NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

I misunderstood the FSM, it seems that it probably adjusts to engine conditions, as they say. You said that you just wanted to get the engine running before removing it. Jumping the pump is the way to do that. Good luck, whatever you end up doing. Parts for the old ECCS system are hard to find so Megasquirt or other standalone is probably more dependable in the long run.

-

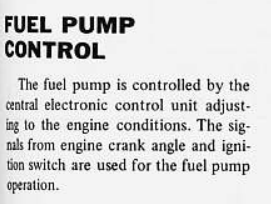

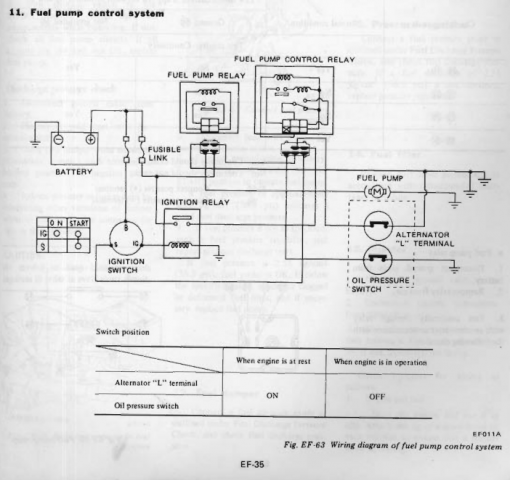

Is this a thing? "the clicking fuel pump relay syndrome" classiczcars.com has FSM's that you can download. 1981 is still primitive. I think the fuel pump just runs full speed all the time. Might as well jump it if you just want fuel pressure. Here's the section from the 1981 Turbo Supplement. You should get a 5 second prime, or you can pull the starter solenoid wire and use the Start circuit.

-

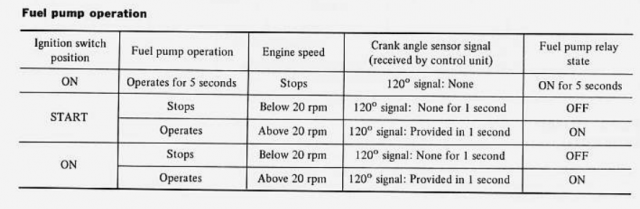

Do you know why it was parked 20 years ago? I think that it's fairly common for people to get angry when they can't get in to reverse, because of a bad clutch cylinder, and to force the shift lever. Damage to the fork seems possible. You can get to the reverse/5th fork without removing the front case.

-

Eibach Springs - Front sits high... *pics*

NewZed replied to PCressey's topic in Brakes, Wheels, Suspension and Chassis

I just realized a possible solution. A "cold air battery". CAB (trademark pending). Move the battery in front of the radiator. The extra leverage should drop the nose a bit.- 48 replies

-

- suspension

- springs

-

(and 1 more)

Tagged with:

-

280z 1976 stalls after startup. Throttle body switch?

NewZed replied to Sjoost's topic in S30 Series - 240z, 260z, 280z

I don't know how much modifying you want to do but here are a couple of links about replacing your ignition module and coil, and getting rid of the ballast resistor. All of which will give you a stronger and more dependable spark. These old ignition modules are dying at a regular rate after 40 + years, and the ballast resistors go bad also. It's easy to do and easily reversed if you need to. And pretty cheap. One of the guys is from your area of the world. https://www.classiczcars.com/articles/electrical/replacing-the-280z-tiu-with-an-hei-module-r67/ https://www.classiczcars.com/profile/25507-sscanf/ -

280z 1976 stalls after startup. Throttle body switch?

NewZed replied to Sjoost's topic in S30 Series - 240z, 260z, 280z

I kind of overlooked that. You definitely do not want to see sparks anywhere in the engine bay. The spark jumping to the negative terminal is definitely bad, it might be a sign of bad wires, or the center wire not completely seated in the coil. So you need to fix your wires for sure, make sure the center wire is firmly seated in the coil and the distributor. But you also need to check the rotor and the distributor cap also. Spend some time making sure those parts are in good shape. Even having your spark plug gap set too wide can cause the spark to jump to where it doesn't belong. The spark will take the easiest path to ground. One side effect though of the coil discharge jumping to the negative terminal is that it can damage your ignition module, since the negative terminal is connected to the module. Something to be aware of. But first, get some good wires, and tune-up parts and get the system to the point where the spark only passes through the spark plug wires. You should never see or hear sparks in the engine bay. -

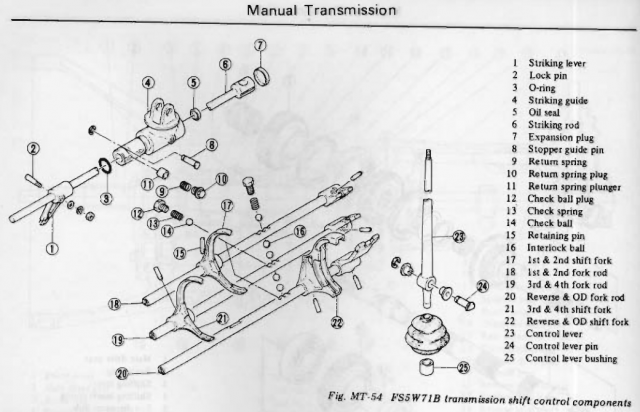

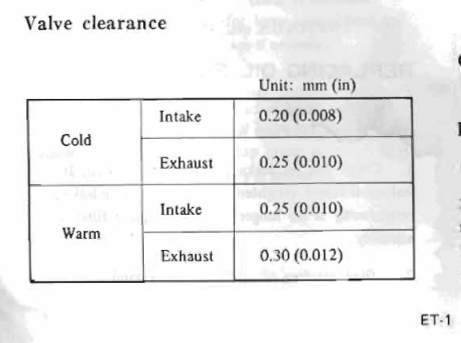

jonbill knows more about performance engines but it looks like the camshaft might have been reground. The base circles are close to the main shaft. You can measure lift if you want to be sure but it doesn't really matter much. Also you can see that the wipe pattern is close to the edge of the lobes, so the shaft has been out and back in and might be off a little bit. If you take your calipers and measure the area of the lobe that has no rise, then measure the lobe height, the difference should be 7 mm if it's stock. Big picture-wise though, you might as well just reset the lash to factory specs, and run it. No obvious problems there and the engines are generally durable.

-

280z 1976 stalls after startup. Throttle body switch?

NewZed replied to Sjoost's topic in S30 Series - 240z, 260z, 280z

Might be that your ignition module is going bad. When that happens extra sparks are created which also fire the injectors more often. Usually that will show up on your tachometer as erratic needle movement, excess RPM or a quivering/jumping inactive needle. Make sure that you marked the original position of the AFM vane, in case you find that the source is somewhere else. The AFM should never really need adjustment on a stock engine. -

To jonbill's point, below. And if you post a picture of a few cam lobes a guess could be made about whether it's been reground or not.

-

One "trick" to increase cam lift is to run tighter lash. But it's dangerous, if a valve doesn't close completely it can burn/warp. Another possibility is "sunken" valves. Early gasoline had lead in it which lubricated the valve seats. When the lead was removed valve seat wear increased dramatically. It's not uncommon to find sunk valves on 240Z's, as I understand things. So, could be intentional, could be valve seat wear.

-

Eibach Springs - Front sits high... *pics*

NewZed replied to PCressey's topic in Brakes, Wheels, Suspension and Chassis

They're still working as the wheel drops in to depressions or one side of the car lifts. That's how progressive rate springs work, the weaker end will collapse faster than the stronger end. The problem people have is that the rates are wrong between front and back. With PU bushings there is no lifting effect from the bushing. So, it doesn't matter when you tighten the bolts and nuts. I think it's just a bad product. I don't know why people keep buying them. That's why MSA keeps selling them, because people keep buying.- 48 replies

-

- suspension

- springs

-

(and 1 more)

Tagged with:

-

You could have a 78 car or system, or a 78 engine and the sender wasn't swapped. But the two prong sender/switches were used from 78 on in to the ZX's. Might be that you got a late 77 with a 78 system. What is the build date of your car? It should be on the plate on the door jamb. Here is the 1978 system.

-

Eibach Springs - Front sits high... *pics*

NewZed replied to PCressey's topic in Brakes, Wheels, Suspension and Chassis

This comes up so often that it might get overlooked - make sure you tighten the suspension components with the car on the ground if you loosened, removed, or replaced any bushings. The factory bushings provided some "spring" to the suspension. And, because of that, if you wanted to get tricky, you could have a heavy friend sit on the front while you tighten the bushing bolts and nuts. The bushings will help hold it down. Edit - or you could lift the back while tightening. This is only an issue, and will only work, with the factory rubber bushings.- 48 replies

-

- suspension

- springs

-

(and 1 more)

Tagged with:

-

Eibach Springs - Front sits high... *pics*

NewZed replied to PCressey's topic in Brakes, Wheels, Suspension and Chassis

The Eibach springs seem to have more problems than any of the others. They're just inconsistent. Some sit too high, some sit too low, many sit too high in the front. some too high in the back. These stories have been cropping up for years and years. MSA keeps selling them and people keep having problems. Looks like some numbers might have changed slightly but it's still Eibach and MSA. https://www.zcar.com/threads/240-too-low-w-eibach-springs.293086/ Discussion Starter • #1 • Nov 6, 2009 Just recently got my 71' back on the ground. Installed Tokico HP Struts w/ the Eibach PR Springs from MSA. The front looks good, but the rear scrubs the tires (195/70R14) on any dip or bump. I have been searching alot on this issue. Most of the time it seems the springs were reversed or upside down. It is just not the case for me. Here's the rundown: Contacted MSA to verify proper installation: They state part # 6305.001 are the front springs and 6305.002 are the rear -- I can see the numbers on the front and they match. They state shorter coils should be at the top -- they are. They state the longer spring should be in the rear -- as I remember they were. However, I found one post where someone stated the longer springs went in the front???- 48 replies

-

- suspension

- springs

-

(and 1 more)

Tagged with:

-

[72 240z] Distributor Spacer STUCK on Distributor

NewZed replied to Hindenzerg1266's topic in Ignition and Electrical

Check the vacuum advance breaker plate while it's out. The ball bearings get rusty and stick. Don't force it, the plastic bearing retainer will break. Some people don't use vacuum advance with carbs but if you do you'll want it to move freely. -

[72 240z] Distributor Spacer STUCK on Distributor

NewZed replied to Hindenzerg1266's topic in Ignition and Electrical

Mistake. -

[72 240z] Distributor Spacer STUCK on Distributor

NewZed replied to Hindenzerg1266's topic in Ignition and Electrical

Never mind. -

Rear control arm bushing orientation?

NewZed replied to fusion's topic in S30 Series - 240z, 260z, 280z

There's a whole deep discussion about that over on CZCC. https://www.classiczcars.com/forums/topic/64195-rear-control-arm-bush-alignment/?tab=comments#comment-602505 -

[72 240z] Distributor Spacer STUCK on Distributor

NewZed replied to Hindenzerg1266's topic in Ignition and Electrical

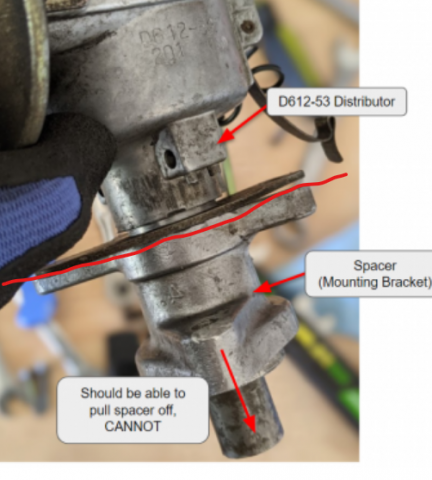

You should show a picture of your distributor, not pictures from the internet. There's something odd about what you're describing. It sounds like you haven't even pulled the distributor. If you have the pedestal mounting bolts out just pull up and the distributor will come out. It should not be complicated, at all. Most people call this the pedestal, not a "bracket". -

[72 240z] Distributor Spacer STUCK on Distributor

NewZed replied to Hindenzerg1266's topic in Ignition and Electrical

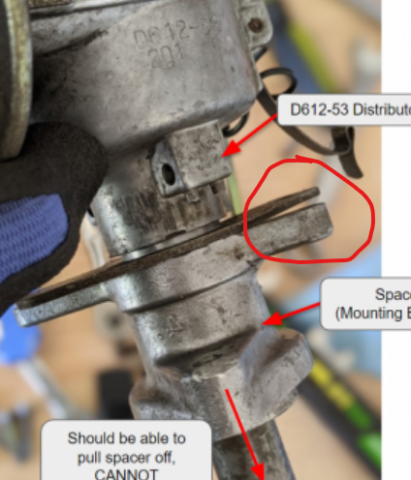

Here's another showing the plane of separation between the part that turns and the part that doesn't. -

[72 240z] Distributor Spacer STUCK on Distributor

NewZed replied to Hindenzerg1266's topic in Ignition and Electrical

You're trying to turn the wrong part. Loosen the single screw, Phillips head, holding the distributor plate to the pedestal. Then the distributor will turn. The two bolts hold the pedestal down. Those are often sealed with gasket sealer since they have oil underneath. It's not meant to turn. Here is one of your pictures with a circle showing where the screw is. It should be easy to see. -

curious to know what are the best L Series Transmission options now?

NewZed replied to primaz's topic in Drivetrain

Thanks. Never heard of them. Actually I've heard of Datsunworks. Lost track of it though. http://datsunworks.com/ https://www.godzillaraceworks.com/ https://www.godzillaraceworks.com/drivetrain -

curious to know what are the best L Series Transmission options now?

NewZed replied to primaz's topic in Drivetrain

Do you have a web site? Could put it in your sig. Don't know where to see your products. -

curious to know what are the best L Series Transmission options now?

NewZed replied to primaz's topic in Drivetrain

. -

curious to know what are the best L Series Transmission options now?

NewZed replied to primaz's topic in Drivetrain

My post was actually directed at primaz. He never really defined what he wants a different transmission for. So really it's just about options. Best for what? Sounds like mostly long term usage and maintenance, planning ahead. Good idea. Why I had three spares of various forms in my garage. Once you get deeper in to it you have to worry about ratios also.