NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

In the Nissan Factory Service Manual. It's from the days when people could read a page or more in one sitting. I'm a dinosaur.

-

-

Hasn't? Did you mean "has"? Is there a real problem, is the question. The system is designed to move and flex and dance around a bit. Is something breaking? Many people have found that the solid front diff mount is a mistake. You might be over-solidifying. Maybe go back to a more flexible front mount, like the RTZ style mount. In an endurance racer, driver comfort is a factor and having the diff solidly tied to the body could be am auditory torture device. Isolate the diff noise, let it move, let the u-joints get a little work-out (makes them last longer). Even the AZC billet mount uses PU bushing ends. If you fasten the the mustache bar to the dog bones you'll be at full metal jacket level.

-

Somebody on this forum has a pretty nice 2+2. Maybe Careless? Can't tell. The new site software seems to have destroyed all information about members. http://forums.hybridz.org/profile/1767-careless/?tab=activity @Careless

-

Odd that a person would install a short-nose diff but with different internals. Why not put better guts in the long-nose R200 it came with? And I thought that AZC had pulled their short-nose diff setup for reworking, because it's hard to get the short-nose mounted firmly. Looks like a nice collection of parts though. "From the output shaft, the driveshaft spins up a Q45 R200 differential with a Tomei 1.5-way limited slip differential. " Here's a link to the info part - http://www.speedhunters.com/2017/11/gas-monkey-garage-goes-jdm/

-

Acquiring a 76 280z, now I need to put a V8 in it

NewZed replied to Fat Dahry's topic in Gen I & II Chevy V8 Tech Board

Here's the manual that I was thinking of. I get Jags That Run and John's mixed up. I think that somehow they are connected but not sure of the details. http://www.jagsthatrun.com/Pages/Datsun_Z_V-8.html Here also is another kit from a pretty reliable Z parts supplier. http://www.thezstore.com/page/TZS/CTGY/classic13 They probably jumped in to to fill the void when Broken Kitty dropped out. Most people are in love with the LSX swaps these days, even though the old small block swap has the bugs worked out and is pretty much a paint-by-numbers swap. Good luck. -

Acquiring a 76 280z, now I need to put a V8 in it

NewZed replied to Fat Dahry's topic in Gen I & II Chevy V8 Tech Board

Sorry, I always miss the title information and focus on the post. Missed the 1976 in the title. There are a ton of options for you. Carbs and a distributor and a motor mount kit are pretty simple. Choice of transmission is a fairly big deal, any manual transmission can add a lot of cost. Choice of how to build the engine is not really related to the car. It's just an SBC thing. There's a book on this web site that most people recommend. Looks like the web site is pretty messed up though. Might be better to call. http://www.brokenkitty.com/zcar.htm -

Acquiring a 76 280z, now I need to put a V8 in it

NewZed replied to Fat Dahry's topic in Gen I & II Chevy V8 Tech Board

You didn't say what year Z you're getting. That will be a factor. And things have changed a lot since installing an MSD ignition system was significant. No offense. That's small potatoes though compared to the other work you'll need to do. -

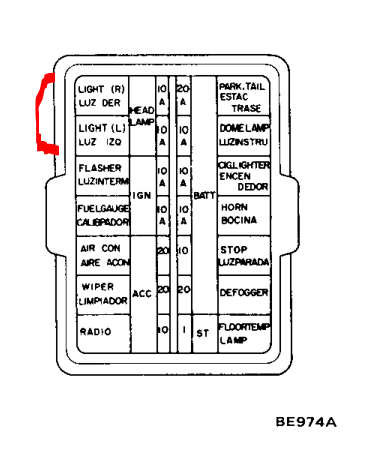

The dimmer switch is the most common problem. Then a broken solder joint at the HL switch itself, on top of the steering column. There's also fuses.

-

If you're using an extender to make it easier to reach the plugs, or a long hose, that will lower the pressure reading. The extender tube and/or the long hose effectively become part of the compression chamber, lowering the testing compression ratio. Nissan's 170 psi number is only valid if you're using their pressure measuring tool. They kind of screwed up by not mentioning that. If you look at their picture though, they're using the smallest connection volume between cylinder and gauge. so they get a high number.

- 31 replies

-

- fml

- more z car torture

-

(and 1 more)

Tagged with:

-

This seems to explain the inherently never-quite-smooth idle of the factory EFI system. Different cylinders see different injection timing. It's always bugged me. Maybe you could fabricate a small venturi in the ports and inject in to it so that the ITBs act more like a carburetor. JK.

-

Did you fix the Hybridz image links? They work now, but they haven't for a while. Either way, they work. The Photobucket thing is a different problem. I meant that I could not type any text in to the message box when I was trying to send you a message. I had to fake it out and "choose file" of a picture of a message. Notice that there are no words in my message, just a picture of some words. Thanks for fixing the images, if you did.

-

That's pretty cool, thanks for the info. It didn't fix the Hybridz owned images but it did fix the Photobucket image. Maybe Google is paying the third party fee and sharing. Peanuts for them. I used the first, top extension. BUT. It does not work in Incognito mode. Just have to open another Chrome window. And I thnik you left a step out - click "Add accessibility features", under "Accessibility", then the search box will be there.

-

I'm kind of surprised that SuperDan didn't respond. It's in Site Support. I just sent him a message about it. Had to send him a picture of a message though because the message function now has problems. Hope he gets it.

-

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

NewZed replied to RefreshRate's topic in Nissan L6 Forum

That would be just the propeller shaft, aka driveshaft. Nissan called the "half-shafts" driveshafts, and the driveshaft a propeller shaft. You'll need a new fuel pressure regulator also. If you're making a list. Might be best to do a lot of reading before spending. There are are many combinations of parts you can put together. Some sort of performance goal is a good thing to define, and put the parts together to hit it. Your list of parts probably won't feel much different than what you have now. For the money spent. -

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

NewZed replied to RefreshRate's topic in Nissan L6 Forum

Does 240Z driveline mean engine to diff? Or just transmission to diff? Or just transmission and driveshaft? The 280Z came with an electric fuel pump already for the stock EFI system. Nice looking car. Is this the "Stage 3" camshaft? http://www.thezstore.com/page/TZS/PROD/classic12e03/10-2003 There are many options out there. Some people say that you can go a lot "bigger" on the camshaft than you'd think. Search jmortensen's past threads. Here's an example - -

Edited. Sorry folks. I guess I've been spoiled because of the general high level of the site when I joined. It's not the same now. If you did figure it out, why didn't you share the solution? You've already discovered that it's a problem. That's really what the forums are for.

-

It was the LOL's... Why didn't you respond, if you understood?

-

I think that nobody offered advice...LOL... because nobody does what you're doing. Plus it doesn't make sense. You're not "building" a viscous LSD, you're using a housing that held a viscous LSD. You could have used an open diff housing and installed an OS Giken LSD in to it. Just saying...LOL... that you didn't get advice because you didn't really describe well what you were trying to do.

-

The problem is general. Some of the answers, and the overkill application of the pump. It's just bad system design. Here's a nice collection of data in one spot. https://www.highflowfuel.com/i-13775895-genuine-bosch-044-320lph-inline-fuel-pump-includes-an-fittings-of-choice-0580254044.html

-

People are making general comments that just aren't specific and not quite right. It's just confusing an already confused situation. The check valve is installed in the fitting at the outlet end of the pump. You'd have to disassemble the pump and intentionally remove the valve, for no apparent reason (just checked the internet and I see that people actually do that - for no apparent reason, apparently, except that they think it's "not needed". Maybe weight savings?...see last comment below...). The leak-down problem with aftermarket regulators is just the result of cheap engineering and low-cost manufacturing. The guys that make them will tell you it's a design function, to allow high-flow, but that's BS. When people get in to the putting these systems together they almost always go overboard on the simple irrelevant stuff and miss the basics. As you pointed out, his pump is way overkill for the rest of the system, and for the engine he's running. One of the basics of DC pumps is that they pull more amps as they work harder. So, with a flow restriction he's going to pull more amps and get low fuel pressure. The signs are there that his fuel system is out of balance, and over-spec'ed . He'd probably do well to get a lower flow pump, and fix his flow restrictions. Wouldn't be surprised if he has one of those tiny anodized fuel filters in-line, probably choking flow. No offense dpuma. But avoid the hype and the bling, and do the proper math is the way to get things working right. https://www.rceng.com/technical.aspx K&N filters. Cold air intake. Bosch 044. Turbo injectors. Electric fans............

-

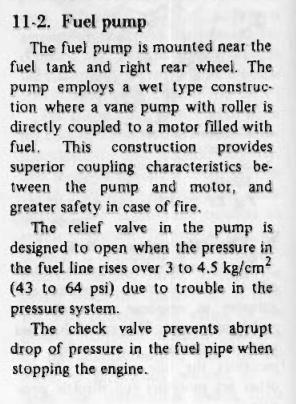

All kinds of different things are getting mixed up and blended here. Retaining pressure when the pump's not running, maintaining pressure while driving, fuses to protect the wires (the device, the pump, is actually a current limiter and protects itself), low battery causing driving problems (what's the alternator doing while the engine is running?). You need to separate out and work on single problems. And get the cause and effect right. Here's a few things - the fuel system is designed to hold pressure for quite while (weeks or months have been seen in wrecking yard cars) after the pump shuts off. There's a back-flow valve in the pump, and the regulator is a pressure relief valve. Aftermarket regulators are almost all poor at holding pressure. If you have low pressure while driving it's probably an obstruction in the lines or a bad regulator. When the engine's running the alternator will supply enough voltage to run everything properly. It might overwork itself if the battery is dead but it will still put out current as long as RPM are up. The voltmeter reading will be a clue. Are you running two pumps on one circuit? The low pressure Carter pump counts too. There's a lot of backyard advice in the thread. Be careful and check multiple information sources.

-

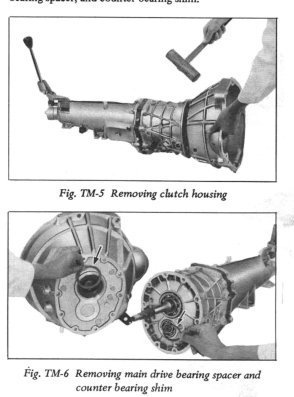

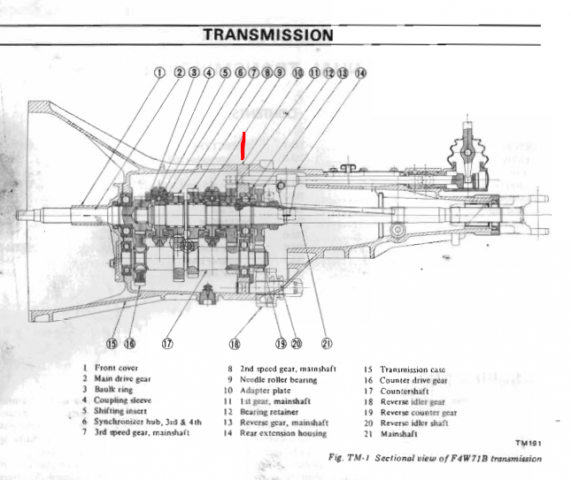

The FS5W71B does not really use a "bell housing'. It's a combined bell housing and front gear case. If your FS5C71B uses a separate bell housing like the FS5C71A then it won't work. I could only find a picture of the A model, not the B model, in the 1972 FSM. The W and the C designate the type of synchro system I believe, so if the B designates the case style you might be able to use it. But. That FS5C71B might be worth more to a restorer. You could probably trade it for a worn out transmission that will work better. There are small issues with the early cases, like the reverse switch location (mentioned in that ZHome writeup, I think), that can be avoided with a later model case. The A transmissions are three piece, and the B's are two piece. Steel plates separate the aluminum pieces.

-

Did the links get broken during the move to the new software? They're jot Photobucket, they should be on the Hybridz server, I think.