NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Must have been imported from Canada. Edit - more info. Could be Germany, France or Holland. http://zhome.com/History/240ZProduction/240ZProduction.htm http://xenonzcar.com/s30/VIN.html FSM page GI-2...

-

That's not really how pressure works. Apparently, Nissan got rid of the liners for the turbo engines because they tend to break free and destroy the turbo. People do use the N47 head with turbos though. It's just a risk. As I understand things the flow obstructions are mostly on the intake side.

-

Just curious. How'd you break it?

-

Pretty sure I've read comments from guys that know suggesting that you mark the position of the nut before removing it then slowly work the nut back to that position when reassembling. Since the various metal parts will be the same after the seal is replaced it should give the same pinion shaft tension as before it was disassembled. If you took it apart without marking it you're in a bind.

-

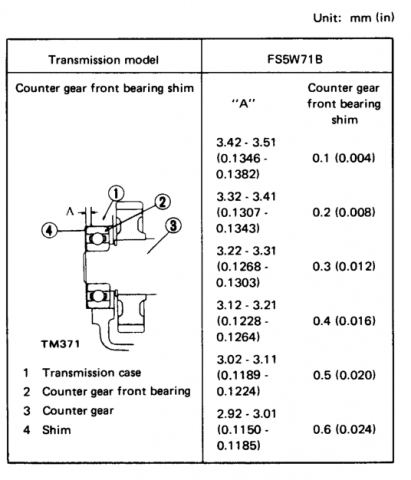

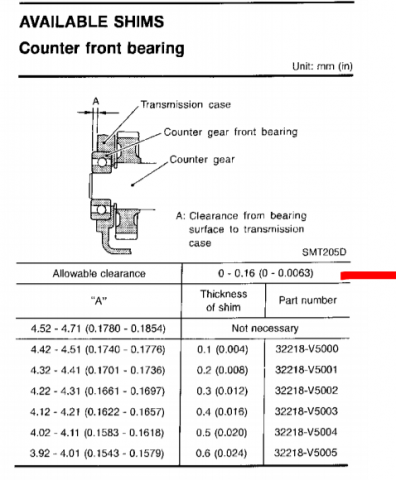

I meant thicker shim above, not thinner. Sounds like you're on it anyway. Good luck.

-

If I recall right the shim contacts the bearing and the A dimension is how far the bearing sticks out. You're not shimming the cover, creating a gap, your shimming the bearing race to get a certain force. So the shim is meant to apply force to the bearing race, to keep it in place after expansion of the case. So, in your situation, you'd have a little extra force on the bearing race because your bearing is sticking out a bit far. Maybe give it a few more taps and see if it drives in farther. Might solve the dilemma. Otherwise, I think you'd actually want a thicker gasket. But that might affect your other dimensions. I've read that the racers often run a thinner shim to get more force on the counter bearing, to keep it in place when the transmission is really hot and expanded. Food for thought. That's how I remember things from back when I put one together. I could be completely wrong in my thinking. I also have a book on rebuilding transmissions and seem to remember some good info there too. From 82 ZX...

-

It might help you to read the early 280Z and 280ZX transmission chapters. I think that they have a different procedure but for the same purpose. I remember thinking that the purpose of the shim was to apply some preload to the bearing. The Z and ZX procedure seemed to make more sense. Hard to tell what the 240SX procedure means by "allowable clearance 0 - 0.16mm". They mixed the directions in their table, I think, and are using the word clearance instead of tolerance. Confusing.

-

Brake booster/master cylinder options on a 73' 240z?

NewZed replied to a topic in Brakes, Wheels, Suspension and Chassis

Did you check the rod position? You'd think it would be centered between the studs but I think that some aren't. -

Download the first book here, the 1980 EFI Manual. It covers all years through 1980. Go to electrical tests and do the tests at the ECU connector as shown. Good luck. Power on both pins is normal if you test one connector at a time and others are plugged in. It's a parallel circuit, power comes from the dropping resistors. http://www.xenonzcar.com/s130/other.php

-

The injectors all open at the same time, so mixing injector connectors won't do anything. If you ONLY replaced injector connectors and this problem occurred then I'd say make sure that all of the injectors have power and are connected to the ECU. Both pins doing what they should do. Because all of the injectors open at the same time and because things are rich when cold, you might have cylinders running on fuel from neighboring cylinders. As it warms up and at higher RPM things will get lean which causes backfires and other problems. Check your injectors for power and continuity, at the ECU connector in the cabin.

-

If the flow is high won't the bubbles get pushed out? Never really understood the bleeding problems, in the high flow areas. That's whole point of the modification, to increase flow rate in certain areas. If flow rate can't push the air then it's not very high.

-

If you turn the speed up to 1.5. It's kind of watchable. Lots of simple advice, like how to drill a hole. Not so sure he really understands how the modification works. Pretty sure he's read this thread. Should have mentioned it - http://forums.hybridz.org/topic/59029-head-cooling-on-cylinder-5-solutions/ "Embroidered" marks...

-

There are a few threads out there about doing this. The key is engine management. You're only up to the simple part. Here's a good broad overview - http://forums.hybridz.org/topic/50208-the-ultimate-l28et-guidewhat-you-need-for-350whp/

-

Brake booster/master cylinder options on a 73' 240z?

NewZed replied to a topic in Brakes, Wheels, Suspension and Chassis

They'd probably let you measure it in the store. I've done that at OReilly. It's more interesting for them than just taking money. They're bored. -

72 240z 77 ignition 81 turbo motor Timing???

NewZed replied to ChrisDatsunz's topic in Ignition and Electrical

Then it's one of those "make it work" setups, using NA parts to run a turbo motor. No real Nissan guidance. Beware of detonation. -

72 240z 77 ignition 81 turbo motor Timing???

NewZed replied to ChrisDatsunz's topic in Ignition and Electrical

Does the turbo motor actually have the turbo? Or is it just a turbo motor running NA? Probably best to know what full mechanical advance is and set initial based on that. If you have 20 degrees of advance and set initial at 20 you'll be at 40 total. Which is too much. You can look at the weights or just rev the engine with the vacuum advance disconnected and watch timing. -

https://www.facebook.com/OneSixIndustries/

-

Seems like it should. Looks like a product new to market though. Never seen it before. You can trace it all the way back to a one product web site. Not sure how well it will work, it looks like a small 24-2 VR wheel inside the cap. Unusual design. https://zcardepot.com/distributor-crank-trigger-sensor-efi-240z-260z-280z-510 http://www.onesixindustries.com/products

-

It is low on power. And you still haven't told much about the engine. And you still have big injectors on a motor that has no need for them. Like you're not really sure what you're doing. Sorry. You'll have to learn the basics of how engines work. Especially these L series engines. It's all well documented on the site. Except for "W45 intake". Not clear what that is. Show that you have your cam on the right hole and the notch and groove are aligned. What's your compression ratio? Is valve lash properly adjusted? The basic starting points, before you even begin tuning. Your list of things doesn't mean a whole lot without the details. Somebody can probably look at your MS file and get you a few more HP. But there's a lot more to it than just a "tune". Good luck.

-

It's nice work. But the front mount has the same leverage problem that most of the short nose diff mounts have. The nose load has a short lever on the two body mount bolts. The back bolt is essentially a fulcrum, getting upward load under forward acceleration, and the front bolt gets a downward load.

-

Exhaust leaks often make a mechanical sounding ticking noise. Kind of sounds like the temperature rise has made you sensitive to all kinds of normal noises. Oil pressure will drop as temperature rises. Does coolant temperature still rise at higher RPM? If you don't have an HG leak in to the cooling system, your cooling system should have been able to maintain temperature. I'd fix your cooling system first. Sounds like it might need work.

-

100 HP is pretty bad. You don't mention a cam profile, or cam timing, or exhaust system, or compression ratio, or any head work, or much at all in the way of mechanical details. Looks like a stock engine, which typically gets about 130 - 150 HP, with bigger injectors. No point in the big injectors if you can't pull the air to use the fuel. The site just had a series of posts about how attention to the fine details will get you more than the typical 150. You're on the other side, working with few details. No offense, it's just the way it looks. The tune can only maximize to the limits of the mechanical work.

-

I think that John Coffey had the high HP ITS engine. Search his old posts. Here's one example, but it doesn't describe the engine building just the results. He mentions 200 HP. But I remember reading some of his other posts. It is about attention to detail. Edit - also search just John Coffey and horsepower. Every now and then he would post his best bang for the buck list for creating power from a stock starting point.

-

So, the pistons aren't the "same" weight. What are you going to recommend?

-

Is there a question? Just curious. It's a Toyota engine?