NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

The later ZX's matched the 3.062 1st with the 3.9. The 280Z 5 speed cars and early ZX's, used a 3.321 and a 3.54 rear. Your 75 4 speed would have a 3.54. 79 ZX's have a wide range of diff ratios, based on the model and the transmission. Everything from 3.36 to 3.9. 79 is an odd year for options. Good luck. Don't forget the funky diff pattern on your 75.

-

Compare 1st gear ratios also, to see if 1st gear will even be usable. Also, 1975 has an odd flange bolt size and pattern on the diff and propeller shaft. So, if you get a different diff you'll need the propeller shaft flange also. And the 240SX is not a direct swap, in case you didn't know. http://zhome.com/ZCMnL/tech/240SX5spd/transmission.htm

-

A musician's therapist (The $300 Z)

NewZed replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

I'm not aware of any "bolt-in" CV axle swaps. They all require welding or hub axle and flange swaps. Plus the fact that most CV axles are too long unless you go with the Porsche 930 style. Which also, apparently, have their own issues of being loose themselves, after wearing out quickly. There might be new stuff out there. But the CV swap problems and adventures have been a constant source of entertainment over the years. No offense to those with the problems (but thanks for the stories). Good luck. Hope it's just u-joints. Get high quality u-joints, the cheap ones can be already loose. Datsun u-joints are surprisingly tight, with their precision thickness retaining clips and everything. There are six total, of course, in the drive train. So any looseness adds up. -

A musician's therapist (The $300 Z)

NewZed replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Have you checked them, by eye, while prying on them? Noise during shifting could be a lot of things. p.s. "going CV" isn't as easy as it sounds. Expensive too. -

mystery rear main seals included with new round seal

NewZed replied to Mayolives's topic in Trouble Shooting / General Engine

The pictures are gone but you can get an idea of what's possible. -

Wouldn't these guys know? There aren't that many variations. https://www.rhdjapan.com/contacts/

-

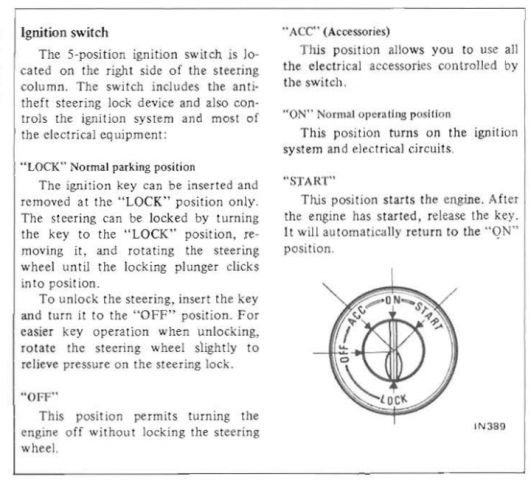

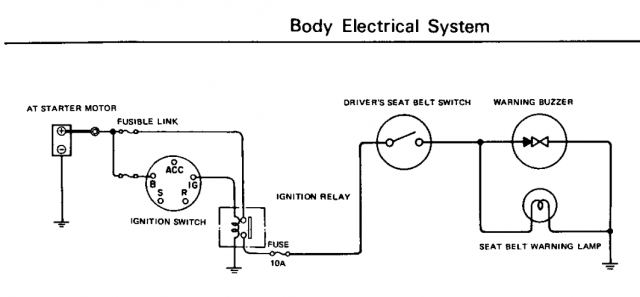

Ignition wire (BW) shows 12v in "LOCK"

NewZed replied to ukcats07's topic in Ignition and Electrical

Actually, that fills out the thread. I was looking for a good image of that but didn't find one. You can see what should have power (continuity from the B terminal) at each position and test those. p.s.I think that the R, IG, S, B, and A are molded or printed on the back of the switch. -

I'd try to sell them to Dave at ArizonaZcar. He builds strokers. I think he grinds his own but might be interested. DatsunSpirit also. http://datsunspirit.net/spl-series/ http://www.arizonazcar.com/index.html http://www.arizonazcar.com/about.html

-

Ignition wire (BW) shows 12v in "LOCK"

NewZed replied to ukcats07's topic in Ignition and Electrical

-

Ignition wire (BW) shows 12v in "LOCK"

NewZed replied to ukcats07's topic in Ignition and Electrical

Disassemble the electrical switch from the mechanical portion and see if it works correctly. Maybe the electrical portion is over-rotating. You're describing two things happening that can't both be correct. The swatch tested "good", but it allowed power through at Lock. Here's the 5 contact diagram from 1976. -

Ignition wire (BW) shows 12v in "LOCK"

NewZed replied to ukcats07's topic in Ignition and Electrical

You described a whole bunch of stuff. It's not clear where on the "B/W" wire you measured. And there's a lot of B/W wires in the car. If you're not getting power through the switch with the key in the Lock position then the power on the B/W wire is coming from a short or some other weird wiring thing. You said it all tested "good" which means that there was no continuity from the power wire through the switch with the key at Lock. Disconnect the switch entirely and put it all back together. If you still get power on the B/W wire then the Lock position on the switch is irrelevant. Forget about the switch and keep searching. -

Ignition wire (BW) shows 12v in "LOCK"

NewZed replied to ukcats07's topic in Ignition and Electrical

Check the wires at the back of the ignition switch. There's only four. Sounds like the electrical portion of the switch is worn out and shorting. You can get replacements. There's a screw that you have to drill or cut the head off of. Anti-theft measure. -

Interest in Chassis Strengthening Kits

NewZed replied to sabiauto's topic in Brakes, Wheels, Suspension and Chassis

People will probably compare what you're offering to the typical piece by piece mods that are done, on the way up to a cage. Here is a thread that covers much of those mods. Might get more response if you break your package up in to sub-kits. More affordable and people can choose between the curvy stuff and the straight line power stuff. https://forums.hybridz.org/topic/49036-suspension-modification-faq/ -

Robbo got a response from Ohm through personal Facebook, 8/26 apparently, thread linked above. Might be worth a shot. Maybe point him to this thread, so he can explain. If he's buried with work he might not really be aware of how bad things look, at least on this forum.

-

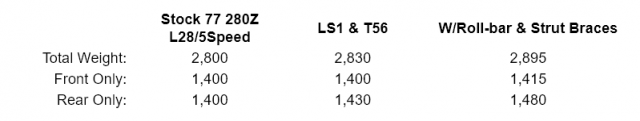

Aluminum Block vs Iron Block

NewZed replied to lotussutol's topic in Gen III & IV Chevy V8Z Tech Board

Here's some Z numbers, for aluminum. The transmission comes in to play also. http://www.brokenkitty.com/zcar/zcar.htm -

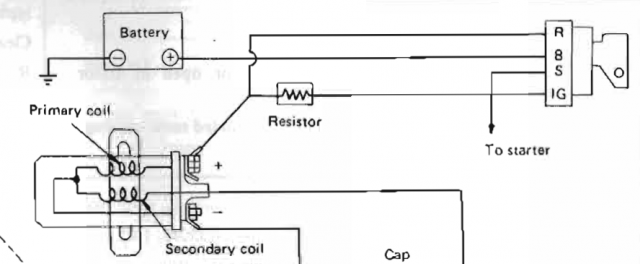

Can't tell if you tried all of the different options after it finally quit starting or after the starting, running, then dying. But the starting, running, then dying suggests that something is overheating. Coils can overheat and go open circuit, and I think that the MSD boxes put more load on the coil with the multiple sparks. Anyway, try a new coil. I didn't see that in your list. Edit - actually, use a meter and check the coil's properties if you have one. But, even then, it might be overheating as soon as it sees current. A coil swap is probably worthwhile.

-

Might as well tie these threads together.

-

WTB: Modern Motorsport brace for R200 finned cover (or equivalen)

NewZed replied to 24OZ's topic in Parts Wanted

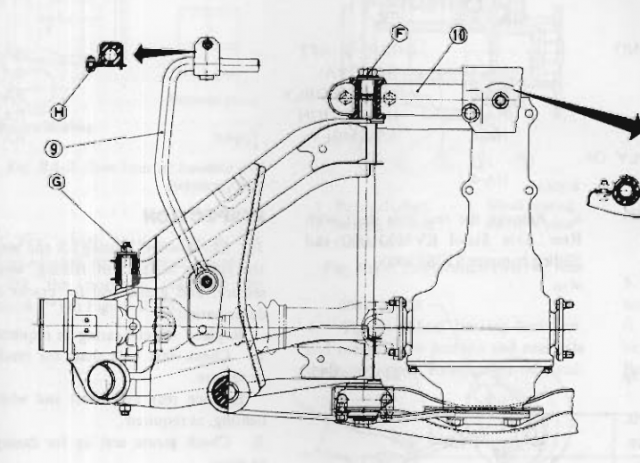

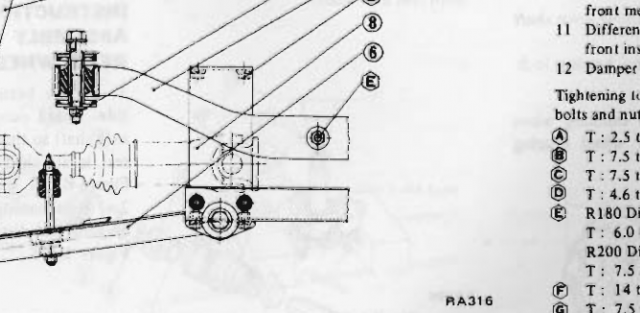

Thanks. Can you explain how the flat T3 bar sits farther back than the factory dog bone? Can't tell from the pictures. You didn't shave any fins? The cover fins are as they were on the turbo or 240SX? Just trying to understand. It's not clear, from one picture. You can see from the drawings that a straight line across those control arm brackets bisects where the fins would be. Unless there's no fins higher up. This is one of those situations where if the companies would just show their parts fully installed they'd probably make more sales. Why show half of an assembly. -

WTB: Modern Motorsport brace for R200 finned cover (or equivalen)

NewZed replied to 24OZ's topic in Parts Wanted

Doesn't look like it clears the fins of the diff cover. That's what the OP is looking for. The T3 post shows a lot of parts that aren't actually part of what he's selling. Not sure exactly what he's trying to say. The gold "dog bone" replacement is flat isn't it? How will it clear the fins? -

WTB: Modern Motorsport brace for R200 finned cover (or equivalen)

NewZed replied to 24OZ's topic in Parts Wanted

Where did you get that picture? Not sure that's all you need. This guy might still be out there. -

I just responded to a new guy's thread and he responded back. Now the whole thread has disappeared like it never existed. His name was Hobert. What happened? p.s. And what happened to the Member list? Every site has a member list. Hybridz used to. Where is it? And #2 - this Edit box does not have a Post or Save button on it. Just Edit Topic, which is the button I already pushed. Things are falling apart... Edit #2 - clicking Edit Topic saves the Edit. But that's not grammatically correct. Editing an Edit. Could somebody get in to it and make things right?

-

I did all of the bushings except that one. As I said earlier I couldn't find a reason to replace the rubber ones that were still in good shape on my car. The problem with making the bushing easy to install by removing the sleeve is that it will be looser than if you stuff it in to the old sleeve. As ZTherapy implies that bushing sees a lot of force. Under power it gets compressed and twisted allowing the wheel to toe in as it tries to push the car. And since the urethane is not bonded to the steel like the rubber is it might slip and move even more. There is a lot of hype in all aftermarket parts. It's the nature of the business, convincing people that what they have isn't good enough. I have no idea what the guy who designed that bushing was thinking. I'm just pointing out that the way that everyone has been doing it is counter to the instructions, and that it gives a bushing that is looser than if it done the way they describe it should be done. I guess that is the devil's advocate's role. I agree that it's ridiculous for them to just keep saying the words when it would be so easy to just show how it's done. https://prothane.com/about/

-

The video should be on MSA or Prothane's site. Not ZTherapy's. And why do you have to buy the video? Why would the guys at ZTherpay be experts on installing Prothane bushings? The video is about "Hyperthane" from Energy Suspension. I'll bet they just show a guy burning and hack-sawing. p.s. I'm not really arguing about anything. I just find it really amusing when companies make it difficult to use the parts they sell. It's not rational. Frustrated customers are not good.

-

"Buy" a video from a carburetor rebuilder to learn how to install aftermarket suspension bushings? Seems wrong...

-

Just because many people did it that way does not mean that that is what Prothane intended. The material is elastic so will compress to fit in to the old sleeve. What's really needed here is the guy that designed the bushing. Maybe he's still out there somewhere. As far as MSA goes, I think that they are just passing on what Prothane told them, or even just what the written instructions say.