NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

No, a real mod gave me that title because I get involved a lot. It's been a while. Not a mod. Can't move stuff. You'll probably find something. These old tachs are getting crusty, stuck needles is pretty common.

-

It should go back to zero. If it doesn't it's a mechanical problem, not electrical, probably just a gummed up mechanism. You don't want to mess with the adjustments, they haven't moved. Why post a tachometer problem in the V8 Tech board section?

-

Good stuff on the internet. Seems like generally the problem with these modifications is that the parts that they use to grip weren't designed to grip. They just create a way to jam the diff locked using parts that aren't supposed to be jammed. If the design was good the auto makers would use it. Fewer parts is cheaper and auto makers are all about making parts cheaper. https://grassrootsmotorsports.com/forum/grm/opinions-wanted-on-this-lsd-conversion/142829/page1/

-

Here's what they look like. If that helps. https://www.ebay.com/itm/3-PCS-FRONT-MOTOR-AUTO-TRANS-MOUNT-For-1972-Ford-PINTO-2-0L-3SPD-4SPD/152593939774?fits=Model%3APinto|Make%3AFord&epid=10003659700&hash=item23874ebd3e:g:0B0AAOSwFJBZScyo

-

Got a link to the video?

-

This is a bad reason to try to get to 9,000 RPM. Not logical. Buy a kit that is most optimal at 5,500 RPM.

-

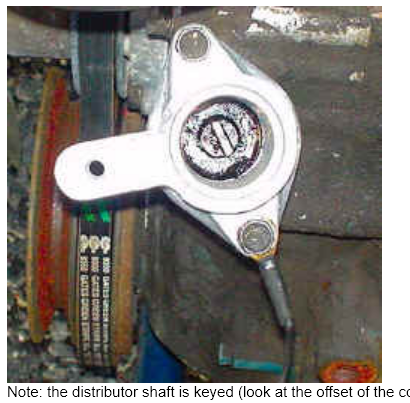

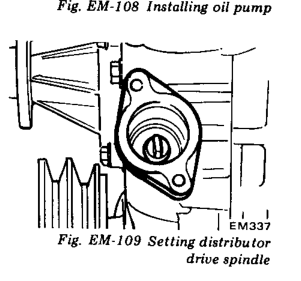

Did you swap the pedestal also when you installed the 280Z distributor? The Z and ZX use a different pedestal and they're oriented differently. Take the adjustment screw completely out so that you can rotate the distributor as far as you need. See if that gets your timing right, then see if you can move your plug wires to get there. It might be that somebody adjusted the old distributor to work with an oil pump drive gear that was off a tooth. Now that you have stock distributors it's not "right" anymore. Set the timing mark on zero on the compression stroke and see if the half moon is in the right spot in the distributor hole. Here's some pictures, the first one is not quite right but shows the size difference more clearly. https://www.atlanticz.ca/zclub/techtips/distributor/index.html

-

Stainless steel brake line problem

NewZed replied to RDuff's topic in Brakes, Wheels, Suspension and Chassis

Have you taken a good closeup look at the sealing surfaces? Use bright light and a magnifying glass. There's probably a clue there. You got single or double but they're both just a cone that sits on a cone. You can even put a final finish on the surfaces with abrasives. Look for cracks, imperfections, or crud on the sealing surfaces. -

Modern motor sports brake question

NewZed replied to Datsunfsu's topic in Brakes, Wheels, Suspension and Chassis

-

Very nice. Your other post says 72 240Z. Is the engine the original L24, modified, or is it an L28ET swap? Stock drivetrain, R180, or also modded? That's a lot of torque for the R180. Must be the Sniper or Terminator engine management, right? There's several. https://www.holley.com/brands/holley_efi/

-

They are about impossible to find. If you're using Megasquirt and hoping to use the L28ET distributor with it you're probably better off to use a different ignition triggering system.

-

Some of what you need might be here - https://www.diyautotune.com/support/tech/install/nissan-datsun/megasquirt-your-280zx-turbo/ A couple more links on the left of the page.

-

Just saw jonbill's reply. This is just a follow-on, below, that I was writing. Seems like an interesting motor. The other thing people like about the P90 is that it has the square exhaust ports without liners. The block has probably been bored or modified to allow the bigger valves to miss the sides of the cylinder wall. And there is a very common Timesert modification that people do to get rid of the hydraulic pivots. They're not actually "lifters". The P90 with flat top pistons would be similar to a ZX engine except that the swept volume would be less if it hasn't been bored much and still has the L24 crankshaft. Probably about 8:1, but hard to say for sure. Check the bottom of the P90A letters to see if the head has been shaved. That would up the CR somewhat. There are engine calculators out there too that you can play with.

-

Fuel Pump Only Gets Voltage When Car is Running

NewZed replied to munkey_mike's topic in S30 Series - 240z, 260z, 280z

-

Was Working...now no spark and ballast resistor hot

NewZed replied to goob_os101's topic in Ignition and Electrical

The coil and resistor would be getting hot because they have current flowing through them. That would be because there is a short circuit on the wiring after the coil negative terminal. Looking at all of those exposed connections, that would not be a surprise. If you can't find the bare wire or connector that is shorting to ground, your ignition module might be bad. That spade end is just connected to ground. There's a wire that needs a ground somewhere. -

Opinions on advancing stock cam timing by 4 degrees

NewZed replied to Coelocanth81's topic in Nissan L6 Forum

It will move your torque peak to lower RPM which is probably good, for an old engine. It makes the engine feel more powerful since most people don't use the high end of the rev range of their engines. Tony D has written some stories about using it as a tuning tool. There's room for the valves, the engine interference range is not that close for a stock cam. Here's a more "official" writeup about it - https://help.summitracing.com/app/answers/detail/a_id/4706/~/advancing-%2F-retarding-a-camshaft -

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

https://forums.hybridz.org/topic/88099-obx-differential-inspection-and-installation/#comments -

Settling on two rear end options...

NewZed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

https://www.google.com/search?sxsrf=ALeKk007mZ1L5AQH5KaoBHYK4COKl1lcbg%3A1602353719894&source=hp&ei=N_qBX96PM56x0PEP_8WjsAE&q=site%3Ahybridz.org+obx+and+belleville&oq=site%3Ahybridz.org+obx+and+belleville&gs_lcp=CgZwc3ktYWIQAzoECCMQJzoECC4QJzoFCAAQkQI6AgguOggILhDHARCjAjoICAAQsQMQgwE6BQgAELEDOggIABDJAxCRAjoICC4QxwEQrwE6CwguELEDEMcBEKMCOggIABCxAxDJAzoFCC4QsQM6AggAOgcIABCxAxAKUNwOWPhNYK1WaABwAHgAgAFniAG9CZIBBDE3LjGYAQCgAQGgAQKqAQdnd3Mtd2l6&sclient=psy-ab&ved=0ahUKEwieh5ri0KrsAhWeGDQIHf_iCBYQ4dUDCAk&uact=5 -

Squirt the fluid directly in to the intake manifold. If the AFM vane is not opening the fluid won't get through. You might just have a big vacuum leak somewhere. Moving the AFM won't help that. Edit - actually it might, but still... Don't forget to look for rags or mice nests in the J-pipe if you got the parts from a car that has been sitting.

-

There's a couple of long threads on classiczcars.com about how the new aftermarket fuel pumps are bad right out of the box. Poor seals. They don't pump well and they don't seal when they're off. Which pump did you get? It's a problem and there doesn't seem to be a brand that is guaranteed to work. Classiczcars is down right now but when it comes back I'll see if I can find a link. One of the guys really went deep in to the guts of the pumps and has found solutions. zKars, I think.

-

Run through the typical NA EFI checks. Could be a fusible link, or even a ground problem. Voltage and grounds are the key. Here's a reference from your past. It ran before, so it should run again. Good luck. Try starting fluid if you just want to hear it for a short burst. That will confirm spark and timing, then you can focus on the injector power and control.

-

You are way behind the curve on this swap. There is a ton of information about it on the site. The NA EFI system is set up for NA injectors. Turbo injectors will squirt too much fuel. Good luck. https://forums.hybridz.org/forum/94-engine-components/ https://forums.hybridz.org/topic/50208-the-ultimate-l28et-guidewhat-you-need-for-350whp/ https://forums.hybridz.org/topic/38461-240z-260z-280z-turbo-swap-guide/ https://forums.hybridz.org/topic/95316-braaps-l6-efi-induction-advice-and-tips/

-

Have you checked the spark plugs? Might be flooding. The turbo injectors are 265 CC, the NA are 188 CC. You're dumping 40% more fuel in than the engine needs.

-

-

It's not the R200 itself. It's the 1975 model R200. I think that 1975 was the first year for the R200, for the Z cars for sure, and for some reason Nissan changed the pinion flange pattern the very next year and kept it that way for many years. So 1975 is an oddball. I can't explain why, but here's a page that shows the variation and another that shows which ones are interchangeable. The link you posted was for an R180. I don't think that you have an R180 in your car. R180's were used for automatic transmission cars. https://www.thezstore.com/page/TZS/PROD/classic22e01/22-1003 https://www.thezstore.com/page/TZS/CTGY/classic22e01