NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

How can you do all of this - But not do this - It doesn't make sense.

-

The hook will come out fo the loop when the interior panel is off because the handle drops in to the door. When the panel is on, the hook will probably stay in the loop, unless something has been bent or maladjusted along the way. Put the little black pastic piece back on with the panel off and you might find that the hook stays where it should.

-

You'll spend more on gas and piss off the people driving behind you. For as long as it runs before the plugs foul.

-

I think that Nissan used Nippon or Nippon-Denso or Denso for injectors and that they are color-coded. The a46-00 is the common number that doesn't tell capacity. Beige though, would be the 188 CC NA injector, used on the 280Z engine. Stock 280Z NA injector.

-

I think that johnc started this thread with the title and Post #1 intended to draw out the fools, for entertaiment value. It's working.

-

You're a nice guy Miles. I was just trying to break even, but the middle is hard to hit. Hopefully he can take some advice without too much damage.

-

Too funny. I was also going to direct you here before - http://forums.hybridz.org/forum/68-new-members-forum/ - and suggest reading the first three threads but realized that actually did a fair job of capitalizing. But your second post is a fail on that issue. The ipad is supposed to a powerful computing machine, not like the iphone. How can your ipad not be able to download the FSM? You don't have the unzipping software, right? Try here, all you need is a pdf reader - http://www.nicoclub.com/FSM/ - you can download just the chapters that you need. So sad....

-

Go here and download the FSM - http://www.xenons30.com/reference.html Open the Clutch chapter...read. Read this thread too, just because it fits and it's so recent. It will be funny, if you're not too sensitive - http://forums.hybridz.org/topic/109702-hybridz-is-not-automotive-101/ Good luck.

-

That's the part. Looks like it even comes with new plastic for the rod clip. You should be able to reuse everything else. Hope you can make your hands tiny.

-

It was worth a shot. The FSM shows it on the side and on top also. I assume, at least, that it looks kind of like the 2nd picture.

-

When the interior panel is back on the door the inside handle won't be caught under that metal piece anymore. It will sit whre it's supposed to. Not sure why it 's hard to pull though. Your door handle is broken, as you thought, and it looks like the actuating rod has popped out of the hole it's supposed to sit in. Remove those two nuts and the handle will come out from the outside. There's a support piece on the inside and a gasket on the outside so remember where the pieces go and try not to tear the gasket, it might be painted on. You'll probably be able to maneuver the rod out with the handle. The top end of the bent rod will push out of the plastic piece in the handle, it's a snap fit, don't try to remove the plastic piece with the rod in it. Get another handle and you'll see what a good one looks like. Install the new handle then install the actuating rod, I don't think the rod will go where it's supposed to go when the handle is unbroken so you can't reinstall it fromthe outside with the rod attached. At least it wouldn't on my car. Bolt the new handle on, set the white adjustable end of the rod in it's hole, then use some long pliers or really strong fingers, with some WD40 or something to push the rod back in to the upper plastic clip on the handle. Then adjust the white nut up or down until you like the feel of how the door opens. You might need to add some goop or tape afterward to hold it in place so it doesn't walk out of adjustment during use. Good luck finding a handle, I think new ones are available out there somewhere. I got mine at a wrecking yard. Edit - writing while cg posted. Two for broken...

-

I see that this your first post. You might want to read this thread before feelings are hurt - http://forums.hybridz.org/topic/109702-hybridz-is-not-automotive-101/

-

Just curious - did you look before my post or after? Wondering if I'm really that good at figuring out what a drawing is showing, and if I added any value...

-

Have you looked at the bottom of the intake manifold? I've never seen one but that's where I'd look. Based on the drawing.

-

-

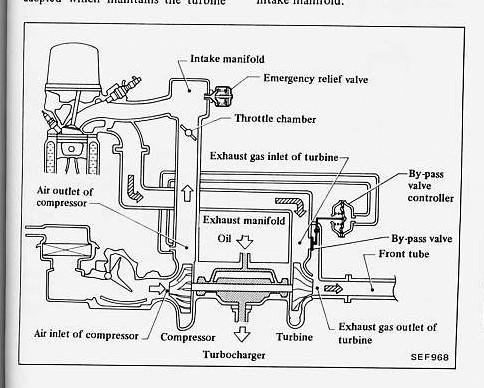

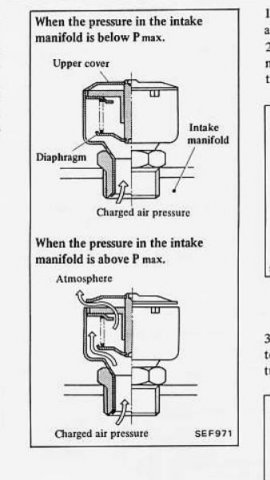

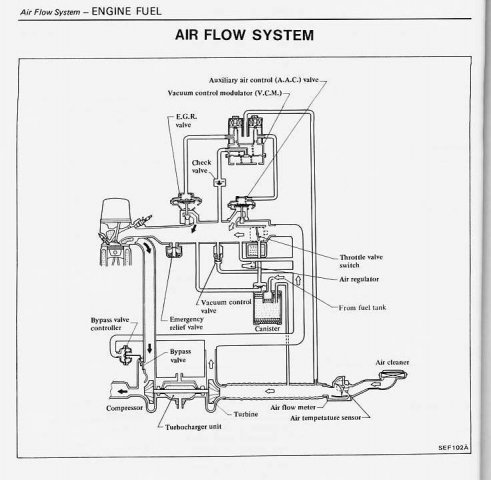

Read the Emissions (describes the PCV system) and Engine Fuel (describes how the EFI system works) chapters of the appropriate FSM. There are diagrams and descriptions of function. You'll be ahead later also when you're trying to get the engine running. Search the whole internet using Google and you'll see what PCV systems are for. They're actually good for an engine.

-

Could it be transferred brass? The dog teeth look pretty rounded anyway, don't they. The brokevw link had some good focus on the "sync keys", or "inserts" as Nissan calls them, and the springs underneath. I don't think that people pay much attention to them since they're small and it's not obvious what they do. There's a Hybridz post out there by HizandHerz about doing some work on the "baulk springs". I assume that he means the insert springs. You might have seen it already since he also mentioned lapping the synchro surfaces. http://forums.hybridz.org/index.php/topic/58315-280zx-rough-shiftinghelp/page__p__537658__hl__synchro__fromsearch__1?do=findComment&comment=537658

-

Leaking from body plugs under pass. side

NewZed replied to str8pipez's topic in S30 Series - 240z, 260z, 280z

Look at the other side of the plug. It's under the carpet. Probably aniifreeze from a leaky heater core or hoses. -

The coil needs to have current flowing through it to work. It fires when the current is interrupted. You can have voltage but no current flow. Follow the circuit from the power supply, through the coil, and to wherever the circuit making and breaking hardware is (BIP373 probably, inyour case). The ignitor would do that job in the stock system, at the control of the ECU. The BIP373 transistor in MS should be doing that job now. If it's connected correctly, then the next thing to look at would be the signal that the ECU uses to control BIP373, probably the CAS. Power+ > coil + > coil windings > coil - > BIP337 > ground BIP337 grounds the circuit when the ECU controls it to do so.

-

I "Like"'d your post and got the message below, even though I've never Like'd anyhting before, let alone today. Apparently my positivity quota is zero, which is good since it's easy to achieve. But I only did it to see what would happen. What is supposed to happen? Is it like a contest, where you write your post with the goal of getting Like'ed? Like a LIKE ME video game? Is it a self-esteem enhancer? I don't get it. An error occurredYou have reached your quota of positive votes for the day

-

possible jammed injectors.

NewZed replied to Metric Killerz's topic in Trouble Shooting / General Engine

TD, he said that he put the stock regulator back on, in his Post #1 text-device based word dump (it's sad that I barely care about the crappy grammar and formatting anymore). The adjustable FPR was an attempt to "stop his fuel pump from shutting off" (the other problem). Two vey basic things to do would be to check for spark while cranking the engine over, and to measure the fuel pressure. If one of those is missing, it needs fixing. If you have both of those, then flooding is a likely problem, assuming that no plug wires have been removed and replaced, or something unusual has happened (did you move or remomve the distributor while working onthe FPR?). If you've removed and replaced the plug wires while you were working on the FPR, make sure they're not in reverse firing order. The engine will run like you described with them backward. -

possible jammed injectors.

NewZed replied to Metric Killerz's topic in Trouble Shooting / General Engine

If you can get it started again watch the tachometer needle. When the ignition module goes bad it typically causes the tach to read high and the needle to jump all over the place, much faster than actual engine speed. I know you can link to youtube or add embed code. Don't know if the site hosts the files, probably not. Easiest to youtube it and link it. -

possible jammed injectors.

NewZed replied to Metric Killerz's topic in Trouble Shooting / General Engine

Sounds more like ignition, maybe the ignition module or just the distributor cap and/or rotor, wires, magnetic pickup coil maybe, etc. Could be any of those, but your description is a lot like how my 76 ignition module went bad. It would do what yours is doing after a run up above 3,000 RPM, but would fix itself with a restart. Edit - forgot to say that "fuel pump shutting off" might not be happening, and it's really ignition module shutting down. Another sign. The injectors rarely get stuck, expecailly if they're used regularly. If they do stick, it's usually a small leak, not a big hairy one that would give your symptoms and not all of them at once. One thing, also rare, that might hold the injectors open though, is a bad ECU. Try banging on it and see what happens.