NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Help identifying brake system

NewZed replied to Arcdef's topic in Brakes, Wheels, Suspension and Chassis

Does it have stock drums in back, and disc up front? Might be that the PO went with a different MC bore if he did some brake mods. Since the MC is not what came on the car it might be that it's already "newish". It looks new. If things work right, maybe just leave it alone. -

Help identifying brake system

NewZed replied to Arcdef's topic in Brakes, Wheels, Suspension and Chassis

Looks like you're missing the spacer/adapter also that goes between the booster and MC. https://zcardepot.com/products/brake-master-cylinder-booster-aluminum-spacer-plate-240z-260z-280z?variant=19279175647345¤cy=USD&utm_source=google&utm_medium=cpc&utm_campaign=google+shopping&gclid=CjwKCAiAyc2BBhAaEiwA44-wW3ZsP-H-fUnyxq-qimqBGJrRq33HmeIh_yfhvkh2NYyYrS1l8tYQjRoC0U8QAvD_BwE -

Help identifying brake system

NewZed replied to Arcdef's topic in Brakes, Wheels, Suspension and Chassis

This is the 280Z with the 3UZ swap? You should put your car info in a sig or just mention it every time. Looks like the PO had some skills and made a different master cylinder work. That stack of washers on the top bolt is a clue. Try to find out if the booster is correct for the car and look at 280Z master cylinders. -

Don't overlook the LSX engines. Fairly lightweight and powerful. And transmissions. That's the other spendy part about more power and different engines. And rear end. Big torque and sticky tires and you'll want more back there.

-

If you browse around you'll find that the "turbo" motor is really only different in that it uses the P90 head, which has no liners in the exhaust ports, a J pipe, and a turbo exhaust manifold. People have bolted the turbo parts on to either of the other NA engines and made them work just fine using aftermarket engine management. If you want to make 350+ HP you'll need aftermarket engine management. So, all you really need are the J pipe and the exhaust manifold from a 280ZX. There might even be aftermarket suppliers for those parts. That's how I'd break it down. Just see what you can find and started piecing things together. If you find a whole car and the price is right, why not? The rest depends on how deep you plan to go in to the engine. Too many possibilities to make a recommendation. Here's a member who has some opinions. But, if you're like most people who start a project your plans will change along the way. you just need a jump off point.

-

Here's some stuff. Still relevant, but there's newer engine management now. It came from here: https://forums.hybridz.org/forum/90-l-series/

-

And the Multi quote function.

-

It sleeps with the Edit function, apparently. And the fishes.

-

Nope, nor Edit'ing allowed. Bumer. Ioriinc.

-

Thanks Super Dan, it seems to work. Let's see if the Edit function is back. I hate to let my misspellings sit uncorrected.

-

Hey Michael I feel like I should pseudo-apologize. I am not a real moderator. One of the real ones (RTz) gave me the "clandestine" title a few years ago because I like to get involved and help solve problems. But, I don't have any real power, and your message won't reach me. But, your message should reach SuperDan and I think that he is safe with your email address. p.s. my post "what is your email address?" was directed at SuperDan, since he didn't supply it. At this point there is no way to communicate with anyone on the site except through posts on the main forums. No messaging allowed. The site is having some problems.

-

Even your own. And the Edit button is gone.

-

Clicking on anyone's avatar gives the 500 error.

-

-

What is your email address?

-

There are two levels of diagnostics. One is just measuring simple continuity the other is taking resistance measurements. The numbers are much better than the n.g. test. Anyway, one thing that could be causing your problem is a blown fuel pressure regulator. You'll only see it if you remove the vacuum hose from the FPR. Raw fuel can pass right through it in to the manifold, if it's blown.

-

big block Z, "across the centuries"

NewZed replied to Michael's topic in S30 Series - 240z, 260z, 280z

No offense, but some details on your own car would be more interesting. I've only been on the forum since 2009 and I don't remember seeing any big block Z's since then. The biggest motor I saw in a Z was BRAAP's father's Z with the Mopar 440, and that was just old pictures that he had saved. I think that you might be the last of the big motors. It's all LSX now. Many of the people building fast cars on the site now probably don't really know what a "big block" Chevy is. Some of the guys that were active in the few years after I joined visit now and then but activity has faded pretty rapidly. The site almost went extinct, SuperDan was considering shutting up shop. You'll probably have to message the names you remember if you want to get some interest back up. It's slow here now. -

5 lug front hubs using cheap off the shelf parts

NewZed replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

What's the modification? I tuned out when they showed a dog instead of a car. -

Assistance with identifying shifter?

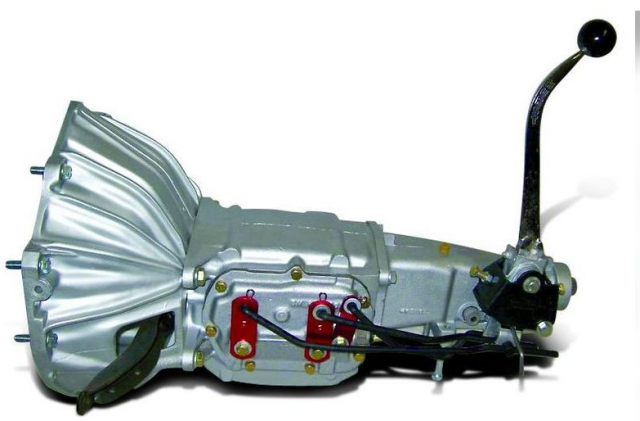

NewZed replied to Witchboard's topic in Gen I & II Chevy V8 Tech Board

You could just put it up on jack stands, under the control arms, remove the shifter, start the engine, then move the levers by hand, and listen. With no load the synchros shouldn't have a problem moving the wheels. Or you could reach through the hole while using the clutch. Or just put it in gear with the engine off and rotate it by hand, or start it. Lots of things you can do before dropping the transmission. Here's a picture, they even painted the levers red. 1-2, 3-4, and R pretty clear. It might be something as simple as the bushings in the levers. I probably got ahead of myself when I suggested it was internal. Can't really tell when you heard the grinding. Check the bushings first. Move the levers by hand and see what you can learn. It's super simple. They stick straight up in neutral and forward or backward will put it into t a gear. I don't know if the Saginaw will let you put it in two gears at the same time or not so be careful of that. When you move the shift lever left or right what you're doing is choosing just one of the levers. You can't get to the other lever unless you pass through neutral, so that keeps you out of two gears at the same time. Notice that diagram also shows you which is 1-2 and 3-4. https://www.hemmings.com/stories/article/saginaw-four-speeds -

Assistance with identifying shifter?

NewZed replied to Witchboard's topic in Gen I & II Chevy V8 Tech Board

You can disconnect the shifter and just move the levers to try the gears. There's really not much to how the external shifters work. Move one lever in to gear and the other one to neutral. Neutral is the middle spot, of three positions, for the 1-2 and 3-4 levers and reverse is just two positions, in or not. I pilled that from 40 year old brain files so it could be wrong. But that's what I remember. Looks like you are trying to set it with a screwdriver in the "adjustment" hole. That's how I remember doing my old Hurst shifter. It had a stripped thread so I had to reset it occasionally. Your description sounds more like an internal issue than a shifter problem. -

-

Do I Need Bump Stops With New KYB's?

NewZed replied to Mayolives's topic in Brakes, Wheels, Suspension and Chassis

It's a common problem. Apparently, difficult to fix, it's been reported many times over the years but nothing happens. Just copy all of the words in the other post and create a new thread. -

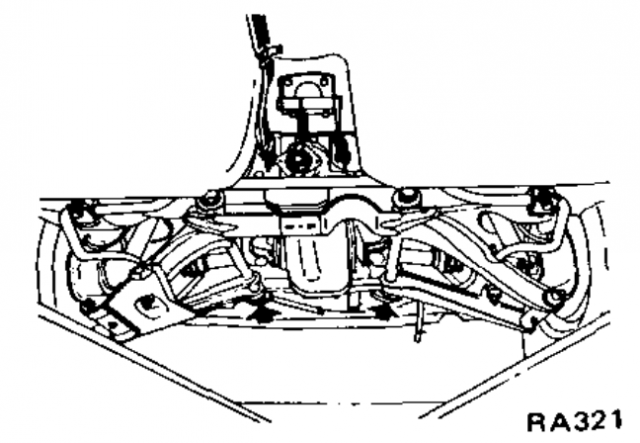

Doesn't the crossmember effectively "box" the driveline tunnel at the back of the car? Thinking that it only serves as a spot to mount the diff and to clamp the control arm bushings might lead to unintended consequences.

-

car is loose in rear end?

NewZed replied to springtimemotors.jason@gmai's topic in Brakes, Wheels, Suspension and Chassis

What would you see? There are eight bushings that could be deflecting/compressing, all rubber if they're original. Two inner and two outer on each control arm. People have found that the outer ones can completely disintegrate over time. But you have to pry on them all to find out if they're worn. There are pictures around the internet of the back wheels of Z cars moving forward by quite a bit under the force of powerful engines. The bushings are pretty thick and compress a lot. If the rear is moving to the right it seems like the left wheel is moving farther forward than the right one, pointing inward and driving the rear to the right. Just a guess. The other possibility is that the front and rear aren't on the same lines, dog-tracking. You can usually see that by eye, from the back. If the rear end is already to the right it will try to drive past the front end under acceleration. An alignment would tell you where you're starting from. But the rubber bushings weren't designed for the power you're putting through them. They're going to squish. You just need to get them to squish evenly. Seems like a good application for polyurethane bushings. Just some thoughts. -

Wrong rotors, buyer beware.

NewZed replied to Cruzzar's topic in Brakes, Wheels, Suspension and Chassis

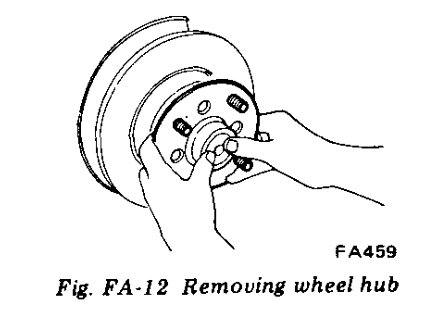

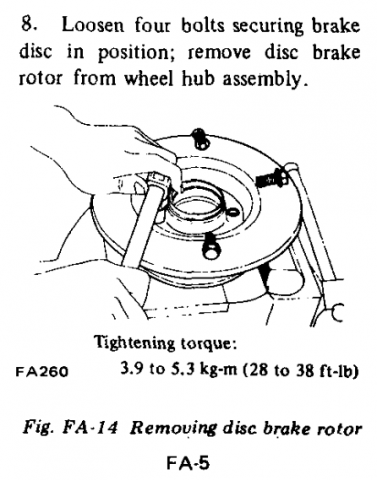

I had forgotten about that myself. Rotor bolts (not lugs) on one side and wheel lugs on the other. Seems to the source of the confusion.