NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Tension Rod T/C Kit gauge measurement

NewZed replied to ironhelix's topic in Brakes, Wheels, Suspension and Chassis

You could scale it from the picture. Measure what you have and scale it up. -

Tension Rod T/C Kit gauge measurement

NewZed replied to ironhelix's topic in Brakes, Wheels, Suspension and Chassis

Might help to add some detail to what "it" is. What needs to be measured. -

cg, I think that you're mixing the throttle blade bypass (the AAR) with the AFM vane bypass (the screw in the AFM). The first just raises the idle speed, the second doesn't change idle speed directly but it does change the air'fuel ratio, by letting air past the AFM vane. I didn't answer the last question because it's kind of like asking if you should part your hair on the right or on the left. Doesn't matter where, you still have to get through the test.

-

There are two of them.

-

If I don't pass I adjust it outward until I hear the engine stumble a bit then run it back in a turn. You're supposed to use a gas analyzer. In Oregon we get unlimited tries, so, one or two passes and you're done.

-

There should be a big silver sticker on the driver's side door jamb that says either Catalyst or No Catalyst. Sometimes the guys get confused when they see the spot for it underneath or they just assume that all cars have converters. The sticker is what matters though, make sure to point out that it says NO catalyst. Unless the car started in CA then you need to put it back on. Federal law, no tampering. If I recall correctly, high CO is due to incomplete combustion. Your hydrocarbon levels are under though so you're not far off. You can probably get there by opening up the idle air bypass screw on the side of the AFM, under the rubber plug. Turning it outward lets more air past the AFM vane, leaning out the idle mixture. Also, set your timing to spec. If it's too far advanced you can get misses, that will cause problems.

-

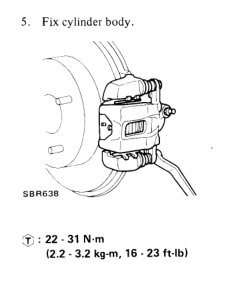

MSA rear disc conversion brackets problems?

NewZed replied to 383 260z's topic in Brakes, Wheels, Suspension and Chassis

Rockauto says the rear 280ZX rotors are 258 mm. Shows the 300ZX as 290. That would be a (32/2 = 16) mm pad contact area difference, not 9 mm. But, like Miles says, you need to confirm the diameter of what you got. Looks like you got everything that MSA said to get though. Who knows. http://www.thezstore.com/page/TZS/PROD/24-5581 -

MSA rear disc conversion brackets problems?

NewZed replied to 383 260z's topic in Brakes, Wheels, Suspension and Chassis

Yes, that's not going to work. MSA should know that. They must be depending on their kit supplier to know what they're doing. They gave you bad advice. You can do the math on the 300ZX rotors. They are 18 mm bigger in diameter, so 9 in radius. You'll gain 9 mm of pad coverage. -

MSA rear disc conversion brackets problems?

NewZed replied to 383 260z's topic in Brakes, Wheels, Suspension and Chassis

How much of the pad area is contacting the rotor? That's what matters. If the pads are only partially in contact, that will put uneven pressure on the pistons. Focus on the pads. -

Stiffer drop mounts and moustache bar

NewZed replied to EF Ian's topic in Brakes, Wheels, Suspension and Chassis

Big picture, engineering-wise, if you do find that you lose traction because you've stiffened the chassis, you could just change your shock damping to get it back. What you're suggesting seems more like urban voodoo racer magic though. Besides that, you're really only stiffening for side to side loads. Cornering loads. So, if you're not talking about launching out of a corner it wouldn't seem to matter much. Straight line launching is more through the struts. Burleigh used to make a new solid "dog bone" for the finned covers. Looks like he hasn't been on the site for about a year though - -

MSA rear disc brackets conversion problems?

NewZed replied to NewZed's topic in Brakes, Wheels, Suspension and Chassis

That's goofy. Couldn't tell if full pad contact is being made, or if half the pad is only making contact. If all of the pad is making contact then the outer portion of the disc gives max leverage. but the discs I've worked on always have about 1/8" of uncontacted edge on the perimeter. Who knows. Here is Nissan's 1982 ZX picture. Seems to show what Big Phil is saying. Maybe Nissan just decided to use a smaller pad instead of a smaller disc, to balance back to front. Not very weight effective though. -

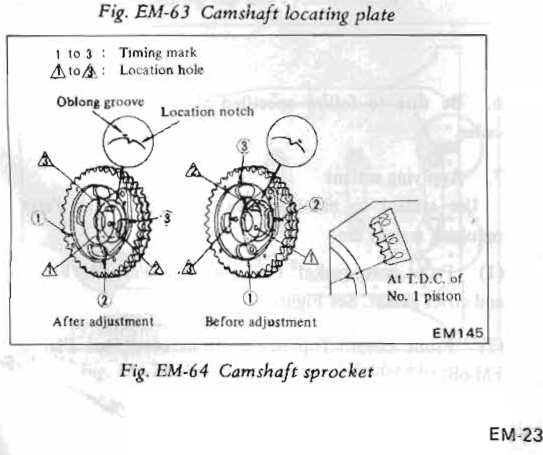

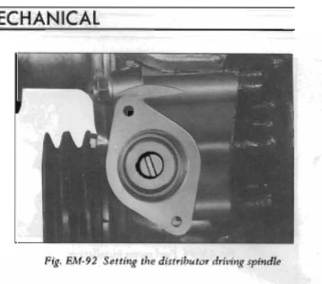

After alot of work car not starting

NewZed replied to M_Motorsports's topic in Trouble Shooting / General Engine

-

After alot of work car not starting

NewZed replied to M_Motorsports's topic in Trouble Shooting / General Engine

The chain almost never skips a tooth. I think that that idea is from the days of the Model T or somewhere back there, used to explain things not understood. The Haynes manuals are known to be poor for the L series engines. Use the Nissan FSM, which is free almost anywhere you look on the internet. Seems like you didn't get the gear aligned right. Posted a picture, note that one half moon is smaller than the other. The small one goes forward. Also, I have found that if you put the wires on in reverse rotation order the engine will still start but run very poorly. Odd but true. -

MSA rear disc brackets conversion problems?

NewZed replied to NewZed's topic in Brakes, Wheels, Suspension and Chassis

Just tried to send the guy a message but the text box would not open, so I couldn't write anything. I had to create a junk file to insert before I could send the message. I put the actual message in the title. Didn't we just have a big fund-raising drive so that new better software could be purchased and installed? The site seems to be going the way of zcar.com. Lots of things aren't working. -

Need help diagnosing noise.

NewZed replied to Stephen_ha's topic in Trouble Shooting / General Engine

Did you do both at once or did you just throw in the part about the SR20? In other words, did it work well with the SR20 and transmission before you installed the 300ZX diff? You might try rolling backwards down in a hill in neutral to see if it's a load thing or a direction thing, or both. If it makes the noise in neutral, no load, it might tell you something. -

-

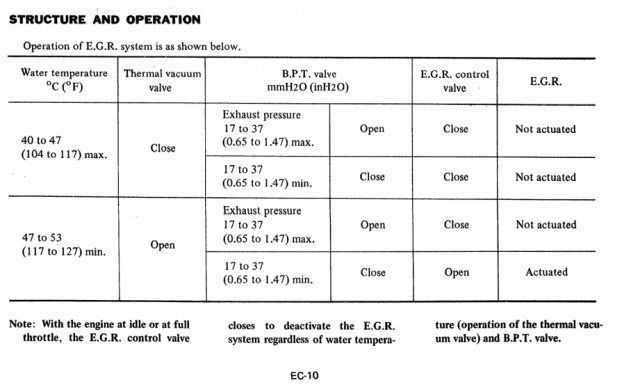

What type of test are you trying to pass? Just idle, or idle and 2500 RPM? Or some sort of visual? The hoses and devices are shown and described in the Emissions chapter of the FSM.

-

What have you read? No use repeating it if it's been read already. There's at least one pretty long and somewhat informative thread on Hybridz, and two web sites with lots of swap details, part numbers, pictures, and measurements.

-

I would give a better description of what problem you're trying to solve. You said it wouldn't start after a radiator replacement. Your title says "won't start". But now you say it won't rev. And, apparently, it ran fine, you drove it for two hours to get it home. But them it wouldn't rev past 3500 RPM. So, which of the many problems are you asking about?

-

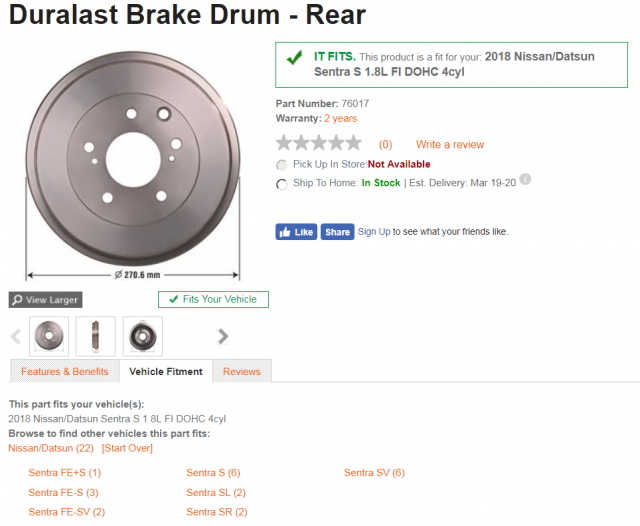

Yes - another Brake Thread. S12W and drums?

NewZed replied to PrincePaul's topic in Brakes, Wheels, Suspension and Chassis

That's not a counterpoint to my point. Which was to your point about wheel cylinder "blow-outs" as a reason to switch to discs and calipers. Your statement implied that drum brakes are inherently unsafe. I was showing that they are not. You're digressing. Back to the original point about performance - I'm pretty sure that some of the guys that race their cars, or have, have pointed out that the typical front brake "upgrade" to bigger calipers and discs adds unsprung weight. Which is a suspension performance downgrade. My main point is to define clearly what you're trying to accomplish. Don't just bolt on parts that somebody on the internet said were an upgrade or that one of the aftermarket suppliers is selling as an upgrade. The advancements come from the people that think out their projects and choose the parts that do the job. The thread seems to be trending that way, so carry on. -

Yes - another Brake Thread. S12W and drums?

NewZed replied to PrincePaul's topic in Brakes, Wheels, Suspension and Chassis

Drum brakes have been around and dependable for many years and are still in use on brand new cars from reputable manufacturers. Worrying about a cylinder blow-out, or a spin-out just doesn't seem to have much weight. Just trying to stay on the path of solid reason. -

Yes - another Brake Thread. S12W and drums?

NewZed replied to PrincePaul's topic in Brakes, Wheels, Suspension and Chassis

That's what the brake pressure differential switch is for. To light up the Brake light. Caliper seals can blow out too. You're kind of giving the irrational "reason" to upgrade. Better to just admit that you want shiny brake parts. One rational reason, to me anyway, to convert the backs to disc is that they stay in fine adjustment. The drum brakes will feel different before and after a click on the adjusting wheel. The pedal will be higher after a click. -

280z still not starting!!!!

NewZed replied to HOLLAATYABOYY1's topic in Trouble Shooting / General Engine

Here's a simple test that you can do to test the injector opening circuitry of the ECU, and the wring harness. It's been described by a few people over the years and you can figure it out from the first few pages of the Engine Fuel chapter. Take a jumper wire and attach one end to the negative terminal of the coil. Let the other end hang free. Turn the key on, so that the coil has power and the EFI relay is energized, and tap the loose end of the jumper wire to a good ground. This will cause the coil to spark. Every third tap should cause all six injectors to open. If you get the injectors opening then you'll know that, at least, the required circuit is intact. It won't tell you how long the injectors stay open but it's a simple confirmation. If you get coil spark but no injectors opening then you have a problem, that you can focus on. You still seem to be looking at things that are easy to reach instead of the things that might matter. But, you'll know a lot more when you're done, either way. Good luck, have fun. -

280z still not starting!!!!

NewZed replied to HOLLAATYABOYY1's topic in Trouble Shooting / General Engine

This might get you close.