-

Posts

250 -

Joined

-

Last visited

-

Days Won

18

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Invincibleextremes

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Most likely mig, it'll be steel, 1/2 inch on some parts, 1 inch on others, then all drilled using a jig and then welded together using another jig. The bolt on hub will add strength as well. I have no idea on what you'll be using for a bolt on hub, since the explorers use a press in bearing, but I would gladly sell you a pair of knuckles that you can drill for your own hub of choice or just use 2015 mustang hubs like I am. Also, the drive line shop has 930 axles for both the explorer 31 spline and the 2015 mustang 34 spline, so getting axles to use 2015 mustang hubs and the explorer diff is an off the shelf combo that they will gladly sell you.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Already designed it, just need to build a mockup, check all the shapes in real life, and then get the pieces laser cut, welded together etc.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Yeah I was really tempted to do a complete subframe, but the 64 inch track width didn't appeal to me, plus it would only solve the issue of a monster diff in my car, not the masses... And because I have a youtube channel, and there's a MASSIVE hole in the market for affordable differential solutions and coilover and disc brakes I figured bringing some to market was a no brainer. Btw, if you could give me the outer dimensions of the front diff mount bushings I would be greatful. I don't have any on hand but I plan in using them in a different location to isolate the diff. The factory 4 holes are all going to be hard mount, and the bushings will be on the mustache bar and on the very front. I'm detaching the very front bit from the rest of the cradle, and using bushings between the two parts.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Thanks. Yeah my ideas will be public and in place in a few days. That's awesome you're building A arms and such, I toyed with the idea of using the entire setup, but there's just too many moving pieces... so I'm sticking to datsun geometry. It may even come to pass that your A arms and my cradles will be the go to for guys with high hp... or it may not, as it's highly unlikely you're going to use the factory r200 mount points... either way, it's a win win for everyone. The points you bring up about the super 8.8 is exactly what I've been saying about it. They are hands down better than anything else out there for the money. My reasoning for the 2014 brakes and the 1995 brakes are because im using 2014 fronts and the 1995 is a great option for guys wanting 15 inch rear slicks... so it's a win win. And yeah, I'm going for knuckles, because of the neon coilovers, and because there's a lot already available in terms of custom control arms and r200 mustache bars.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

I also stated in a later post why I will not be using the explorer 8.8, I'd be more than happy to build you a mount, but it's not something I will be producing full time.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

I doubt they're going to harden them. Really depends on the shop. And as far as welding the axles, I wouldn't do that. Once I start making serious power in this car I plan on buying 2,000 hp axles. They're only 1,400 so it's well worth it.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

There's a thread in the drivetrain forum about the diff swap. You can also follow my work on my youtube channel or it's Facebook page. Www.youtube.com/invincibleextremes

- 91 replies

-

- suspension

- 240z

- (and 5 more)

-

Working on the rear at the same time, I should have it all together in a few days and have more pictures. The ball joint is the stub cut off the 2014 mustang lower, and I trace it and cut off the pocket for the factory datsun ball joint location. Then locate the mustang stub on the control arm and weld away. Next to impossible to mess up... there's nowhere for it to be besides exactly where you cut out for it, because you traced it in the first place...

- 91 replies

-

- suspension

- 240z

- (and 5 more)

-

Splicing in a 2014 mustang ball joint pocket was a piece of cake. It all came together no problems. Using the factory srt4 bottom strut hole and placing the top of the mustang spindle against the strut when drilling the upper hole sets it up with the perfect camber at ride height. Just a touch negative. My only concern is the strut and ball joint are no longer in line with each other. It's close, but the strut is inboard by 1 inch on this setup. I'll be paying close attention to it to see if this affects the shock any. It's not as drastic as the factory rear suspension. But I'll still be looking into what can possibly be done about this...

- 91 replies

-

- suspension

- 240z

- (and 5 more)

-

240Z 5 Lug Front/Rear Conversion

Invincibleextremes replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

100% right, it's just money. At this point, some 5 lug stubs, drill the drums and be on your way enjoying your ride. That's really the most important thing, enjoying the cars you build. -

240Z 5 Lug Front/Rear Conversion

Invincibleextremes replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

Gotcha, personally I would never have made that choice, but that's me, I'm not a fan of current datsun parts pricing. -

240Z 5 Lug Front/Rear Conversion

Invincibleextremes replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

My advice? Sell the bc coilovers, and do what I did for the front, then use my rear knuckles with bolt on 240sx 5 lug hubs and 240sx cv axles, that way you get cheap 5 lug setup and also cheap cv axles that work with your r200.... The cv axles alone will eat you alive in costs, you know that. -

240Z 5 Lug Front/Rear Conversion

Invincibleextremes replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

Have you been following what I'm Doing? I have 5 lug front and rear, and a monster diff and badass axles and monster 4 wheel disc brakes and it cost me around 2k to do on my 240z... -

Almost done setting up the front with 13.2 inch brakes and 17x9.5 wheels with 4 inch backspace. Going to use techno toy tuning 5/8 tie rod ends. And still need to clean up the caliper where it touches the wheels (wouldnt be an issue if i ised 12.4 inch brakes) and fab up the 2014 mustang ball joint to the control arm. Using the 240z isolator was easy, worked out pretty good.

- 91 replies

-

- suspension

- 240z

- (and 5 more)

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Just took apart the 2015 axles to send them out and get them cut and splined for 75 each. It's costing me a total of 300 or less for the pair of axles for this swap.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Yeah I've concluded that I'll only be making the bushing version, and that those who want a hardmount can simply buy aluminum bushings... Which should be a win win for everyone. I'm back in Portland today and will spend the next few days bolting up everything in my car and cutting and welding as needed to see the final prototype. Yeah I've seen your posts on insta, it's one cool ride. Currently barely have 300 or some odd horsepower but I do plan on going FULL retard with it in the future- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

My main takeaway from watching everyone else try building these kits if the pricing of support parts... a cheap 8.8 does you no good without cheap brakes... And cheap struts etc... Also, I worked very hard to design my setup as a one piece cradle for the hardmount version, and a 3/4 cradle for the bushing mounted one. I believe that the current offering from others on the market put too much stress on 4 small welded nuts on the factory r200 mount... especially when they hang an arm out to give it even more destructive leverage and put a flexible bushing on there... bad engineering at its finest. The isolated version will basically be what you see there, but have the bushings located above and in between the 4 bolts... seeing only vertical stresses, no twisting force. Also of note, in both the isolated and the hard mount version, the bottom plate is tied in to the control arm crossmember. And if the end user wants, the whole cradle can be welded to it, making the hardmount setup extremely strong. Oh, and it all fits with the factory verticals and the r200 mustache bar... meaning you can use a stock one or a fancy aluminum one.... whatever you please. Also means that it should work with sway bars, provided the axles themselves aren't too big in diameter... that I'm not sure of yet. These are very important things that I spent serious time working around. Can't beat 12 dollar rotors and 30 dollar calipers and the ability to run 15 inch wheels for slicks, if that's your need. Or run 2014 mustang brakes and rock a bad to the bone street beast.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

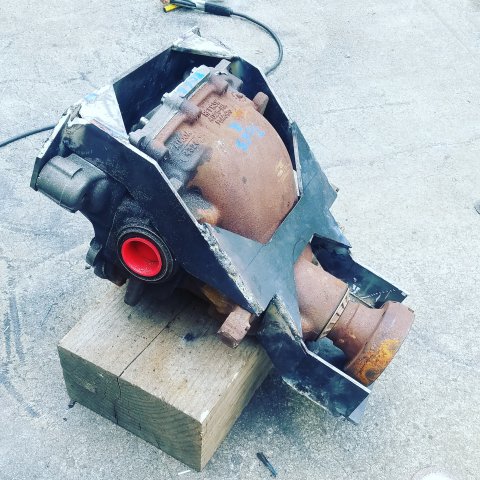

The ugly proof of concept prototype fits like a glove, both on the car, and on the diff itself. So far so good. Obviously still missing the front diff mounts and some other improvements, but the beta version is almost ready to go into my datsun. Its 2 inches shorter than an r200 to boot, so I'll move my engine back some... And no, the final product won't be hacked together with a flux core welder.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Thanks, it was only last night when I realized I can actually have something useful for the r200 crowd, and not just the super 8.8 swap guys.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Got the rear suspension knuckles designed. I was actually able to design it to work with the 2015 bolt on mustang hubs, and work with both the 1995 and 2014 mustang brakes. This allows you to use 1995 mustang brakes and use 15 inch wheels with slicks. Also, had no problem designing it to work with 240sx s13 bolt on hubs as well, meaning people will be able to buy just the knuckles, and use 240sx bolt on hubs, and disc brakes and stay 4 lug and just use custom length 240sx axles and cheap 2004 srt4 coilovers. The Longnose r200 and shortnose r200 have an interchangeable to some degree carrier which means 240sx cv axles should work if they are shortened. Win win in my book. This setup can be used completely to support high hp or just piecemeal to get rid of the stub axle and companion flange get up and be able to use a much better priced coilover option. Still working on designing the mount for the super 8.8 itself. I'll keep everyone posted.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

I have 300zxt axles in my 240z and they fit with the same adapter companion flange deal. I'll be ditching the whole thing soon though. I'm swapping to a 2015 mustang diff and hubs.

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

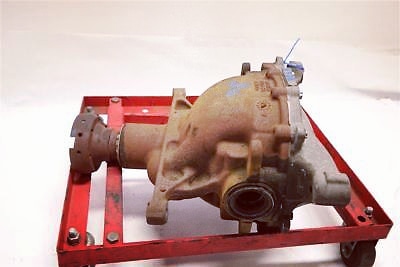

Got the diff. It was 350 bucks. 3.31 gearing and limited slip. Now that the last piece of the puzzle is here, and I bought the wheels, it's time to start tearing apart my 240z and welding together a working mount for this.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

I bought 2014 mustang lower control arms for 50 bucks each, and I'm going to splice the tip with the 240z control arm, making a hybrid arm. I can't afford the wheels or I would have all this built already. Actually... ordering the wheels today, so hope to have it hacked together soon.

- 91 replies

-

- suspension

- 240z

- (and 5 more)

-

Yeah, the fronts. I'm not really following you. I can't imagine there being any hub deflection if that's what you're saying may happen. These parts are designed for a car over a thousand pounds heavier.

- 91 replies

-

- suspension

- 240z

- (and 5 more)

-

As in the rear stub axles? The setup I'm designing doesn't use stub axles, but rather bolt on hubs like the newer Nissan stuff. I think that's what the other guy was saying when he was talking about large bore hollow axles too.

- 91 replies

-

- suspension

- 240z

- (and 5 more)