NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Is the edge of the bushing tapered? How will you get it started? It will be interesting to see how the spindle pin fits through the compressed hole after it's installed. Does the pin fit the hole when the bushing is out? Don't overlook that many of the bushings have polyurethane replacement options just because they can. Not necessarily because they're better. The rubber that's in the original bushing is very thin and probably sees little deflection under use. The thicker PU bushing might even deflect more than stock rubber under load. Less metal, more elastic material with PU.

-

Modified STI swap or r180 w/ quaife with CV axles

NewZed replied to BluDestiny's topic in Drivetrain

So is it a clutch or a helical? How about a picture? I noticed above that you said you turned one axle and the other side turned the opposite way. They should both turn the same way, in a properly working LSD. I think if they don't that means there's no preload on the clutches or the friction surface for a helical. So, if it's a helical I think that it needs new preload devices, whatever they are in the Subaru helical or new clutch discs if it's a clutch LSD. The typical helical uses Belleville washers for preload and they wear out sometimes. I'm not a diff expert so I might be mixing somethings up. But if you post a few pictures others can tell you what you have and what might be wrong with it. There are many different mechanisms involved in LSD designs, from the way the force is transmitted to the axles, to the way preload is applied, and how much. Anyway, it's an interesting problem. It will be a real bummer if just leave people hanging and install an OSGiken without figuring out what you have and how it works. We're all here for entertainment too, you know. p.s. I tried to find a description of the Subaru Suretrac and all I can find is Eaton's page. Eaton shows a clutch LSD in their video. Can't believe how hard it is to find info on these things even though the cars are everywhere. Just weird. http://videos.eaton.com/detail/videos/differentials/video/4750907910001/suretrac-differential-operation?autoStart=true -

Modified STI swap or r180 w/ quaife with CV axles

NewZed replied to BluDestiny's topic in Drivetrain

Are you doing your own alignments or has it been done professionally? Might be that your car is "dog-tracking", as they say, and the twitch is due to that. Or you do have a loose component but just haven't found it yet. https://www.popularmechanics.com/cars/how-to/a111/1272576/#:~:text=This condition is commonly referred,perpendicular to the rear axle. -

Modified STI swap or r180 w/ quaife with CV axles

NewZed replied to BluDestiny's topic in Drivetrain

There's a clutch for each side. They wear. Draining the oil would be the quick easy way to learn more. Take the cover off and see what's going on in there. Check the oil for flakes or fragments. Might be able to pull the clutch packs without pulling the diff. It's possible on Fords, for example. There's other things that can happen like the pinion shaft working its way free. Not sure how Subaru holds theirs in place. Surprising how little there is on the interweb about these diffs. All kinds of Datsun/Nisan stuff. Probably the same as Nissan, but I've not taken one apart. Ford has a bolt that works its way loose at times. Probably want to find that out before it makes its way free. p.s. I've seen threads about other cars where people wondered for many miles about a diff noise then finally opened it up to find carnage. If it's not acting right best to open it up and look before it gets really bad. I shot a pinion shaft through a diff cover when I was a high school kid. Couldn't take the time to figure out why the car took tight corners weirdly. It went straight just fine, and it was a weekend night. -

Modified STI swap or r180 w/ quaife with CV axles

NewZed replied to BluDestiny's topic in Drivetrain

Any chance your rear tires are of different diameter? I had that happen once on a Pathfinder with a VLSD. Took a while to figure out. On clutch LSD's there's a clutch pack for each axle. Maybe you just need new clutch discs,as Seattlejester says. Don't know where to get them. https://www.rallispec.com/dif_ohk_sti_t.html -

You should call them as stated above. They might not know. They sell a lot of parts.

-

https://www.thezstore.com/page/TZS/PROD/23-4137

-

You should be on classiczcars.com, where they restore cars. Hybridz people tear them up and rebuild them.

-

It's there. Wisconsin uses a different department to track their businesses. Looks like he had some issues but got things squared away June of this year. In good standing as of then. That's a good sign, I'd guess. Probably just backlogged. Finding help with the virus happening is probably difficult too. From one perspective you can't blame him for trying to be hidden. The internet is full of problems. On the other hand, exposure is part of being a business owner. Were I one of you I'd send him a polite Facebook message on his personal page, if I had sent him some money and wasn't getting a response.

-

You might be fine, along with everyone else. It's just an example. Try the guy's personal Facebook page. That would be fair. It's linked on the business page, above. Team Member.

-

It's odd but their Google search results show "LLC" meaning that they should be registered in a state somewhere as a limited liability corporation. A legal entity, allowed to do business, pay employees, pay taxes, etc. But on their Facebook page and their actual web site they don't show that at all. Also no location or phone numbers. So, they, or he, could disappear overnight and it would be difficult to find him/them to pursue reimbursement. (See Senza Pari, for example). Enthusiastic people with ideas crop up all the time then get bogged down in the actual work of running a business. Be careful with your purchases. Get that critical information before you send your money. I only realized this about Apex Engineered because I just wanted to see what this "company' was about. Kind of worrisome. If you know what state he/they work(s) in the business should show up on the states Secretary of State LLC page. I added the link for Washington state as an example. Contact information will be there. You can also check the Better Business Bureau to see if they're having problems. Might be a great guy, great company, but maintaining a business as a "going concern" is a lot of work. Kind of just using this company as an example, I don't know anything about them/him. The signs are there though. Good luck people. https://www.sos.wa.gov/corps/limitedliabilitycompaniesllconlineandpaperregistrations.aspx https://www.google.com/search?rlz=1C1SQJL_enUS862US862&sxsrf=ALeKk02hq2KeDj5c7JU6_jungnyo3ujx1Q%3A1598309256492&ei=iENEX4POHcfk-gShg7PwAQ&q=apex+engineered+llc&oq=apex+engineered+llc&gs_lcp=CgZwc3ktYWIQAzIGCAAQFhAeMgYIABAWEB46BAgAEEdQipUFWKeYBWDlmgVoAHACeACAAVuIAfEBkgEBM5gBAKABAaoBB2d3cy13aXrAAQE&sclient=psy-ab&ved=0ahUKEwiDsuX79bTrAhVHsp4KHaHBDB4Q4dUDCAw&uact=5 https://www.apexengineered.com/contact-us.html https://www.facebook.com/pg/apexengineered/about/?ref=page_internal https://www.facebook.com/ohm.pandya.5 https://www.bbb.org/

-

That hole is not open to the inside of the engine. It's dry, as you reminded. You could even drill out the remnants and rethread it. Just don't drill too deep.

-

Help diagnosing large amounts of white smoke coming out the exhaust

NewZed replied to jjslade's topic in Nissan L6 Forum

The type of gauge and any adapters or extensions can cause low pressures. The extensions add volume to the combustion chamber. What are you using? The numbers are all very close, which is important. You'll get more ideas if you answer all of the questions that have been asked. There's not much in what you've written that tells much. Idles poorly, white smoke, low cylinder pressures. Just not enough there to even make a good guess. -

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Just curious - who's Vlad? -

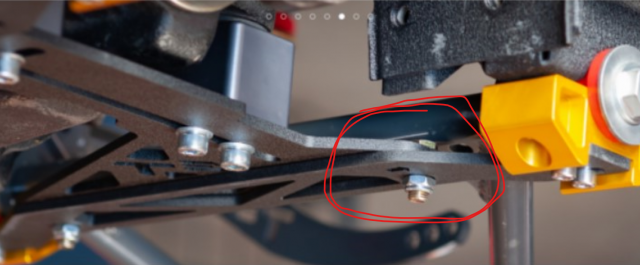

Oops, I forgot about that. Dry. Even better, finger tight would probably have worked. Too late though. It's not a strong metal, as shown by the fact that it broke. Might be that you're only contacting the insert inside the threaded portion, circled in red below, and that's what's spinning. Your EZ Out is not contacting the thread outer sleeve. Find a way to make contact with the outer sleeve that has the threads. Maybe a chisel to poke/peel the inner portion inward, jam it in between the insert and the threaded sleeve. Even a pick or a thin screwdriver might jam in to the gap there.Just a guess. Without the head on it there's really no tension on the threaded portion. It should be finger tight, unless you used thread locker on it.

-

Seems like it's just waiting for the right size screw extractor, AKA EZ-out. Take the broken one that you have to the hardware store and find the one that fits. How tight were trying to get it? It only needs to be tight enough to keep the fluid from leaking. https://www.google.com/search?rlz=1C1SQJL_enUS862US862&sxsrf=ALeKk03sxj-QUSEnC0E3c1GDEwJVOJlsRQ%3A1597778847396&ei=nys8X9LVF8Kw0PEP9LauoAw&q=ez+out&oq=ez+out&gs_lcp=CgZwc3ktYWIQAzICCAAyBAgAEEMyAggAMgQIABBDMgIIADICCAAyBAgAEEMyAggAMgIIADICCAA6BAgjECc6CggAELEDEIMBEEM6BQgAELEDOggIABCxAxCDAToICC4QsQMQgwE6CAguEMcBEKMCOggILhDHARCvAVCGK1j6NmDkOWgAcAB4AIABbYgBrgSSAQM0LjKYAQCgAQGqAQdnd3Mtd2l6wAEB&sclient=psy-ab&ved=0ahUKEwiSoYOFvqXrAhVCGDQIHXSbC8QQ4dUDCAw&uact=5

-

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

This guy does a god job of keeping up with Z car options. https://zcardepot.com/collections/drive-shaft -

VISE-GRIPS

-

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

The 1975 280Z propeller shaft and R200 is the one with the odd bolt pattern and bolt sizes. Avoid 1975. And the Z31 has its own bolt pattern also, as you recalled. I think that the 240 shaft itself might be of smaller diameter than a 280Z shaft. But the 240Z shafts have replaceable u-joints so it's easier to do a yoke swap, if you find a yoke with internal clips. The 280Z shafts take extra machine work to get that done since they have staked u-joints. I think that the 260Z might also have staked joints. And, of course, the early 240Z's with the forward mounted diffs have the 1 1/2" shorter propeller shafts. Lots of ways to get stuck. -

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

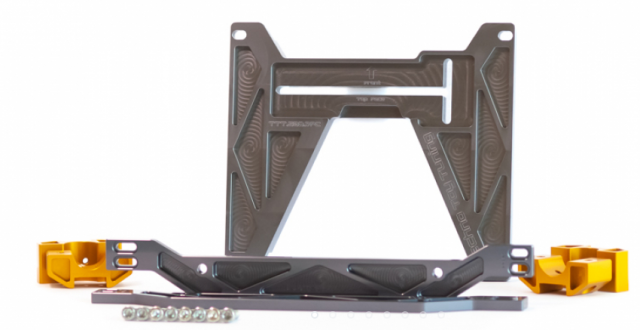

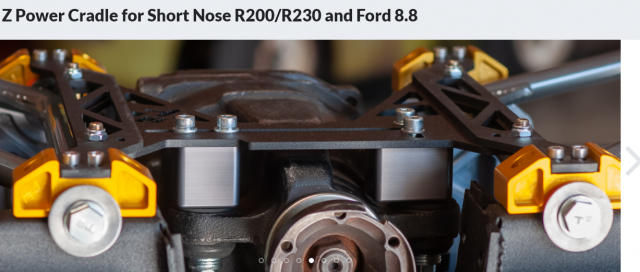

Who knows. The parts have a lot of flash to them, they look nice, but no results posted or shown. Just words, saying that it's stronger. A little story about the 10 second Z car that used them would be neat. A video would be cool. Why does he sell aluminum and steel but just show the steel parts mounted? Edit - I guess he shows both. Just an odd assortment of upside down pictures. Hard to tell what's going on. Questions... If the bushings are clamped down with metal contact at the bolt and the nut the noise will transmit through the metal. Hard to tell. Hopefully somebody will try one and see what happens. I'm just an internet critic. -

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

On the edges, but they thinned it out for some reason. Weight savings? Still a lot of leverage on those outer mounting points. Why didn't he CNC it all of one piece? And look at how little material there is around the outer mounting bolts. You can easily imagine that whole plate tearing right off of those four outer bolts. Hard to stop once you get going. It's just not "substantial" enough. And, last "pick" - it looks like a solid mount. So it's going to be noisy. Easier to visualize the diff nose lifting with the picture right side up. -

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

It is just four small bolts under tension pulling on a thin plate of aluminum, isn't it? And kind of "levery" on the outboard mounting points. You can almost see the metal fatiguing around those outer bolts. The concept seems to have potential. It's essentially a variation of the Arisona Z Car setup, that doesn't seem to be available anymore. Which is essentially a variation of the welded cradle in your big thread. So close... -

I can smell the mice just looking at that picture. Good luck. Check out the current rear end discussion.

-

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

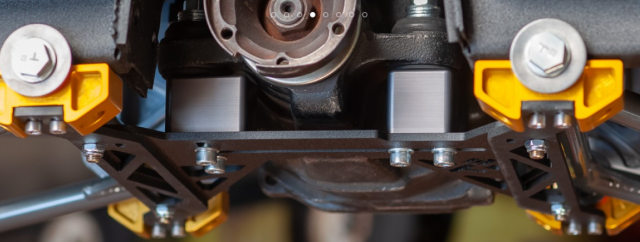

T3 seems to have two different mounts available. The old "bad" kind and a new one. https://technotoytuning.com/nissan/240z/complete-r200-short-nose-r230-rear-end-conversion-z-car https://technotoytuning.com/nissan/240z/z-power-cradle-short-nose-r200r230-and-ford-88 -

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z