NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

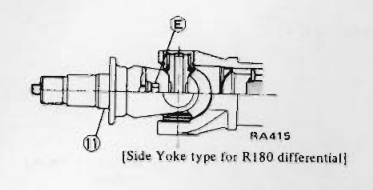

You might give your u-joints a good look. It's hard to tell that they're loose without really prying on them. Stick a screwdriver between the yokes and reef on it with a bright light to see movement. Why do you think that your R180 halfshafts look different from the ones in the FSM? You can see the bolt head. Maybe you've been looking at the Subaru R180 pictures.

-

Transmission grind, slave adjustment?

NewZed replied to jersey280's topic in S30 Series - 240z, 260z, 280z

The red above would be what's called pumping up the system. Air in the system is overcome by pumping. The hydraulic system is essentially self-adjusting if the mechanical parts are correctly adjusted. There's no adjustment at the slave cylinder. I'd check the play at the pedal first, especially since you installed a new MC. You can adjust the rod out without removing anything, just use pliers and twist it in place. And rebleed to remove all air traces. You might have a small amount of air and too much mechanical play. -

Unfortunately it's not uncommon for a new cam to get damaged/destroyed. A few people on this forum have had brand new cams get flattened. there's general knowledge and there's some tricks but it seems to come out of nowhere for some people. You can install an internally oiled cam in a previously externally oiled cam head. The oiling depends on the cam, not the head. From my perspective DatsunSpirit is East Coast.

-

L28ET swap 240z runs rough won't take throttle

NewZed replied to motomanmike's topic in Nissan L6 Forum

You should put your problems in your words just to be sure. Besides that, the OP's description is 5 pages back. And, he described a multitude of problems. It would be odd if you had all of the ones he did, identically. Even better, start a new thread. -

Bagged, generally when people offer very specific advice it helps if you address those specific items in your reply. Matt gave two targeted things to your exact question, and I'm not sure that you addressed either. You didn't address spark output, and I'm not sure that his "Fixed Angle" is in the same category as your "Use Table". Isn't the other option "Fixed Timing" in the "Fixed Advance" box? "Fixed Angle" might be a different parameter. Find the box that has Fixed Angle in it. Anyway, he covers many forums, I believe, so might not be back right away. Get the specifics and get back. Good luck.

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

Thanks Matt. That's two specific things to check that should help him out. I sent Matt a question specifically about using the 83 CAS. For my own illumination. I would guess that the settings need to be right even with the DIY wheel. With luck, a couple of clicks should get the OP past this problem. And on to new ones. Edit - weird how sympatico CM and I are. Same timing....

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

All that I'm saying is that mobythevan made the 83 turbo CAS work, and his writeup was so good that DIYAutotune includes it on their web site. Along with other work by him. If you follow his advice, you should get his results. And, as I understand things, your Haltech application is simulation only, not actually running an engine, so not really relevant here. I get the urge to be knowledgeable. I'm throwing out ideas and offering possibilities. Nothing is certain, only the OP can determine that. When the OP comes back with a "win" we can all make a note, for future reference. This is all just words and thoughts until that happens. If it looks like I don't respect what you're writing it's because it doesn't fit my own personal criteria of "relevant". The OP can choose the advice he wants to follow. That's the beauty of the internet. You can ignore the people you don't agree with.

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

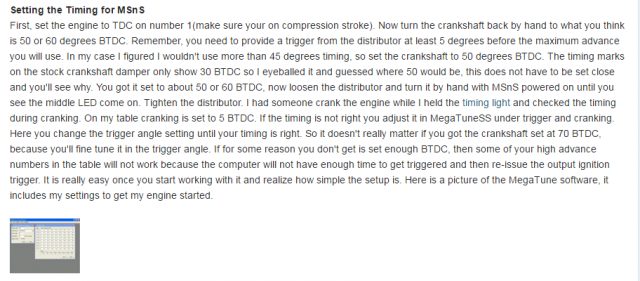

Basically you're just giving MS a CAS signal way ahead of time. It does its calculations and grounds the coil after a certain wait time, to trigger the coil a certain number of degrees ahead of the Initial timing number that you set using the advance table fixed timing. I took a picture of where you might be going wrong. You never talked about physically setting the Trigger position of the CAS, as Mobythevan describes. Not clear that the 60 degrees you show in your screen grab actually applies to a 60 degree CAS shift. Your system has no room to work in, to set timing advance.

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

Here's the part I remembered from the past (reading only) about how MS does advance. It's in the Mobythevan writeup about using an 83 turbo CAS/distributor. You may be setting your initial timing incorrectly, leaving no room for advance. http://forums.hybridz.org/topic/23244-megasquirtnspark-mssmsns-installation-guide/

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

Another thought - "Burn" isn't burning. You're putting a number in a TunerStudio box, then rotating the distributor to make it match the number in the box. You're changing the engine to match the TunerStudio numbers. But the Megasquirt ECU doesn't seem to be reading what TunerStudio should be sending it, when you click "Burn". Basically, what you're saying is that, overall, the Megasquirt ECU isn't obeying the TunerStudio commands. Could be just a communications problem between your portable PC and the MS ECU. I'd find a way to confirm back and forth communication between all components. I don't know what that confirmation would be. But it seems like your MS ECU has enough to run your engine but isn't being controlled by TunerStudio..

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

That's right, I am Zed Head on classiczcars.com. I'm saying that what the OP has should work. As a basic distributor. Like DIYAutotune says. He hasn't even got to "basic" yet and you have him rebuilding everything he has. Keep it simple. DIY didn't say anything about band-aids either.

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

Just had a thought about your jumpy timing at idle. Are you triggering on the proper edge of the holes? Maybe Megasquirt can handle the wrong edge at idle but can't use the advance curve properly. Depends on who write the code, someone might have added a feature to protect the engine if parameters aren't coming in correctly. A first-derivative algorithm might fail if the points don't fit the curve. Another odd possibility is that the knock sensor protection is kicking in and stopping advance. Still spitballing.

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

Running 280turbo inj. on a Z20/24E hybrid engine.

NewZed replied to spiff's topic in Nissan 4 Cyl Forum

You can carry a turbo in the back seat and call the car a turbo car. It won't make more power though. -

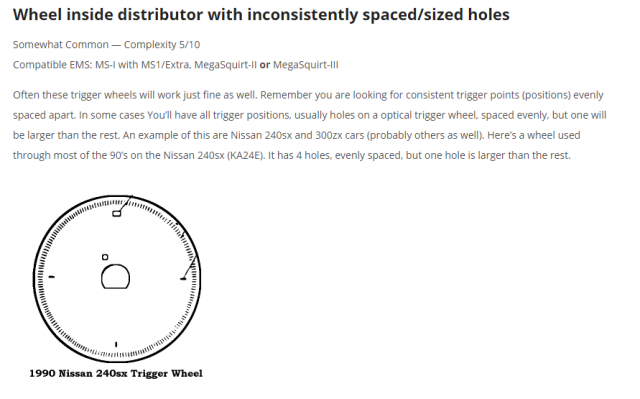

Moby implies that the 83 wheel will work. He did his writeup before the DIY wheel was available. http://forums.hybridz.org/topic/23244-megasquirtnspark-mssmsns-installation-guide/ You have spark so Megasquirt is seeing a crank signal and using it. I wouldn't make it more complicated than it is. Seems more like you have a software problem, Megasquirt is not doing what it's supposed to do. Megasquirt uses "prediction algorithms" to move the timing. Don't know how knowledgeable these guys are though. It's surprising how little information is out there about this. Some programs use a retard method, where you set the base trigger way advanced, like 60 degrees, others use the next cycle. Here's an interesting thread about it. http://74.124.198.224/~micro/viewtopic.php?t=17518 Here's a Hybriz response but moby doesn't really seem interested - http://forums.hybridz.org/topic/44373-predictor-algorithms/ Of course, it's not uncommon to go off on a tangent and find a problem solved without really understanding how it happened. Here's another thread showing how confusing it can get, and probably why nobody publishes anything about how the various algortihms work. Best to leave a mystery. Still might give you a new direction. http://www.msextra.com/forums/viewtopic.php?f=131&t=39578&start=0 Here's another comment (picture included, but you have six slots, not four) about using the basic evenly spaced trigger wheel, which is what you have and which seems to be working. Using a different trigger wheel should leave you with the same problem, if it's the only thing you change. In principle https://www.diyautotune.com/support/tech/other/megasquirt-ignition-control/ Anyway, the suggestions to try something else don't seem to be using the fact that your trigger wheel is triggering and the engine is running. The suggestions don't follow the facts.

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

Running 280turbo inj. on a Z20/24E hybrid engine.

NewZed replied to spiff's topic in Nissan 4 Cyl Forum

Why? Factory EFI systems are designed for certain flow rates. You'd have to adjust the system back to the same performance you'd get from the stock injectors. When you're all done, no benefit. -

Sequence of events when setting parameters may matter. Seems like you're taking all of the right steps. Here is DIYAutotune's recommended method - https://www.diyautotune.com/support/tech/other/base-timing/

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with:

-

Was I being an ass? I'm not seeing any fuel lines there. The Snipping Tool and a red line would help. How would the fuel return line be connected to the intake manifold, with a valve and some other fitting? Not getting it.

-

You are starting from waaaay behind. That's the coolant hose from the radiator outlet to the water pump inlet that you have your finger on in that picture. Nothing at all to do with fuel. No offense, but you need to be careful before you start messing real fuel lines. Fix the fuel fill hose problem first. It's essentially in the cabin with you so any leakage at all is raw fuel smell. Don't mess around in the engine bay until you spend some time studying. " I also found out that the lines from the fuel fill to the tank leak when slightly overfilled and I am correcting that now." Good luck.

-

CONFIRMED L28 with RB25 Flywheel and 350Z Clutch

NewZed replied to 83turbo280zx's topic in Nissan L6 Forum

Got curious. One of several - http://forums.hybridz.org/topic/112994-rb25-flywheel-to-l-series-question/ -

Here's normal sound and normal speed. Don't know who it is.

-

Mine sounded "cammy" when it was running rich. My neighbor thought it had a performance cam. It doesn't. Raise the idle speed, to at least spec., let it warm up and see what you think. You're off=spec. right now (low idle speed). so it's going to sound off. All engines sound about like that when the idle is too low. You've checked a lot of stuff, might as well change the idle speed to where it's supposed to be.

-

Idle speed is low. Not good for oil pressure or alternator charging. Beyond that you'll need to define what you mean by "off".

-

Same head casting number (design/style), and same head gasket?

-

Seems like there's a setting somewhere that isn't right. The ECU and software adjust timing by changing the coil grounding moment in relation to the base timing. So, the program just isn't controlling the coil ground like it should. The distributor is distributing and the CAS inside it must be communicating with the ECU to generate the base timing signal to create a spark. The engine runs. Could be that there's an input variable that is so far out of range that the software defaults to no advance. Maybe the MAP variable is set wrong. Maybe temperature reading? http://www.megamanual.com/ms2/ign_timing.htm Just offering ideas, and picking up some knowledge myself.

- 69 replies

-

- Megasquirt

- Ignition

-

(and 1 more)

Tagged with: