NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Has anybody have problems dealing with ZCAR DEPOT?

NewZed replied to toolman's topic in Non Tech Board

Forgot to say, he's a member here, but he doesn't respond to notifications either. @zcardepot.com -

Has anybody have problems dealing with ZCAR DEPOT?

NewZed replied to toolman's topic in Non Tech Board

How long ago? I've read a few things. The company is run by one guy and I think he's getting too big to keep up. -

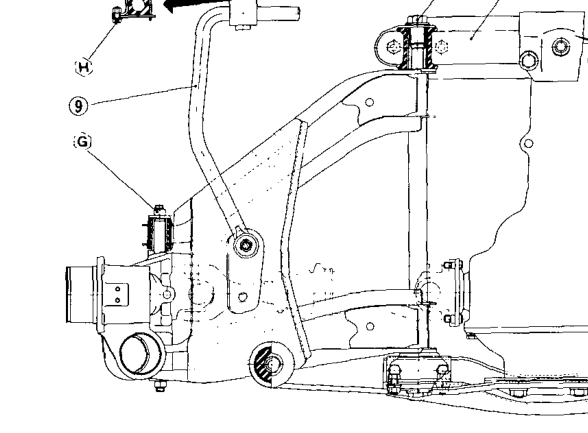

You're probably thinking of dropping the strut and letting it swing out while still attached to the inner mounting points. Sometimes it's possible to do that, sometimes you still need a spring compressor to get enough room to get under the fender lip. Then, even if you do get it swung out, you still need to remove the spring, and gland nut and strut guts (stock internals or aftermarket shock), before cutting the tube and installing the BC parts. How you decide to do it depends on how much room you have and how good you are at figuring things out. It's actually somewhat convenient to have the strut attached to the car, if you don't have a bench and vice and fixtures. The guys are right though, if you're asking about the gland nut and avoiding spring compression, you'll want to do some more studying before starting. This one? https://www.bcracing-na.com/product/br-series-coilover-datsun-260z-280z-1974-1978

-

Unique Factory Oil Cooler O-ring, what is the part number?

NewZed replied to himself's topic in Nissan L6 Forum

Did you win? It's a gasket. https://www.google.com/search?q=oil+filter+gasket&rlz=1C1SQJL_enUS862US862&oq=oil+filter+gasket&aqs=chrome..69i57.3881j0j15&sourceid=chrome&ie=UTF-8 -

Unique Factory Oil Cooler O-ring, what is the part number?

NewZed replied to himself's topic in Nissan L6 Forum

p.s. the Nissan filter would be the obvious starting point. p.s. 2 that gasket would not normally be considered an "O-ring". It's a gasket. O-rings are more complex, although a quick Google shows that the term is being dumbed down (no offense) to refer to any gasket that is round. https://www.parker.com/Literature/O-Ring Division Literature/ORD 5700.pdf -

Unique Factory Oil Cooler O-ring, what is the part number?

NewZed replied to himself's topic in Nissan L6 Forum

Is it a Nissan part or aftermarket? Seems like you could peel the gasket out of a filter and it would work, if you find the right filter. A sensible engineer would design the seal to match an oil filter seal, since the sealing surface is the same. -

Question about a SpeedHut Tachometer Swap on a 1970 240Z

NewZed replied to JMF 240's topic in S30 Series - 240z, 260z, 280z

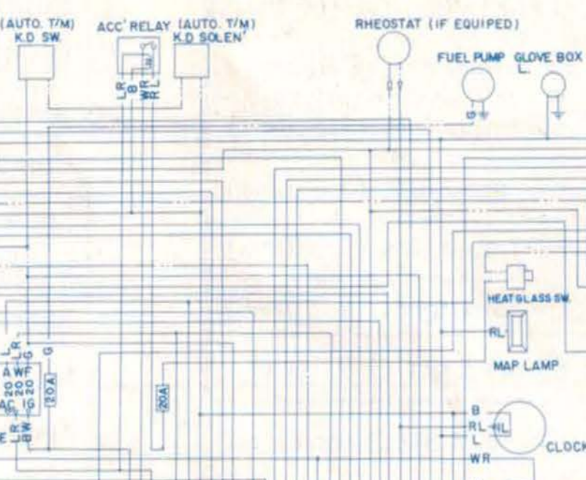

That sounds correct. If you know the colors you can just bridge them earlier in the harness, no need to get all the way up there. Unfortunately Nissan changes colors at the connections for some reason so the wires in the harness might not be white. -

Question about a SpeedHut Tachometer Swap on a 1970 240Z

NewZed replied to JMF 240's topic in S30 Series - 240z, 260z, 280z

Post up the instructions for the Speedhut gauge. The white wire on the right of your picture, with the loop in it, is the one that the current passes through to the ignition system. It's the current that causes the 240Z tach needle to move. But there is also a voltage sensing tach that just has a wire from the negative post of the coil that terminates at the tach. You need to know what type Speedhut is using. Here's a bigger diagram than the tiny snippet you posted. https://www.classiczcars.com/files/file/1-240z-wiring-diagram/ -

Using 5/8 bolt in place of spindle pin

NewZed replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

I wonder why somebody hasn't designed a solid replacement. All steel. -

Using 5/8 bolt in place of spindle pin

NewZed replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

You guys are right about the stock parts. Crushing the control arm ears would not happen. With those parts it's just the simpel safety factor of breaking the bolt and having it slide out. I'm still a fan of thinking things through to the extent that a person can. It's more than just "throw out the spindle pin and slap a 5/8" bolt in there instead". With the PU bushings that most people install when they remove their spindle pin the control arm ends slide forward and backward on the bushing. Does the nut and bolt need a proper sized washer to support the bushing or control arm surface? What size should it be? Worth thinking about. Most of the PU bushings are too thick to fit in the gap. Should they be trimmed or should the control arms be spread to squeeze it in there? Why didn't the PU guys get the PU part right, so that it fits? Is the sleeve that they supply right? The first guy's post was about the InvincibleExtremes setup. Might be far from the crusty old stock Nissan bonded rubber parts. You'd really have to see the parts to know if the Nissan design is being followed. There's an assumption that he does do but so far it doesn't look like anyone has actually got theirs together yet. -

Using 5/8 bolt in place of spindle pin

NewZed replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

The control arm will be moving in relation to the hub casting as the suspension moves. The bolt and nut will be clamping the "ears" of the arms against the hub surfaces. Regardless of whether the arm ears deflect enough to make the surfaces contact my point is that the bolt is an axle, or think of it as two separate axles, one on each end. There is rotation around each of those axles. Again, over-thinking, but that's part of the point of a forum. To be clear though, I think that gnosez is talking about the simple act of replacing the spindle pin with a 5/8" bolt, no mono-balls or rod ends. You might be talking about a different application. -

Using 5/8 bolt in place of spindle pin

NewZed replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

Torque specs are set to get proper clamping force from the nut and bolt. But this application uses the bolt as an axle. It's not meant to clamp. You'll be clamping down on a moving bearing surface. I don't think the common torque specs apply. -

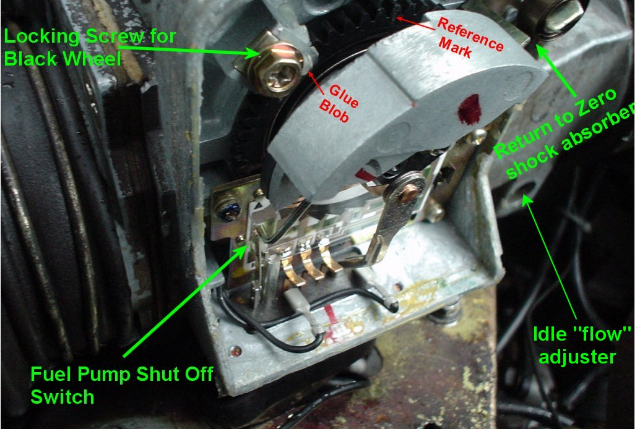

280z 1976 stalls after startup. Throttle body switch?

NewZed replied to Sjoost's topic in S30 Series - 240z, 260z, 280z

1976 has a switch in the AFM that controls the fuel pump relay. When you start the engine cold the idle speed is higher and air flow keeps the switch closed. As idle speed drops air flow does too and the switch might be closing. You can check that possibility by taking the black cover off of the side of the AFM and manipulating the counterweight by hand. Ot you can just watch the switch, it is just two very small contact points attached to a piece of stiff wire. You can bend the wire to adjust the switch if needed. Another check is to just turn up the idle RPM and see if that makes a difference to keep the pump running. Here's a picture. Don't mess with any of the things shown in the link, he's showing how to fix an AFM that has been messed with. https://www.atlanticz.ca/zclub/techtips/afm/index.html -

Using 5/8 bolt in place of spindle pin

NewZed replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

Here's some overthinking - it should really be a 16mm bolt. -

Using 5/8 bolt in place of spindle pin

NewZed replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

I was responding more to gnosez's comment about "over-thinking". He has a tone of superiority, but really he's just a guy who decided to use a bolt, apparently because it's easier and cheaper. Nothing really superior about that. It's just a choice. The whole point of these forums is to generate things to think about, but the value of those things is opinion. -

Using 5/8 bolt in place of spindle pin

NewZed replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

Most of the discussion about the spindle pin and locking bolt is about why Nissan did things that way. And, as often mentioned, just because something didn't fail doesn't mean it's better. There are many areas on the Z where you could just use a cable or a chain or drill a hole and use a bolt. In the end the car owner needs to know what they're trying accomplish and take responsibility. The internet is full of all kinds of starting points to think about but it can't decide for you no matter how many posts are posted. -

Is this a good project? I had the same year ZX in high school.

NewZed replied to motorpoodle's topic in S130 Series - 280ZX

It's the cost of parts needed to bring up the value that will get you. Nickels and dimes. Mustangs and Chevys have a huge aftermarket network making parts. The 280ZX, not so much. If you're really thinking about investment then a simple spreadsheet of costs should throw some light on it. Here's a couple of web sites that sells ZX parts, for starters. You could probably just get it running and clean it up for a small profit. But restoration will be expensive. http://www.zcarparts.com/ https://zcardepot.com/collections/280zx Look at the quality versus price on your future competition and estimate how much you will have to spend to get there. Good luck. https://bringatrailer.com/datsun/280zx/ -

Is this a good project? I had the same year ZX in high school.

NewZed replied to motorpoodle's topic in S130 Series - 280ZX

You can almost certainly get it running but almost nobody makes a profit restoring these old cars. Get it running >>> yes, make a profit >>> not likely. -

Actually, he does have a kit. I didn't go far enough down the page. https://zcardepot.com/products/r200-differential-rebuild-bearing-seal-kit-280z-280zx-300zx?_pos=61&_sid=f9b96a786&_ss=r

-

I've never seen a kit. This guy, below, has parts you might need. They're pretty durable and don't often even need rebuilding. The Factory Service Manual has a section on rebuilding the diff. https://zcardepot.com/search?q=differential&type=product

-

https://zcardepot.com/products/oil-pump-drive-spindle-oem-280zx-turbo-81-83?_pos=17&_sid=d035dc3a5&_ss=r

-

I always thought that they were connected but never figured out exactly how. I would have put this in the other post but there is no Edit function.

-

That's not good. The BrokenKitty site is still active. http://www.brokenkitty.com/index.htm