NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Need tuning help/diagnosis '78 280Z Factory EFI

NewZed replied to TheWeekendWagon's topic in S30 Series - 240z, 260z, 280z

Adjusting the spring tensions won't help with idle gases problems. More AFM's get screwed up by fiddling with the spring tension. The atlanticz page is meant for fixing those problems, fixing screwed up AFM's, not "tuning". -

Need tuning help/diagnosis '78 280Z Factory EFI

NewZed replied to TheWeekendWagon's topic in S30 Series - 240z, 260z, 280z

Most AFM's are rebuilt by FuelInjectionCorp. I could run the idle air screw all the way out and it would still run rich. Other people have reported the same problem. I had to install an adjustable FPR to lower the fuel pressure to get it to pass if I did not swap an old Nissan AFM in. I think that FuelInjectionCorp just didn't do a good job of matching specs. to Nissan's AFM. https://fuelinjectioncorp.com/ -

Need tuning help/diagnosis '78 280Z Factory EFI

NewZed replied to TheWeekendWagon's topic in S30 Series - 240z, 260z, 280z

Where did you buy the AFM? I bought a new one and it was rich. I had to go back to an old factory unit to pass emissions. -

240Z Trouble bleeding rear brakes

NewZed replied to rand's topic in Brakes, Wheels, Suspension and Chassis

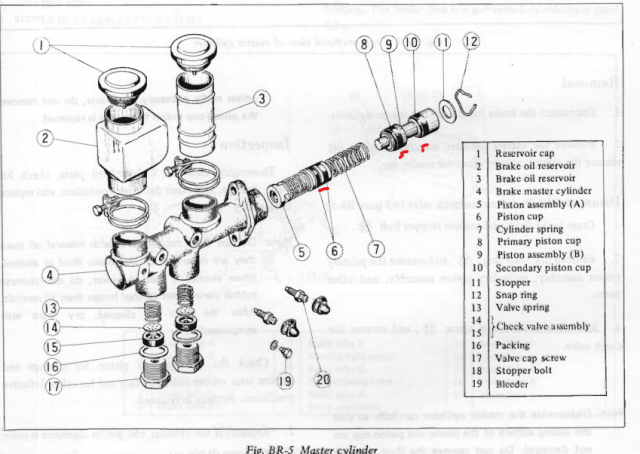

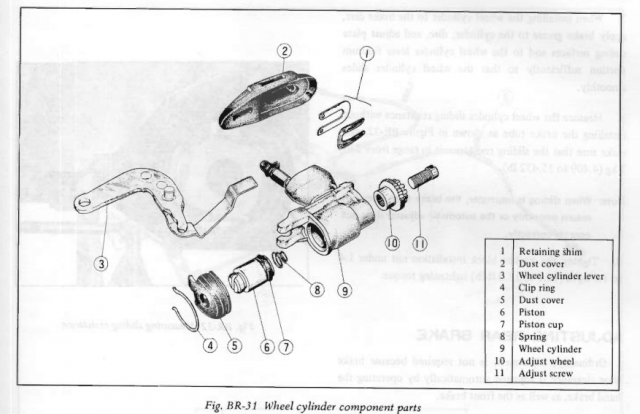

Bleed the front brakes. They can have a big bubble that will take up most of the MC movement. Have you tried pumping the brake pedal? That will compress any air bubbles and create more pressure. If you can get the wheel cylinder to work by pumping that means you have trapped air in the system. And, the MC might have a blown seal. It will push fluid with no back pressure but not when it has to work. There are three seals in the MC, one each to make pressure and another to stop leaks. So, sometimes you can't really tell when the MC is bad. -

You're back! There was a Tony D drive-by about a week ago...

-

240Z Trouble bleeding rear brakes

NewZed replied to rand's topic in Brakes, Wheels, Suspension and Chassis

Does the brake pedal move? Does it drop to the floor or does it stay high and firm? What does "cleaned out" mean? Did you disassemble them? They're easy to take apart. Pull the pistons out, if you can. Odds are that they're rusted in place. -

A set of KYB shocks would be a good inexpensive start on the suspension. If you want to be economical and like the height the car sits at now. Describe what your plans are and you'll get more ideas. There are much more expensive things that you can do to it.

- 2 replies

-

- 1

-

-

- newbie

- suspension

-

(and 2 more)

Tagged with:

-

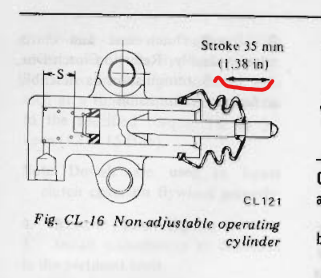

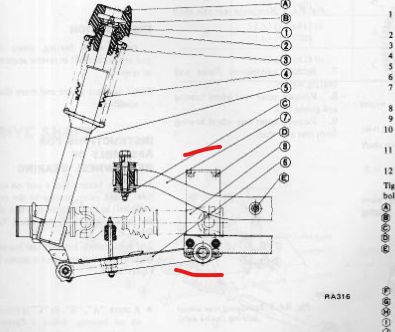

I thought you had the Nissan master working the BMW slave. One way to check for air or leaking seals is to compare the distance the master cylinder rod travels to the distance the slave rod moves. If the cylinders are the same the distance should be the same, of course. Then you can also watch the fork to see if it is getting full movement. If everything is maxed out then maybe the Nissan clutch pedal just doesn't more the master rod as far. So a bigger master would make sense then. Just thinking. I had a slave cylinder that only moved about 1/2 the distance it should. It was leaking in to the boot. If a person just eyeballed it they'd see it move but it wasn't moving far enough. Had to measure.

-

Curious if you know the diameter of the BMW slave cylinder. There have been quite a few questions lately about making the clutch work after an engine swap. Seems like the manufacturers would just match the cylinders and do the geometry at the pedal and fork to get travel, but who knows.

-

Rear caliper pistons won't engage

NewZed replied to YupI'mFrustrated's topic in S30 Series - 240z, 260z, 280z

He said problem solved. He's on to the next one... -

Rear caliper pistons won't engage

NewZed replied to YupI'mFrustrated's topic in S30 Series - 240z, 260z, 280z

It's a well-worn path. Good luck. -

Clutch Master Choice for 280Z with 350Z CD00A

NewZed replied to 280JZFlorida's topic in Toyota L6 Forum

This is the important part. If the pressure plate is the same type as the Z engine, and the fork ratio is the same, there's no good reason to change any of the hydraulics. Slave stroke calculated with fork ratio gives throwout sleeve travel. That's what disengages the clutch. -

Got a tape measure? Take some measurements.

-

Rear caliper pistons won't engage

NewZed replied to YupI'mFrustrated's topic in S30 Series - 240z, 260z, 280z

Try pumping the pedal. If you have air in the lines pumping will push more fluid in and compress it, causing the pistons to move. It will be a clue. And if one side(end) has air it will affect the other side. So you can't just ignore the fronts and expect the backs to be good. You might want to try a power bleeder, to push or pull fluid through. Are the bleed valve passages at the very top of the caliper piston bores? Sometimes they run a diagonal channel from the bleed screw so you have to look at the casting to see where the actual passage is drilled. It needs to be at the top where the air bubble sits. Pretty common for some of the conversion to have bleed valve orientation problems. You might have to pull a bolt and twist the caliper just for bleeding. -

Describe the engine. Post pictures. Start a new thread. This one is very old and looks to be about Chevy's.

-

I said "dog bones" in my post, but I should have said "drop downs" or hangers. The two parts the "dog bone" attaches to to create a square support structure, that the rear of the control arms seat in.. It's not clear from their drawing if they got rid or that or not. The two studs for the mustache bar weren't meant to handle the lateral forces that they would see if those guys are really using them as the attachment points for the cradle. Those two studs just direct the mustache bar forces and have to handle the inertia of the eighty pound diff on corner. Full disclosure, I'm just here for the puzzle. Some pictures of the parts actually in a car would tell a lot. Poor marketing.

-

It looks like they're also using the mustache bar hanger bolts as the mounting points for the back of the control arm hardware. They got rid of the "dog bones". Definitely some odd engineering going on.

-

But, with the picture it is possible to guess at what you meant. There is a solid metal path from the diff's back mount up to the cradle's front mount. The bushings are basically useless, except for allowing for manufacturing error. Loose tolerance. As the diff nose comes up it will lever those back tabs because the diff's front bushings will let the nose move up. That's as the drawing shows. The drawing might be wrong. The factory Z control arm mounts have bushings at the front. Maybe they forgot to put them in the drawing. That would make the cradle fully floating, in rubber bushings. It still leaves the diff housing half solid and half bushed, as you said. It lets the diff apply bending forces to the cradle alone. So, it is kind of a goofy design. Well made though. They need to either make the diff fully bushed or the cradle. The drawing shows that they went halfway on each. Too bad they don't have some pictures of the parts in a car. Weird.

-

You should write better. Not kidding, your post isn't clear. The Ford diff housing is "bushed" around the mounting bolts. You only talked about the front of the diff. Maybe you meant something else. Or maybe you got the wrong bushings with your diff. Unclear - "There is no bushing where the front of the cradle attaches. There is only bushing on the mustache bar. Thus the cradle is half solid mounted half soft mounted. There is the stock bushing on the front of the diff to the cradle, but then there is just a rubber bushing shoved in as a washer between the diff cover bolts to the mounting tab,"

-

It is kind of funny how few pictures they have of a differential housing actually mounted in any of their systems. Hundreds of pictures of fabricated steel but almost none of an installed system. They could use a marketing class or two. Here's one that shows the Ford bushings in place, with the rest of the Z car system. Even this page and photo doesn't even really tell you what it is. Fabrication skills and business skills aren't often found together.

-

Front strut replacement questions

NewZed replied to Tarheelz's topic in Brakes, Wheels, Suspension and Chassis

Stick a piece of all-thread in a drill and use two nuts to attach a piece of abrasive material to the all-thread. It took 30+ years for that rust to build up. Be careful with the POR if you put it on too thick you won't be able to get the shock in the tube. Get it too thick on the bottom and your gland nut won't fit. -

They're out there somewhere... https://www.facebook.com/apexengineered/

-

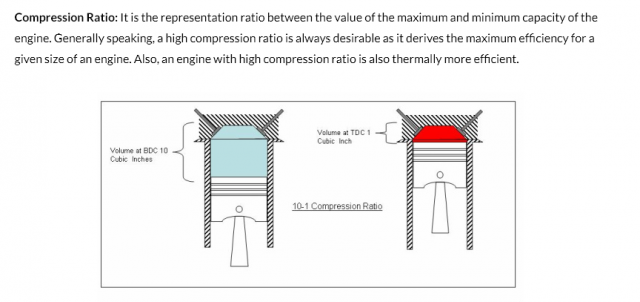

That's a good point. I might be wrong on the second part about CR, haven't had the thought in my mind for quite a while. The displacement part is right though, and that's how engines are described. Size. My mistake. https://engineeringinsider.org/basic-definitions-used-engine-terminology/3/

-

Front strut replacement questions

NewZed replied to Tarheelz's topic in Brakes, Wheels, Suspension and Chassis

-

You must be thinking of total cylinder volume at the bottom of the stroke. The combustion chamber is not included in displacement. Because "displacement" is, literally, the volume that is displaced, or moved, by the piston during its stroke. You could call it "swept volume", for example. Compression ratio is the displacement volume divided by the combustion chamber volume. All of that displaced material is packed in to the tiny combustion chamber.