ben's statement as a jumping-off point as he decried struts as the sole reason the Z isn't competitive anymore which I don't agree with. It could be (is) a myriad of factors that all add up. It's not a malicious jab but a friendly argument, and he redeemed himself afterwards saying that in spite of the apparently non-competitive struts, his car handles fine, wizard-like even. And this is coming from someone that is actively competing. You're getting things twisted, Jon. I like how you threw in "better geometry" into the argument when what I really said was, "thinking you can just graft a double-wishbone setup into a car and have it be better is a bit silly". Obtaining better geometry is not at all a trivial task, which is precisely what I had meant if you look back at the previous sentence, and most people don't have the knowledge and/or skills to pull it off. Maybe you can agree, considering the last paragraph in your first reply essentially argues the same exact point which you've then gone and contradicted in your reply: I run 225mm rubber on my Z and it's fine. Camber plates give me about -2.5° of camber. I'm not competing with anyone but it's not a bad handling car by any means. Ackerman doesn't matter as much as you think it does and caster/camber gain don't matter much either if you dial in enough static camber. -

Front Suspension Swap? Anybody done one

Leon replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

Camber gain, shmamber gain. Just dial in your static and send it. It'll be fine. I would not place the entire blame of a car being non-competitive on the fact that it has a strut suspension. Are M3s non-competitive? How about Porsche 911s and Caymans? Yeah, they have other crap in the rear but you get the point. OP, what limitations of the strut are you planning on eliminating with your double-wishbone setup? Have you driven the car on track and gone through the process of dialing in the chassis? I'm not saying that the S30 has the most optimal geometry but to think you can just graft a double-wishbone setup into a car and have it be better is a bit silly. Why not just spend the time and money on dialing in what you have? Unless the real reason for the question is that you just want to play around and make something different, in which case as you were... -

Excellent! Curious how they fit.

-

If you plan to make your own, here is a quote from Keith: Use polycarbonate, as acrylic will lose its transparency after enough contact with gasoline.

-

Keith sells all of his stuff here: https://www.webstore.com/user,pgr,82598,owner_id,other_items However, I don't think he makes the optical tool anymore. You can make one yourself using polycarbonate rod stock (I think 1/4" should work but measure your e-tube well to be sure) and a plastic sleeve. Alternatively, I've also used the depth gauge of a caliper.

-

Interesting, I'm not familiar with that naming convention. If we assume that the 50 is the fuel orifice and 100 is air, I'm surprised at how soggy your cruise is. How many progressive holes do these carbs have? Do you have pin gauges or some way of measuring small orifices? Drill bits could be a good substitute, double-check with a caliper. See if you can measure the hole diameter in the idle jet (part with 50/100 engraved in it) as well as your progression holes. Also measure your float level using Keith's method and let us know what you get.