NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

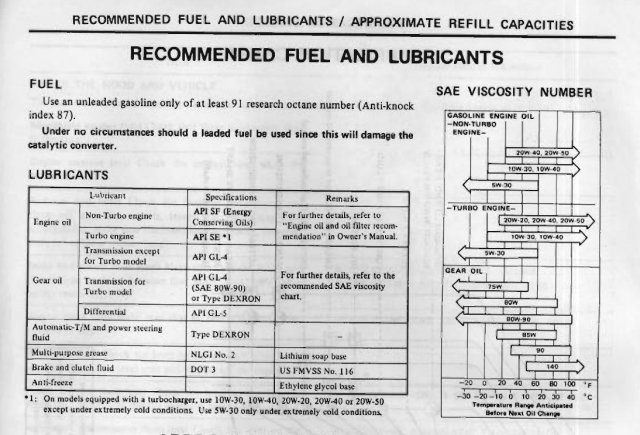

This might explain where the ATF vs gear oil confusion comes from. The FSM implies either. The picture is from the Maintenance section of the 1983 FSM.

-

I have read that a high volume pump can flow more fuel than the return lines on a non-EFI tank and lines can handle giving high pressure no matter what the FPR is set to. You might need to re-plumb your return line to run that high pressure EFI-rated pump.

-

1978 280z poor acceleration and stutters.

NewZed replied to KetchupNinja's topic in Trouble Shooting / General Engine

I think that you lost a lot of people at "MAF" and "blowing tons of money for replacement parts." It's a sad, lonely road that no one wants to travel with you... DCZ is right, if you get the FSM and read the Engine Fuel (EF) section, you'll be able to describe your problem better. http://www.xenons30.com/reference.html It revs really high but barely moves? Automatic transmission? Read the AT section also. Even if you don't get a solution here, you should be able to save a lot of money with your future mechanics. -

Just like the drawing in Post #10. ??? I worry about the world...

-

manual fuel pump compatibility 260z-280?

NewZed replied to the-sleeper-z31's topic in Nissan L6 Forum

From what little I know of the other Z years, the 1974 260s came with both mechanical and electric fuel pumps, in series. Maybe your electric pump is still there. If not, at least the wiring and plumbing should be. Crawl under the car and look around at the front of the gas tank. -

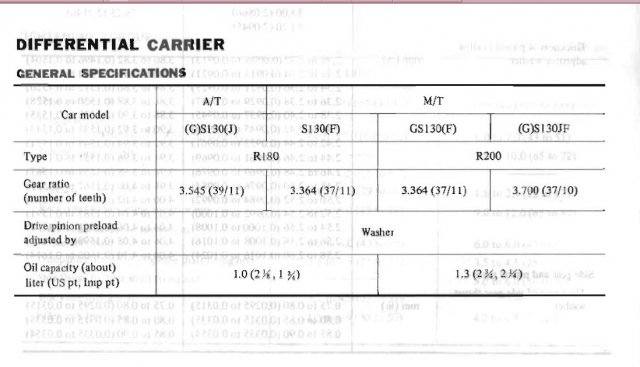

I've been browsing the FSMs lately, planning for a differential swap. The 74 FSM says that 3.364 and 3.545 were available in 1974 but that all diffs were R180s. 1975 shows only R200 3.54 ratios available. But 1979 does show a 3.364 R200. It's odd, but it's there. Haven't seen it anywhere else in an R200. Page PD-21. 1979 also looks like the only year with the 3.7 ratio R200 until 1984. This is just FSM data, maybe there were dealer options that don't show.

-

RT Diff Mount - Necessary to notch lower diff mount?

NewZed replied to The Woj's topic in Drivetrain

Thanks for the info on the car. Looks interesting. I had a faint memory about an old Roostmonkey post so searched and found his Vendor's Forum thread. A lot of what's been discussed here was talked about then. Worth a browse - http://forums.hybridz.org/index.php/topic/85384-rt-mounts-are-ready-for-shipping/ -

RT Diff Mount - Necessary to notch lower diff mount?

NewZed replied to The Woj's topic in Drivetrain

Thoughts and questions - did you make the mount yourself or buy it? And to confirm, you have a 280? And you're running the stock L6 and transmission? Just wondering, I'm not even sure what car you have. Might be some good feedback to the builder, maybe 280s are slightly different. The original RT mount design was for the V8 conversion, I believe, and it was designed to lower the front of the diff to get the pinion shaft on the same plane as the transmission shaft, if I recall correctly. So the comments about getting your angles right are pointed at avoiding vibration when you're done, your shafts won't be on the same plane anymore. What some people have done (quite a few over on Classiczcars.com) is to keep the lower mount,then use a pinion snubber on the RT mount instead of the ES 3-1108. Typically they trim the snubber so that it barely touches or has a slight gap. This avoids tying the diff in too tight and getting vibration. It seems to work for those that have used it, and lets you keep the original pinion shaft angle, but accomplishes the goal of holding the nose of the diff down. Plus you you don't have to worry about grinding your cross member. -

I'm not an expert, but I think that, based on the way the diff works, if you have 30 degrees of rotation on one side, you should have 30 degrees on the other side. So that result is a little bit confusing. Are you sure that some of the play isn't being taken up by the u-joints or axle splines? The vibration problem sounds more like a u-joint issue. You can get quite a bit of movement out a bad u-joint. And from what I've read, the side shafts/flanges on both the 280ZX and 280Z R200 diffs should pop out and you should be able to swap them, if the spline count is the same. I've been looking around at various differential options myself so would be interested in what you have there. From what I've been able to figure out, any R-200 diff up to 1983 should be usable with just a side shaft swap, except for 1975 when they used the weird pinion shaft flange bolt arrangement. After 1983 they changed the pinion shaft flange also. I'm interested. My diff is whining and clunky so I'm planning ahead.

-

1977 280z fuel injection problem

NewZed replied to zsteelman's topic in Trouble Shooting / General Engine

s30red240z has a good point. Maybe you are not getting enough current through the injectors to open them. Or you might not be getting a proper ground through the ECU (same result). Then injectors are powered all the time when the key is On and open when the ECU grounds the circuit. If you have a spare injector, you could plug it in, in place of one on your engine to see if it is opening. s30red240z suggests holding it in your hand because then you'll feel the click as it opens. I recently cleaned my injection harness connections and put newer injector connectors on and now can actually hear the injectors clicking open when the engine is running. Before then, they were barely audible. Your FPR is designed to flow fuel through the rail all of the time. The orifice to the return line gets bigger or smaller to maintain a 36 psi difference between the inside of the manifold and the fuel, but it is always open when there is enoguh pressure from the pump. So if you don't have fuel in the return line, something is wrong. You could pop your CSV out and hit the starter to see if fuel is actually getting in to the fuel rail. Follow your fuel line from the fuel filter outlet through the rail, to the FPR and out to the return line and you'll see how it works. By the way, sucking gas fumes through a shopvac doesn't seem like a good idea. -

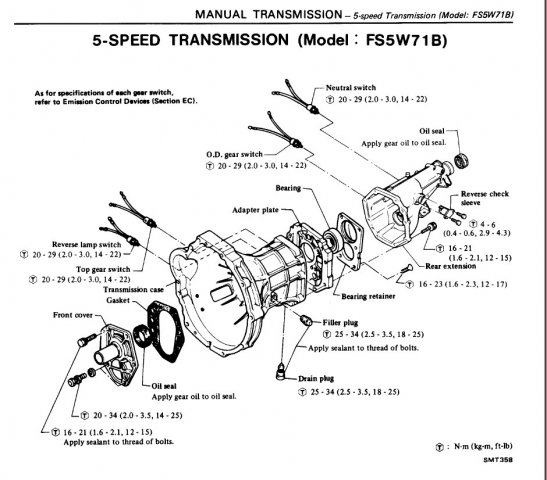

Does it look like the attached picture? That transmission uses 80 to 90 weight gear oil. It's the common Datsun 5 speed. The drawing is from the 1982 FSM. The shifter mounts in the cylindrical piece on the top of the tail shaft.

-

RT Diff Mount - Necessary to notch lower diff mount?

NewZed replied to The Woj's topic in Drivetrain

Most people run the Energy Suspension 3-1108 - http://www.jegs.com/i/Energy+Suspension/355/3-1108G/10002/-1 Maybe it's not as tall as the GM 3201 that you say you're using. That would lift the nose of the diff up. I did a quick browse but can't find a 3201 on the internet to compare to the 3-1108. -

Waiting for the fog to burn off (Oregon)... Do you mean that you bypassed the fuel pump relay (you said fuel pump)? Connected proper terminals, + and -, right at the pump and nothing happened? It's possible to hook them up backwards. You might have a burned relay and not a burned pump. I have read on this forum of people using a high pressure pump with a regulator so your regulator might be okay with a ZX pump. Not sure. But you don't need the high pressure capability. Sounds like you were looking at a fuel pressure gauge. Did it show 3.5 when the engine was running, now it shows zero? Some low pressure pumps are set at a constant low pressure. Unless you've actually seen the FPR and know you have one, you might end up putting 60 psi through your carbs. Sounds like you have an interesting, modified old 240Z. I would spend some time figuring out what you actually have before swapping parts. If you put a 73 alternator on and the car has been modified for a new alt, you'll have problems. Same with putting a ZX pump on a carbed car. Your car is no longer a 1973 240Z.

-

If you're running carbs the ZX fuel pump will be overkill and might cause problems, unless you a have the right fuel pressure regulator. ZX's have fuel injection,using a high pressure pump. You need a low pressure pump or high pressure with a regulator, for carbs. It might be hard to find something suitable in the junkyard since most carbed engines use mechanical pumps. To BRAAP's point - When you had your alternator tested, did they tell you if it was internally regulated or not, or mention if it was a stock 1973 alternator? Converting to internally regulated modern alternators is pretty common. 6K on an L28 is very spirited driving! Mine runs out of steam at about 4800. I wonder if yours has some performance mods.

-

The info on the P99 is probably in the same place as the info on the P81.

-

Looking for info on heads just now and came across the tables on this web page - http://www.zcarz.us/TechnicalInformationPage.htm One shows a P99 for "8/82-Turbo Hyd" but does not talk about it in the text. Just adding to the mystery...

-

Gas tank leaking on 1975. What are my options?

NewZed replied to dpuma8's topic in S30 Series - 240z, 260z, 280z

I have read that the rubber hoses (filler, vent, return, outlet) tend to crack and leak due to age. Worth checking. I plugged a pinhole leak on the bottom of a Pathfinder tank with that two-part epoxy gas tank sealer you can buy in the auto parts stores. It's worked for about 1 1/2 years so far. They changed the shape of the tank in 1978 and went to the mini-spare tire. I think you'll need a 1975 to 1977 tank, for the EFI lines, if you decide to replace it. -

You might have seen this already - http://forums.hybridz.org/index.php/topic/62367-anyone-heard-from-ross-lately/page__pid__917516__st__100#entry917516 I think that there is an alternative, using the earlier half-shafts with u-joints. Maybe while you're waiting...

-

The web page does look like it's for ring and pinion gear sets, apparently, not LSDs - http://www.precisiongear.com/pgtechbreak.htm Can't you just call Precision Gear and see what they recommend? I assume that whatever materials they used, and treatments before during and after building the LSD would matter. Seems like they would know their product best.

-

Can't pull engine because tranny won't come off

NewZed replied to dpuma8's topic in Trouble Shooting / General Engine

-

On this forum - http://forums.hybridz.org/index.php/topic/96164-fs-misc-z-car-eng-parts-prtr-fld-pads-diff-mounts-240-dash-harness-custom-locks-510-hubcaps-etc/

-

This thread is informative - http://forums.hybridz.org/index.php/topic/56329-megasquirt-overview-for-newbies/

-

A three tooth wheel would not work. I just figured out that I don't know what I'm talking about. Just correcting an error...

-

I was just trying to help kce out a little bit (and make a little joke), re the original P90 v P79 topic, plus I'm still interested in the "causes of detonation" discussion that was going on. Yours is an interesting discussion and might be worth extracting as its own thread, as you suggest.