NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

The idle speed change is a clue. Could be a big vacuum leak. A small leak raises idle speed, a bigger one drops it. A huge one kills the engine. Could be lash set too tight, or too loose. If you have an intake system vacuum gauge it's a good tool for comparing cylinders while running. The needle will jump. Overall though, all you did, hopefully, was adjust the gap between rocker arm pad and cam lobe. If you got all of the hoses connected correctly and the valve cover gasket placed properly it should be fine. The oil smell might be oil leaking from the valve cover. Who knows. There's nothing you can really screw up. I would retrace the steps you took and see if something's out of place.

-

I don't hear a knocking noise. If you didn't let the engine warm up you'll get a wet black deposit. Wet carbon is greasy feeling. You might be overthinking things, and nervous about your recent work. If you're sure got the lash aright, warm it up and drive it and see how it sound when it's hot.

-

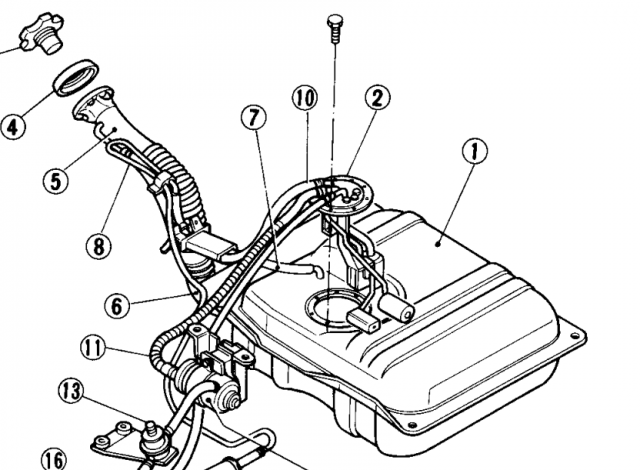

Need quick reference for fuel tank nipples.

NewZed replied to vleetv's topic in Gen III & IV Chevy V8Z Tech Board

-

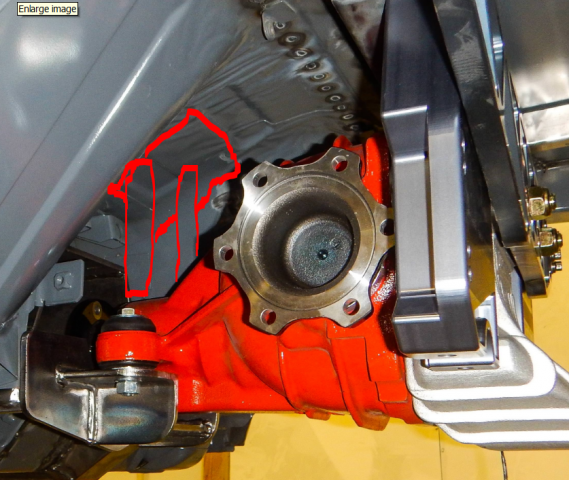

It's not really an adapter. It's an axle. Heat on the flange of the half-shaft. The part that needs to expand. But really, a big plastic hammer or even a piece of 2x4 will do it. Just grab a piece of wood, hold on to the axle (the new shiny part), and hit the half-shaft flange. It will pop right off.

-

Clutch pressure plate? Clutch slave cylinder issue?

NewZed replied to tamo3's topic in S30 Series - 240z, 260z, 280z

It's not the collar alone that matters. It's the collar (or sleeve as Nissan calls it), and the pressure plate. Together. Start at #35 here and it will make more sense. Maybe. https://www.classiczcars.com/forums/topic/44389-l28-is-toasting-my-240z-clutch/?page=2 Here's another interesting one - -

Hard plastic hammer, block of wood...the part that's sticking is just a press fit. Use a heat gun instead of torch if you don't want to burn your paint.

-

Necroposting to a Level 10 Necroposter. Apropos. Maybe the @ thing will work @jeffp

-

su carburetor 100% New SU Carburetors for Our Z's

NewZed replied to RoundtopsCarbs's topic in Vendor's Forum

Why are you not posting on classiczcars.com? Hybridz is the site where people are most likely to remove their SU's and sell them.- 8 replies

-

- carburetor

- round tops

-

(and 3 more)

Tagged with:

-

Add any head skimming to the program. Are these guys building the engine for you or just doing machine work? A good shop should be able to lay out everything that they think they need to do, before they even start. Piecemeal from the internet doesn't seem very quick.

-

Points or electronic? Pictures?

-

They should be able to estimate the depth with some simple measurements. If it's just some pitting next to a water passage you could probably seal it with JB Weld. Don't conflate coolant pressure with cylinder pressure. Pictures would be neat. Might get some better advice. Edit - not that advice so far isn't good. Just more of it.

-

WTB: 82-83 280zx Turbo Distributor/Distributor Drive Shaft

NewZed replied to heeblehob's topic in Parts Wanted

These guys probably have what you're looking for. http://www.zspecialties.com/ https://zcardepot.com/oil-pump-drive-spindle-oem-280zx-turbo-81-83.html -

Just Picked up an 84 Vette Motor

NewZed replied to Twisted46's topic in Gen I & II Chevy V8 Tech Board

Looks like you should have an L83. Things got weird in the 80's with lots of variation, I've never heard of some of the L's. Still, it's a standard early small block chevy. The JTR kit and book should work fine, I'd guess. Those extra pins on the alternator are probably for ECU diagnostics. Not necessary. Good luck. Even with the intake it's probably down on horsepower but probably still a torque monster. A diff and axle breaker. https://en.wikipedia.org/wiki/Chevrolet_small-block_engine#L83 -

ANOTHER Datsun Z/LS3/T56 Swap Thread

NewZed replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

Build a similar plate to the one you already have but put it directly over the mounting points. Run some pipe up the plate, or build a structure from more plate. You could even use threaded pipe portions for pinion angle adjustment. Or tie it in to the tunnel. Removes the leverage problem and clears up a lot of space. Looks like you have the fabrication skills. -

Maxima rear brakes and 280zx MC

NewZed replied to 383 260z's topic in Brakes, Wheels, Suspension and Chassis

First glance says that you have a bad MC. You'll get a firm pedal at first then the pedal drops when pressure blows fluid past a bad seal. The booster gives that extra force to blow the seal. Edit - I wrote something about how "new" reman's are often bad out of the box but it didn't get through for some reason. Weird. Anyway, there it is. "New" doesn't mean good. -

Does it even run? Do you have a place to work on it? Not really enough info to say if it's worth $500. If it takes another $1000 to make it a daily driver, keep looking for a $1500 car that runs. Add up the parts you'll have to buy just to get it going. The "seal" on the front brake is going to need a new caliper. A decent battery is $100. If the tires are shot, that's another $600. Looks like the tires don't even match. It might just be a parts car. If you can't take it for a test drive, don't buy it.

-

There's no this.

-

Maxima rear brakes and 280zx MC

NewZed replied to 383 260z's topic in Brakes, Wheels, Suspension and Chassis

It's very often the bleed valve orientation. A bad booster won't cause the pedal to go to the floor. You either have bad seals in the MC, air in the hydraulic lines, or a mechanical misadjustment. The standard test for air in the lines is to see if the pedal will "pump up". Pump the pedal quickly several times and see if the pedal gets higher. -

Brake booster/master cylinder options on a 73' 240z?

NewZed replied to a topic in Brakes, Wheels, Suspension and Chassis

Apparently the Tacoma is the closest North American variant. The HiLux isn't sold here. Might be worth a side-by-side comparison of the boosters. https://en.wikipedia.org/wiki/Toyota_Hilux Seventh generation (AN10, AN20, AN30; 2004–2015)[edit] The seventh generation Hilux (AN10/AN20/AN30), part of the IMV program, started production in Thailand during August 2004.[17] Three pickup truck body variants were initially produced: a two-door Single Cab (referred to by Toyota as IMV1), a two-door Xtra Cab (IMV2), and four-door Double Cab (IMV3).[26] In September 2008, Toyota released the Smart Cab, a four-door with hidden rear suicide doors.[27] The IMV program also spawned the Toyota Innova (AN40) minivan (IMV4) and Toyota Fortuner (AN50/AN60) SUV (IMV5).[17] The similar Toyota Tacoma pickup truck, introduced in February 2004 for the 2005 model year, is based on the 4Runner chassis, while the AN10/AN20/AN30 Hilux rides on an revamped version of the ladder frame found on previous versions. The Hilux increased in size and then became classified as a mid-size pick up. Hilux models sold in Asian, European, Middle Eastern, and Oceanian markets are built and assembled in Thailand. . -

Traction controll on a Carburated Car?

NewZed replied to Rusty Old Z's topic in Brakes, Wheels, Suspension and Chassis

You can use "slew rate" ignition timing control. It changes timing if the engine RPM accelerate too fast. Edit - to be clear, it uses rev-limiting, in whatever form that is. One example - https://www.hotrod.com/articles/msd-ignition-traction-control/ -

A slide hammer, a long bolt, and some SteelStik would probably do it. The insides are all greased up so you wouldn't have to worry about gluing anything to the crankshaft.

-

AZC says drive shafts aren't ready yet. But then their whole web site is from the 90's so who knows. Good luck. http://arizonazcar.com/strassy.html

-

The black one was mentioned in the link, as one of the three. Three show cars. Should be interesting to see how the pieces hold up to 200 mph. It's hard to tell how well built the cars really are. The odd "I'm a 240Z story" seems to have been copied to many sites, like somebody building a brand, but it's hard to read. I couldn't finish it. I think that it might have been famous in a small community for a short while. Good luck with making it a performance car. The Modern Motorsports package is probably the most effective bolt-in product. Already tested and proven. That's what you're paying for, hence the cost.

-

It's not done unless the charge is completely gone or you need "perfect".

-

Dang, screwed up my post.