NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Actually the thought crossed my mind. But stating equal distances implies equal diameters, hydraulically speaking. You can only elucidate so much on these forums. Besides that, he sad that he was not in spec on distance, by the FSM. 0.4 / 1.378 = 0.29. That's a giant slave or a tiny master. Reman cylinders are known for grit grime and poor quality. He might have a dust boot full of fluid.

-

Might get more response if you just asked for the whole backing plate. Not positive also, but they might vary with year. Later 280Z drum brakes are different from early, for example.

-

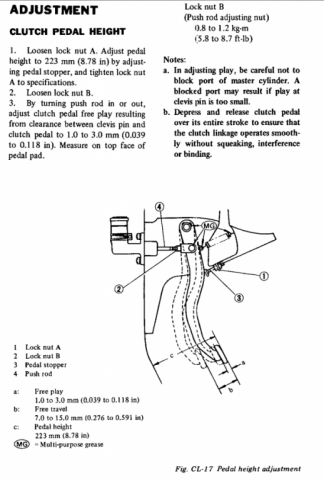

If you've done all of these things, then check the slave cylinder dust boot for fluid. It might be leaking. The reason that the pedal adjustment is so important is that the slave cylinder piston will only move as far as the MC piston moves. That's how hydraulic systems work. If you only get 0.4 inches of movement at the slave cylinder, and there's no air in the system, and the cylinders are the same diameter, then the MC piston is only moving 0.4 inches. That's the basic principle. If you want to get rigorous, measure the distance the end of the MC rod moves, at the pedal. It should be 0.4 inches, if you have a properly bled, non-leaking system, and the slave only moves 0.4 inches. Slave follows master. If you have more movement at the master than the slave, there's a problem in the hydraulics. Break it in to its two parts, mechanical and hydraulic.

-

If you have tiny fingers or are good with a tools, the simple way to check the MC rod length is to remove the clevis pin. If the clevis hole isn't lined up with the pedal pulled up to its stop by its spring, it's probably too short. Actually, that adjustment should be made when the MC is installed. Makes it much easier to get the pin installed. p.s. if you have fat fingers or large hands, you can run a thread through the hole in the clevis pin, then run the thread through the pedal and clevis holes, and pull the pin in to place.

-

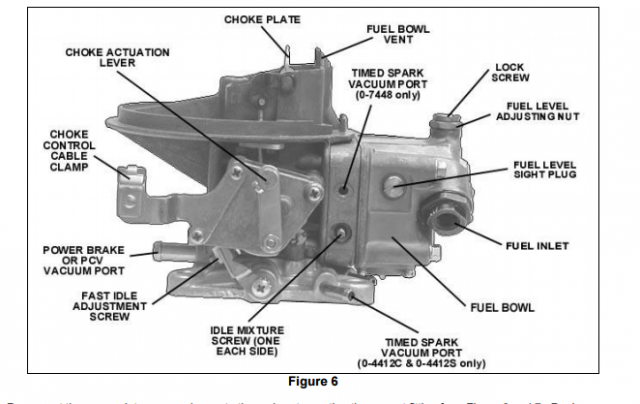

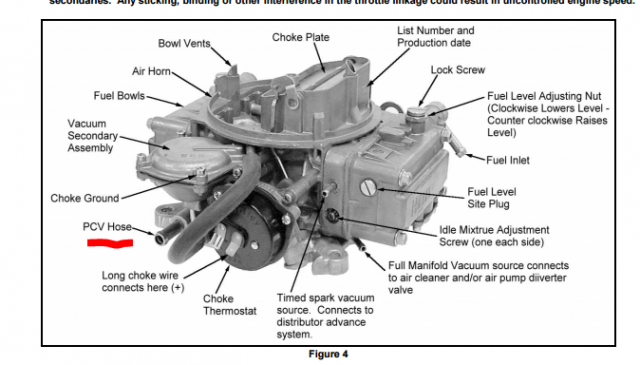

AZC shows a simple way to get PCV. Not very sophisticated, it's before the carb and depends on vacuum inside the air filter housing to create vacuum. The worse the air filter the better the PCV pull. Plus it oils up the carburetor. http://www.arizonazcar.com/cableinstall.html You could plumb the manifold and use a PCV valve. That's how Nissan did it with the 240Z's. Read up on them and you'll get some ideas. The carb stays clean, gases are purged. The crankcase has to be sealed, so you can't run a breather and a PCV. Edelbrock has a PCV port on the carburetor itself - http://www.edelbrock.com/automotive/misc/tech-center/dl/carb-owners-manual.pdf Looks like some Holley's use the same port for PCV and brake booster. You could do that. http://documents.holley.com/199r7950-7rev7.pdf Of course, if you use the 0-8007 390, you could just use the PCV port already there. http://documents.holley.com/199r8108-2rev4.pdf A sealed crankcase and a PCV valve is probably the cleanest way to go. The problem with the sealed crankcase is that you need a way to let off pressure from blowby at high RPM, open throttle. Like the EFI systems do. Not sure how the carb guys do that. Probably why they run them open with catch cans. Could be that they just run the hose to the carb, but no PCV valve. Seems like the power brake system would get oiled from crankcase fumes if it's T'ed in there. If I was building a system, and wanted it to stay clean, but avoid over pressure in the crankcase, I'd probably put a check valve on the valve cover with a breather, one-way vent to the outside, and use a PCV valve on the manifold with the carburetor port. Or run the valve cover line to the air filter, like AZC shows. Still with a check valve though. Not sure where you'd get that valve. There's probably a thread out there somewhere in which somebody has gone over all of the PCV permutations for a carb setup.

-

I would guess that this is your problem. I'm not sure what you mean by "any if possible" but the clevis at the master cylinder rod can be adjusted where it attaches to the pedal. You can do it with a pair of pliers. Loosen the lock nut and turn the rod to make it longer. Run it out until you get proper play at the pedal.

-

Yes, the internal clips were used up until the VLSD diff's I believe. VLSD has clips on the axles, older open and CLSD had internal clips. They should still be in yours. They were probably part of the problem you had removing your axles. Might be damaged by now. The clips keep the axle located in the diff. Otherwise it would be a battle between the halfshaft compressing and extending or the axles moving in and out as the distance between diff and hub changed.

-

You might have a memory from when you had it part of what is involved in "going in to gear". Not much. A coupling sleeve with internal teeth moves over a synchro ring and the external dog teeth on the gear being engaged. Three little pieces of metal (inserts) compress three little springs along the way. So rust may be a factor since the coupling sleeve and the gear will rust. If the synchro cone on the gear rusts that will hinder the synchro ring aligning the teeth. Could be a factor. The shifting rods can rust also. Aluminum can build up an oxide layer also, so the holes might be gummed up. So, if ti worked "okay" years ago, it will probably come back to at least that level. I had an old transmission that sat for years, that worked itself in to better shape after a few miles of driving and picking the right fluid. My best guess was rust on the parts that need to be smooth to work right. Your best path forward might be to just drive it. Start it in 1st gear if it won't engage with the engine running. Match RPM while you're trying to wear it in. For $80, not much to lose. Here's a video of a guy shifting his FS5R30A transmission, with both cases removed. Lots of other good pictures also. http://beergarage.com/PathTransmission9Shift.aspx

-

Remove the drive (propeller) shaft and turn the output shaft by hand and you'll take out all of the other possible grinding possibilities. It's a pretty simple problem. Don't forget to drain the fluid first to avoid a mess. Look for chunks and fine shiny stuff while it's out.

-

http://www.silverminemotors.com/datsun/datsun-240z/brake-upgrades https://technotoytuning.com/nissan/280z/rear-big-brake-kit-240z-260z-and-280z https://www.google.com/webhp?tab=ww&ei=dq5PVNe5B8j8igLU9ICABg&ved=0CAMQ1S4#q=wilwood+240z

-

Either you messed something up or it was messed up when you got it. Hope's probably not going to help you. Stiff shifting might get better, but awful grinding rarely goes away.

-

Stock Car Mafia's '78 280z LS2 Build

NewZed replied to Stock Car Mafia's topic in S30 Series - 240z, 260z, 280z

Just recalled that some (maybe all?, 2 v 4 pinion?) CLSD's are open through the center of the diff. So if you have one axle out the other can be knocked out from inside with a drift. Don't get the point of the drift stuck in the lathe spindle point (whatever it's called) hole in the end of the shaft. -

GC 280Z is now too low.

NewZed replied to kerrys914's topic in Brakes, Wheels, Suspension and Chassis

You'll only preload the spring if the shock absorber/strut is fully extended. Depends on your springs and spring rate and how high you lift the car. The stock Z car strut has some preload with no weight on it, but a low rate that lets the car drop under its own weight. There are many interactions to consider. -

Stock Car Mafia's '78 280z LS2 Build

NewZed replied to Stock Car Mafia's topic in S30 Series - 240z, 260z, 280z

An oiled chisel, or a few of them, will work as ramps to lever out the flange. Stick them between the housing and the underside of the flange and tap them in. You might bend the edge of the oil seal but you're probably replacing it anyway. -

I'm just wondering. I can see letting an opportunity grow in to something bigger. But if jdmpowerhouse was in the works from Post #1, that would be a bit disingenuous and make you think twice about the whole story. If you pay jdmpowerhouse for the diff, it wouldn't be a surprise to find that the mfactory warranty is void. Better check that mfactory will honor a second-hand warranty. If jdmpowerhouse is a small LLC, they won't have the resources to honor any warranty, let alone a lifetime policy. One bad diff could wipe them out. They only have two products shown on their brand new web page. The road to hell and all that... see Senza Pari.

-

Don't forget the 280Z mustache bar and curved transverse link (aka dog-bone).

-

Sent My N47 Head to The Machine Shop.....

NewZed replied to FrappNasty's topic in S30 Series - 240z, 260z, 280z

Sounds good. I'd worry about the funky lights-throttle interaction now. -

http://www.jdmpowerhouse.com/ Hey man. Things like the above are a little worrisome. People have been on the site pretending to be professionals and taken money for crappy products. Now you're saying you're just a guy and his dad trying to help the community, but you have a professional-looking web site going up. So which is it? Are you a business, or just two guys playing with cars?

-

It attaches to the same spot it was at with the switch installed.

-

GC 280Z is now too low.

NewZed replied to kerrys914's topic in Brakes, Wheels, Suspension and Chassis

You can have gap OR tire diameter, if you set a certain distance from the ground. There's no way around it. -

GC 280Z is now too low.

NewZed replied to kerrys914's topic in Brakes, Wheels, Suspension and Chassis

This means your tire diameter is too small. Get the tire diameter that gives you the body height and gap that you want then fit the suspension. -

Good luck. The 240Z R180 pictures in the FSM's show the flanged axle. Looks like Nissan was shifting to the complete one piece halfshaft, similar to the ZX CV halfshafts, for the 280Z's. Learned something new.

-

I think that you just need a set of these. But the R180's confuse me because I've never had one. http://www.ebay.com/itm/Datsun-nissan-R180-axle-axles-yokes-240z-260z-280z-280zx-1970-1971-1972-1973-/252315140130?hash=item3abf278022:g:16IAAOSwoudW4Okt&vxp=mtr

-

I think that you just need R180 bolt-in axle flanges, instead of bolt-in half-shafts. I don't really understand which cars have which. Your thread title is misleading, your problem has nothing to do with "automatic" besides the fact that they came with R180's. jmortensen's thread shows what you want yours to end up looking like. Clip in versus bolt-in. Don't know how to get there. He seems to imply that the older R180's used the bolt-in flanged axle. So maybe you just need to find an older R180 and take the bolt-in flanged stub axles. http://forums.hybridz.org/topic/49194-differential-cv-lsd-hp-torque-r160-r180-r200-r230-diff-mount/ John Coffey's work implies that the early R180's had the flange you want also. I think that you just need an old R180. http://forums.hybridz.org/index.php/topic/78123-subaru-wrx-sti-r180-side-axles

-

Just curious, but post pictures of the Ermish R180 kit. They don't really show the parts on their site. http://www.ermish-racing.com/custom-suspension-items