NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

I referenced duragg because he's a pragmatic guy who was actually running his race car (that he built) to 7500 RPM. One more opinion. I've seen CM's posts since he joined various forums. He used to be just a guy with lots of parts counter experience. Now he writes like Carroll Smith, but driving also. Very much like Carroll Smith, I have two of his books. Smith's, not CM's. The grain of salt is always in play. Take it from someone who actually has spent a lot of time on the internet.

-

It was a good discussion. My preference is to do things to the appropriate level maybe with a little bit of insurance. Duragg spends a lot of time at 7500 RPM, maybe higher. He got deep in to transmission synchro design to get his trans to shift well up there. Maybe he has some real-world L-series knowledge to pass on. He has since switched engines but he used to have an L. I don't know if the at's really work but it's worth a try. Mine's just a test. @duragg @NewZed

-

Might as well go all the way. Don't want the crank nose end busting off and taking out a crowd of people.

-

This thread ended up just like all internet threads.

-

I was just making a point. The internet is full of advice about over-doing things. If you're on a Ford forum they're fanatical about buying only Motorcraft parts, for example. People slather anti-seize over every bolt if they've ever had a single stuck one. People use lock washers and Loctite and over-torque, just to "be sure". The damper is a simple mechanism. Just make sure the bolts fit correctly, the threads are clean, there are no burrs in any critical areas, use some blue Loctite or any other brand of threadlocker, and run with it. Bolts don't just back out. Most of the damper problems you read about are probably from poor fitment of the damper on the crank snout. BHJ has some good stuff on their web site. #5 in the first paper, and general installation instructions. Notice that they don't even talk about the bolt in the installation paper, it's all about getting the damper correctly mounted on the snout of the crankshaft. The bolt is assumed to be the easy part. Just torque the right bolt down on top of the correct washer. If the damper fit isn't right the Loctite won't save you, is the point. I'm overdoing it myself, in this post. Good luck. http://www.bhjdynamics.com/downloads/pdf/tech/BHJDynamics_Damper_Info.pdf http://harmonicdampers.com/downloads/pdf/tech/BHJ_DamperSteelInstallPress.pdf

-

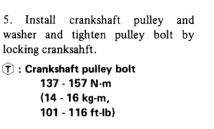

By whom? Thread lockers are neat, and good insurance, but Nissan didn't feel the need for any special instructions at all. The basics of how bolts work is all you really need. They're just clamping devices. Don't make it over-complicated. Much of the red Loctite usage probably comes from people who didn't do things right the first time, had problems, and are overcompensating the second time around. Here is all of the effort that Nissan put in to their instructions.

-

It worked. Yes, the L-series link is hidden. Ron Tyler did that when he reorganized things. Seemed like a good idea, but it's somehow invisible up there. Lots of people miss it. and it's where most of the good stuff is. Since you're here - the vigilink monster is back. Click my links in this thread.

-

This might help. I always have a problem figuring out what is superceding what though. http://www.carpartsmanual.com/datsun/Z-1969-1978/brake/brake-clutch-pedal http://www.carpartsmanual.com/datsun/Z-1969-1978/brake/brake-clutch-pedal/16

-

This one. Displayed as a link so that you can see the address. Might be the junk at the end. Looks like some truncation and mangling has occurred. I tried modifying the end of the address but it keeps adding the junk symbols. Might be a length problem. - http://forums.hybridz.org/topic/46043-using-a-degree-wheel-to-degree-in-your-l-series-cam…/

-

JMortensen has written about how the early 240Z's had incorrectly drilled strut castings. The spindle pins are off the design axis. Here's a start -

-

L28et swap not starting/staying on

NewZed replied to superduner's topic in S30 Series - 240z, 260z, 280z

Even the ECCS system is not too complicated to follow the wiring diagram and figure out how the injectors get opened. I always get in to trouble when I only follow instructions. Are you sure that they're not just stuck open and the noise is the fuel pump, or FPR? The typical failure mode of the 280Z EFI ECU is to flood the engine, due to something in the ECU shorting the injector power to ground. You might unplug your ECU and see if the injectors still spray. If they don't the problem might be in the ECU. If they do, you have a short to ground somewhere else. That's the key to understanding injectors. They open when the power is grounded. You could also unplug all of the injectors, electrically, and see if the buzzing noise is still there. If it is, it's not the injectors. You could disconnect the dropping resistors to remove power and do the same. Lots of ways to troubleshoot. And your description of what's happening isn't super clear. Were you holding the key to Start while the injectors were spraying, or did you let go and it was at On, or was it off? Lots of "after cranking" possibilities. -

Assistance needed with 240Z seat ID

NewZed replied to ///Mink's topic in S30 Series - 240z, 260z, 280z

A ton of good pictures and stuff in the FSM. -

My 350 (probably) powered 260z!

NewZed replied to nolant178's topic in S30 Series - 240z, 260z, 280z

Looks like your pinion haft was about to blow a hole in something. It's trying to get out. It happened to me long ago, on a GM diff. Blew a hole in the diff cover. Look at how the propeller shaft turns those gears and how they work. Ponder how the gears could turn and slip on the broken teeth when the car is not moving. -

My 350 (probably) powered 260z!

NewZed replied to nolant178's topic in S30 Series - 240z, 260z, 280z

Yes. The R180's and R200's are notoriously loose and clunky diffs. Lots of slop in the gears, and splines. In neutral there's no load. Good luck. You'll find it. -

My 350 (probably) powered 260z!

NewZed replied to nolant178's topic in S30 Series - 240z, 260z, 280z

The driveshaft could easily transmit motion to the diff, making the pinion gear bounce off of the ring gear. The noise might be from the diff but the problem is probably in the trans or converter. There's no way the car would move like it does if you had a tooth missing. And at zero MPH the pinion gear would have to be slipping over the ring gear. That would make a terrible grinding noise. Put your camera under the car while you do the zero speed load test. You'll probably see the propeller shaft bouncing back and forth a degree or two. On the other hand, taking things apart is always a good learning experience. You'll want to know your diff condition anyway. The R180 really is small for a 350. -

Lowering with Strut Insulators

NewZed replied to Whitley_280z_2+2's topic in S30 Series - 240z, 260z, 280z

The swap from front to back sounds like a good idea. Is the height difference what you want? If the three holes are the same dimensions, it should work. You'll just have an extra, useless, bearing in the insulator. As far as handling, you're not changing any geometry just the starting point of the struts. I found that lowering, in general, improves handling, by lowering the center of gravity. -

My 350 (probably) powered 260z!

NewZed replied to nolant178's topic in S30 Series - 240z, 260z, 280z

I looked through the thread and can't tell exactly, if the car has an automatic transmission. But, if by "not moving" you mean zero MPH, then the problem is probably in your torque converter or transmission. The wheels, differential and various drive and propeller shafts are all solidly locked together. The only part that can move with the engine crankshaft is the torque converter and transmission input shaft, if the car is not moving. When I watched your video "torque converter" popped in to my head as a cause. It might be as simple as loose torque converter flex plate bolts. I would check them soon, the beating will be damaging. -

Quite a few people on classiczcars.com are using it. Not to send a Hybridz member away but that's where the 123 action is.

-

That makes sense. MS is developed enough to have an output for that function, the same signal that they use for their data logging and visual software. Good luck.

-

You're on the right path, taking the time to understand the details of how your tach works. But, there are still coils involved with your MS setup. I don't know how many, but if it's not one supplying six spark plugs, then it's probably three (wasted spark) or six (COP). So, the Technoversions unit has the most promise, because if you can set it to a multiple of six, and use it on one of the single coils, then you can get the tach to read right. The MSD adapter just conditions the signal for a single coil. You can't change the multiple it sends to the tach. It won't work unless you do some trickery. And it often does not work for people, even on applications it's designed for. I think that it should be possible to gang the triggers from all of the coils in to one trigger wire and use that for a single coil type adapter. You'd probably need some resistors and diodes to avoid cross-talk and noise but it should be possible. I'm kind of surprised that nobody has rigged one up, the concept is pretty simple, the tach needs are well known. If I had MS I'd send that guy at Technoversions and email and see if he'd be interested in expanding his product line to handle wasted spark and COP. He'd have a pretty big market, I think.

-

-

Does anyone have experience with these filters?

NewZed replied to dpascual1986's topic in Nissan L6 Forum

K&N are not "regular" oiled filters. They're worse oiled filters. Really, all you're doing here is comparing two turds. Which is the better piece of junk. -

My 350 (probably) powered 260z!

NewZed replied to nolant178's topic in S30 Series - 240z, 260z, 280z

.....no..... 280ZX's don't use a mustache bar. You need a 280Z bar. But you can use a 280ZX dif. You need the piece that connects the two drop down supports, that the back ends of the control arms, with bushings, are attached to. It is s curved for the R200, your R180 piece is straight. People call it the dogbone. And a 280Z R200 front differential mount. Or an RTz design mount, which he designed for V8 applications. People have finagled the R180 parts to make them work but getting 280Z parts is easier. Here is a link to a guy who sells the RTz style front diff mount. https://www.technoversions.com/ Since you're under there you should really just check all of the rubber bushings in the area. There is a lot of rubber that is now dried out and aged. Post up some good well-lit shots of the the rear suspension mounting points and the diff and we'll pick it apart. -

My 350 (probably) powered 260z!

NewZed replied to nolant178's topic in S30 Series - 240z, 260z, 280z

I didn't read the whole thread. I just saw the "probably" and assumed it meant future 350, not 350 vs 327. I watched your video. One way to differentiate between the two halfshafts and a wheel or bearing problem, and the propeller shaft and diff, might be to find a big parking lot and do tight circles, both left and right, at the same speed. If it's a half shaft or wheel bearing or wheel the noise will be faster when that shaft is outside, because it's spinning faster. If it's the propeller shaft and/or diff it won't change as long as speed is the same. So, basically, if the speed of the noise changes depending on which way you're turning then it's somewhere after the output of the diff. If it doesn't it's inside the diff or before it. The basis of why they call it a "differential". A diff swap is all big bolts and heavy objects. Nothing to be nervous about. -

My 350 (probably) powered 260z!

NewZed replied to nolant178's topic in S30 Series - 240z, 260z, 280z

I've seen your other posts about the broken side plate and just realized that you're planning to install a V8. Might be more cost effective to swap to an R200 instead of fixing the R180. The way to evaluate a u-joint is to stick a long screwdriver or other thin metal bar into the yoke and reef it around while shining a bright light on the cap seal area. If it's worn you'll see it move. If it's worn and dry, red powder will be apparent at the seal edge. The seal might even be cracked and broken. Heat on the yoke helps a lot for changing u-joints. A lot. You can evaluate the diff by removing the cover and examining the pinion shaft hole for slop and wear. The R180 is not a good choice for a V8 though. Too much torque. You'll either stress the diff itself or do lots of one wheel burnouts, which are bad for it too.