tube80z

Super Moderators-

Posts

1401 -

Joined

-

Last visited

-

Days Won

31

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by tube80z

-

I'll take a moment to reply to the tone of this comment. On HybridZ we (admins) are not suppressing feedback about vendors. What we are doing is trying to make sure a thread stays on topic so that future users will be able to use search and find good quality content that is helpful and relevant to their search. Ideally the original thread should have stayed on topic and a new thread started about vendor feedback. A link could be left in the technical thread and both discussions could happen and be more likely to be found be search in the future. Hope that helps, Cary

-

I have locked this topic as it has strayed far from the original post. I will leave this up and if there are relevant replies that address the actual topic I will approve. I think there is enough good information to leave it rather than sending it to the shed.

-

Plates around bell-housing - racing application

tube80z replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

I guess one question is how low RPM do you plan to drive? When racing I'd think most of the time you'd be above 2500-3500 on the low end and a light flywheel will be helpful. -

Plates around bell-housing - racing application

tube80z replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

I used to street drive a 10 pound flywheel with no problems. I personally think it has a lot to do with you set the bite point where the clutch hooks up and this can vary widely between pressure plates. That requires some fiddling between master and slave cylinder pushrod lengths. This isn't so much a problem for the inline 6 because they make decent torque off the line. It also depends on clutch disc material and if it has a sprung clutch hub. -

They do. But I've seen this interpreted different from time to time. My car has a separate metal box over the cell and the lines where they are in the cabin. I got busted at a hillclimb (GCR rules) that I didn't have metal over my fuel lines (braided hose didn't count) so I did what any normal person would in the middle of nowhere. I built a cover using aluminum foil and riveted it to the floor here and there. Technically it was a metal cover. Rules were changed after that to be more specific.

-

ANOTHER Datsun Z/LS3/T56 Swap Thread

tube80z replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

Congrats on the first drive. You have an amazing project. I've helped a number of friends get theirs running but yet to have my own so I'm more than a little envious. Cary -

Using 5/8 bolt in place of spindle pin

tube80z replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

This is done time-to-time on various suspension bits, like a-arms. The one problem is that any bending will cause bind in a setup like this. So while it may have really low static friction when you put lateral and longitudinal loads into the bushing/bearing. Anyone who used the old Delrin/Al replacements up put on caster or toe in the rear would see that it often lead to wear patterns on the bushings. While the stock rubber bushings may not be ideal for our cars the poly versions are often upgrades. The downside is that unless you take very good care of them they'll lead to stiction (friction that Jon mentions) and that can lead to an abnormally harsh ride over certain sections of road in a street car or lead to weird handling irregularities. I'm not saying all poly bushings do this as there are clearly really good one. But unless you give them care and feeding you may run into some down sides. Newer street cars still use rubber bushings, which I used to hate. But now modelling has gotten a lot more refined and rubber bushings are designed to limit flex in one area and allow more in another axis. Think of running into a pothole and the suspension has a little extra lateral movement that allows for the jolt that you normally feel to be reduced. So you get a win/win. And even sportier models often use the equivalent of spherical bearings (BMW M cars) but they have proper seals for long term use. Hope that helps, I know this is somewhat off topic to the original post. Cary -

Using 5/8 bolt in place of spindle pin

tube80z replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

The spindle-pin bolt doesn't rotate. If it does then you have bigger problems. In a stock car the inner bushing tubes are all compressed by the spindle pin nut against the strut. The rotation comes from the rubber actually winding like a torsion spring. That's why it's typically stated in the manuals that you need to torque at ride height or off jack stands. As Jon mentions with poly the inner bushing tube is locked in place and the poly slides around the inner bush tube. A rod end setup works exactly the same. -

Using 5/8 bolt in place of spindle pin

tube80z replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

For a friends street car that used the toe-link design and rod ends on the strut side I used a special capture washer on the outer side so if the ball in the rod end is to pop out the control arm still stays attached. On the inner strut side I used a rod end spacer that's similar to a conical design. The bolt was torqued to 125 ft-lbs (grade-8 torque spec) and a Stover nut was used. I used the same setup for a number of race cars but used a nylock instead of the Stover to make it easier to work on at the track. One thing I should point out is that I used a properly long 5/8 fine-thread bolt. Meaning the rod ends were all supported by the non-threaded section of the bolt. I had to find some really long bolts and cut off the extra threaded section. I see a lot of the kits sold with bolts that have rod ends on the threaded sections, which shouldn't be done. -

Using 5/8 bolt in place of spindle pin

tube80z replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

The idea behind the spindle locking pin is that it is an extra safety mechanism. If you lose one or both nuts and washers on the spindle pin it can't slide out, assuming you have one that can actually be removed without the use of a large press. I have used a bolt in mine an no pin or similar mechanism and have no plan to ever again. That said I do regular bolt/nut checks on my car as part of their maintenance, which a large portion of the public think is either silly or a complete waste of time. Probably the same people who shouldn't be driving an old car without all the modern nannies or insert version of onstar they need when they lock themselves out of their car because it doesn't need a key to start. -

ANOTHER Datsun Z/LS3/T56 Swap Thread

tube80z replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

On an old formula car I used to have it did the same thing sitting overnight. I found that the supply line to the pump had enough oil in it to supply the bearings on start up. I always would spin the engine a few cycles without ignition or fuel turned on to build pressure and then start. My system had to be ran for some time to get the oil temp up and allow the pressure to come down to a reasonable level. Cold my system would make close to 100 pounds of pressure. Once everything was hot that would drop to about 65. -

Circle Track Sway Bar

tube80z replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

The problem with this when you adjust your ARB or turn the car you also change the motion ratio. I also don't know if the ARB would act as a filter for some of the frequencies the damper would normally see. -

Circle Track Sway Bar

tube80z replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Morgan Smith, who has the red Z with the large IMSA flares was running 550 lbs/in springs on his Z and using the 15 inch GY FA tires and the bushing died after a season. He was complaining the car was inconsistent and when he took the strut off I shook it and it rattled. The top busing was toast. -

Circle Track Sway Bar

tube80z replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

You'd be in revalve territory or very close. Just as an FYI try searching for "used race shocks" on ebay (https://www.ebay.com/sch/i.html?_odkw=penske+shock&_osacat=107057&_from=R40&_trksid=p2045573.m570.l1313&_nkw=used+racing+shock&_sacat=107057&LH_TitleDesc=1) You can get a few that aren't in the best of shape for 30 to 40 dollars and you can decide if this will work for you. I bought some Penske 7300 adjustable shocks with base valves, two extra sets of pistons, VDP pistons, and a s-load of valving shims for $1400. I bought new coilover tubes from Allstar, scored on a used shock vice, and fill cup. To do this on struts would be more than I have in the rest of the car. -

Circle Track Sway Bar

tube80z replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Unfortunately when I saw it I wasn't smart enough to know what I was looking at. A friend explained it later and they called it a Preston strut at the time. When I asked what the hell that was I was told Don Preston (maybe faulty memory) got fed up at IMSA and used coilovers that were mounted to the lower control arm and then hooked to the strut tower but used an old strut as the normal top suspension element. This was all to do with rules that said you couldn't do this or that. I can't remember if this was a 200SX Datsun or an RX-7. Both had a live rear axle. I think I was around 15 at the time helping my dad's friend who raced a super vee. I only noticed this because we were pitted across from each other. I wish I had pictures. I tried Google but I can't seem to find any. It may be one of those things that are lost to time. -

Circle Track Sway Bar

tube80z replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I know this has been the prevailing wisdom but it makes no sense. When it's wet the weight of your car and the suspension don't change. That's primarily what the shocks work with. While it's true the grip is lower it's the same as saying I need to valve my shocks for 50 MPH or I need valving for 100 MPH. I can anecdotally share I tried softening everything on the wet and ended up going back to my normal rebound and compression on the DA shocks I was using. I did remove the rear ARB and soften the front ARB but that was it. Left springs alone. I also suggest running your normal hot pressures when it rains. -

Circle Track Sway Bar

tube80z replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

In XP suspension is free. That means you could use an old strut and stay that way and add a rocker and use real coil overs. You won't get the advantage of an SLA but you wouldn't have to pay tons extra just because you have struts. This would be more like your ARB project as far as work goes. -

Suspension Setup Gurus....help...

tube80z replied to Ironhead's topic in Brakes, Wheels, Suspension and Chassis

There are two versions of these spacer/steering arm out there. The old version has too much of a pocket in the steering arm and can break if you use them on track days and autoxs. The other problem is they are flat. So any spacers under them aim for the wheel. A friend tried these and they wouldn't work when we went for enough of a spacer to lower bump steer. Personally this is one item I don't think I'd use aluminum for. One other general item I'd add around the spacers is to weld it to the steering arm and then use thin spacers to finish of the bumpsteer. This is stiffer then adding a spacer to the top and a long bolt torques down. -

Circle Track Sway Bar

tube80z replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Hi Clark the rod end works better in most cases. If you have a roller bearing it can still bind when the arm flexes in the middle. A common problem people run into is they install collars to hold the ARB in place but when it bends these hit the inner ARM mounts and cause bind. Give it 1/8 to 3/16 space and the binding stops. The rod ends are also great on older cars that may not be as stiff as a tubeframe chassis. I stole the idea from a Riley & Scott trans-am car but have seen it all over the place. The Realtime racing Acuras that raced in IMSA used this method as did a lot of older BTCC cars. All you have to do is mount a normal bar in a poly mount that's all greased up and see how much force it takes to move. Now jack on the end of a frame rail at the front of the engine bay and try again. I usually saw very different numbers. Sometimes 50 or more pounds from a fish pull scale. With rod ends that have been burnished it will be in the 2 to 3 pound range. That's free grip and helps make the car more consistent. Cary -

Using 5/8 bolt in place of spindle pin

tube80z replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

The one thing that hasn't yet been mentioned I'd like to point out is get a bolt long enough so only the shank is against the bushes. If you buy a bolt that fits it will most likely have threads in one of the bush ends. I don't think I'd recommend notching for the spindle pin as this will add a failure point and this system doesn't have the fail safe the stock system has. If you do decide to notch the bolt make sure to paint of put some corrosion inhibitor on it. cary -

What fuel pressure you are using? Webbers generally don't need much more than 1.5 to 2 PSI. These carbs need regulators if you're system is higher than that. When I used these on my old race car I would get flooding at anything over 2 PSI of fuel pressure. Sometimes on the street 2 PSI was too much.

-

curious to know what are the best L Series Transmission options now?

tube80z replied to primaz's topic in Drivetrain

Derek, Any chance you know the weight of the complete TL70 and/or the CD009? I'm looking at options for building a street card. thanks, cary -

I'd also recommend torrington bearings under the spring seats (top and bottom). Those will help front and rear as the suspension moves through it's range and they will allow the spring to rotate torsionally as it's compressed extended. I'm also not sure why there isn't more of a spacer on your camber plate to top hot that moves the load to the bearing. That's the silver bit Jon mentions. If you still end up needing more camber than you can get from all the adjustments it's possible to slightly bend the strut tube (i.e. crash damage) or pull the strut towers slightly closer together (assuming you don't have this already welded into a cage). This was often common on older cars where the rules didn't allow adjustments. One caveat is if you pull all the load into the monoball you'll either need to get better quality replacements or treat this as a wear item depending on use. The GC plates spread that load into the spherical machined surface on top.

-

280Z build w/ LS3 and 2015 Mustang spindles/8.8

tube80z replied to 280Z-LS3's topic in Gen III & IV Chevy V8Z Tech Board

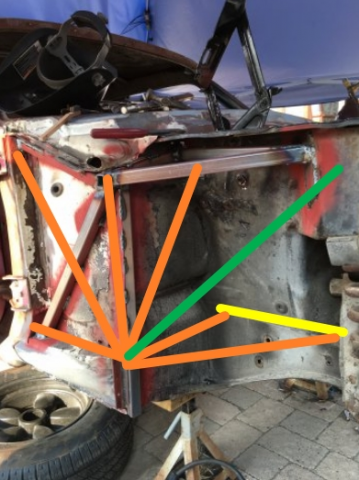

I'd only use metal of similar thickness to the frame rail, which I cannot remember off the top of my head. I can check today if needed as I have my race car cut up for a number of mods. You're spot on to why I'm doing all this. It isn't so much for stiffness, although that may benefit too. It's really protecting the passenger compartment from a wheel coming back in via this normally weak area. The main benefit I'm looking for is to add more crushable structure to this part of the car. I never gave much thought to any of this until I saw how badly the Falcon deformed in a fairly slow accident. Up to that point I was totally fine hurtling myself down the road at triple digit speeds thinking my cage and extreme skill would protect me. By making more of a box on the corner it connects the upper rail, inner rail, and top rail. The top rail now has a shorter span and should be stiffer. On my race car there's no cowl so I only have the firewall with no support. My cage will look overly complicated and heavy but only the required safety tubes need to be full thickness. The rest are of the same diameter but much thinner. The green line goes from the lower rail to the upper rail to the top strut mount. The yellow rail is tubing the sits on top of the normal engine frame rail, this is somewhat weird but based around some stupid SCCA rules that I'm working around. The tubes that connect the corner to the yellow tubes are what usually go to the TC pickup point. The idea behind all this is not only to make the car stiffer in torsion and bending but help protect the foot box in case I hit something hard enough to drive the wheel into this area. So it looks like you're well versed in all this. Nice work, BTW. Hope this helps, Cary -

280Z build w/ LS3 and 2015 Mustang spindles/8.8

tube80z replied to 280Z-LS3's topic in Gen III & IV Chevy V8Z Tech Board

I don't think you need to go that large. I'd use the same tube as you would for a strut bar for the purely torsion stressed members unless you already have the material. It will just weigh a little more in the end. I think you have a couple options. You can do it in tube similar to what you have or was used on BJHines car. The other is to make a larger torsion box out of sheet in similar thickness as the rest of the car. Look at the convertible torque box mod for Ford mid-to-late 60s Mustangs and Falcons. They have a very similar unibody design to the Z. In those they build a box that goes straight down from the firewall and then back into the floor. This connects to the engine bay side. Here's a couple of links to give you the general idea https://ironhydroxide.blogspot.com/2017/04/boxes-of-torque.html and https://ironhydroxide.blogspot.com/2017/05/boxes-of-torque-part-dos.html. I've also seen this extended down to the level of the outer rocker lip and boxed into the inner rail. Many of the IMSA Zs boxed in the outer section from the upper rail to A pillar down to the rocker. This makes that more of a torque box out of that section and can tie in nicely with something similar to the convertible Mustang mods. Getting across the tranny tunnel is going to require a brace under the bellhousing area or you add internal rails that go from the front frame rail up and over the tranny tunnel and down to the next side. If you look at newer cars you'll see they have integrated a 8 to 12 point cage into the unibody design. They just do it with folded metal rather than DOM tube. For a street car that may do some track work I think meshing the torque boxes with the tubes in the image above would be a good way to go. The new Mazda RX8 is a very stiff unibody compared to all their previous cars. If you look at images of it and compare to older models all these little details start to pop out. However you go I really like what you've done. I need to get some projects out of the way so I can get back to cars myself and put this year behind me. Hope that helps, Cary