NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

You changed at least two variables at the same time. Going back to #2 will move the power up the RPM curve. And you're tuning by ear and butt. You've lost the honk of the triples so it will sound less powerful, of course. Without numbers though, you're really just guessing, and any suggestions are mostly bench-racing. Unless they have numbers to compare. No offense intended to the prior suggesters but the comments seem to be about expectations, with no measurements. Also noticed this - "WOT AFR is very consistent ( beauty of MS).", and remembered that you want to be rich when you're around the torquey part of the power band. You didn't give the numbers though. So maybe there are still some tuning gains to be gained. How do your ignition timing advance curves compare? Another variable.

-

Getting rid of that rat smell

NewZed replied to theczechone's topic in S30 Series - 240z, 260z, 280z

Check any flat area where a mouse (not likely rats) can sit and pee and poop. They pee wherever they go so the pathways to the flat places are important also. I found about 1/4 inch of poop on top of the glove box in a parts car bought, and a nest in the blower for the AC system. Your main problem though is that they pee everywhere. So anywhere they went is everywhere they peed. -

The OBX is essentially a knock-off isn't it? Maybe you got a counterfeit knock-off.

-

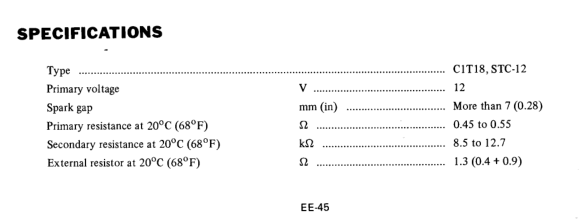

Just realized that you said reliable, not stronger. The stock 1975 coil's primary circuit resistance is apparently 0.45 to .055. So, just thatching that range would be the way to go to find a replacement. But it won't be more reliable, unless your old one is failing.

-

You edited the original post so it's not clear that you even asked a question. But here's an answer to your edited post. #1. My coil is a GM HEI coil. It has a primary circuit resistance of about 0.5 ohms (edit - changed from 0.8. Forgot about meter leads.). My ignition system is not the factory system. #2. Your first question is actually two questions in one so can not be answered. Plus you haven't given enough detail about the rest of the system. You said that you're getting "ignition components". Plural. But you only mentioned one coil. What are the other parts you're getting? Sorry. It's just not clear what you're trying to do, or planning to do. The 1975 system is an electronic ignition system but it's low power. Swapping to a different coil might get a stronger spark but will probably cause your ignition module to fail due to the higher current. The systems are old and failure prone, after all of these years, even in stock form. If you're planning a stronger ignition system there are many different ways you can go. Swapping the coil to a Pertronix coil isn't the way to do it.

-

Try starting fluid and see if it will start and run for a few seconds. Measure fuel pressure before pulling injectors. Fuel pumps can run in reverse, they're DC. Confirm fuel pressure, don't assume. Looks like you might have some good info from the previous time it started but you went all weird with the Star Wars comment. How long ago, what did you change between when it actually started, and now?

-

A quick FI and ignition 280zxt to S30 turbo swap guide

NewZed replied to bumble zee's topic in Turbo/Supercharger

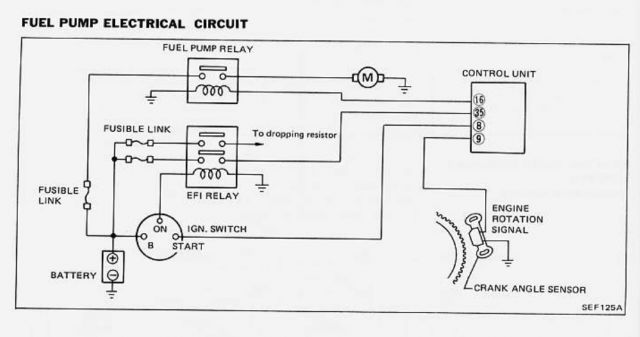

If you don't have the control relays, you'll need to come up with your own system. "M" is the fuel pump. -

A quick FI and ignition 280zxt to S30 turbo swap guide

NewZed replied to bumble zee's topic in Turbo/Supercharger

What do you want that wire to do? Power the pump? Ground the pump? You could look in the 1981 Nissan Service Manual. The EFEC chapter probably shows it. -

I've seen that in the past, but don't have it now. It seems to be malware on individual computers. I don't know about the solution provided in the link below but the description of what it is is good. Sometimes the malware fix downloads have their own malware. If you search around you might find a way to uninstall the malware yourself. I've had to do that after downloading free software. https://malwaretips.com/blogs/underlined-words-popup-ads-removal/

-

Finland - highly skilled designer/fabricator of Z project

NewZed replied to jhaag's topic in Non Tech Board

My mistake. Got my time spiral backward. -

Finland - highly skilled designer/fabricator of Z project

NewZed replied to jhaag's topic in Non Tech Board

I thought you were talking about the year of car. 1978 was the last year of the Z. Maybe you were talking about the year of your memory. That's a long time ago. -

Finland - highly skilled designer/fabricator of Z project

NewZed replied to jhaag's topic in Non Tech Board

So it was a 280ZX, not a Z? I notice that you have a ZX. That would be a big clue. -

Finland - highly skilled designer/fabricator of Z project

NewZed replied to jhaag's topic in Non Tech Board

How about some details of the car. 240Z, 260, 280? Engine? You provided "chopped top" but there must be more. Color? How and when did you get the information that you have? From Hybridz? Sorry, it's probably clear in your mind but you haven't really given many clues. Good luck. -

Finland - highly skilled designer/fabricator of Z project

NewZed replied to jhaag's topic in Non Tech Board

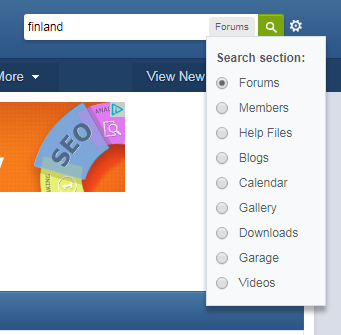

If you search the forums for "Finland" a few names come up. It doesn't work in the Members section, for some reason, but it does for Forums I'm going to guess it's this guy though - http://forums.hybridz.org/user/32042-boben/ You have to choose the area you want to search, in the drop-down by the Search box. Doesn't look like I can link my search term., it's probably in a Cookie. http://forums.hybridz.org/index.php?app=core&module=search&do=search&fromMainBar=1 Here's a picture - -

It depends on your engine management system. But you can run them on the Datsun EFI system without doing much, if anything. Some people don't even bypass the resistors. The Datsun 280Z system is primitive so any opening and closing time losses are tiny compared to the overall level of fine-tuning you can do.

-

Your stock 1975 has electronic ignition already and the specs are probably better than the Pertronix. Pertronix is old technology, it's not "high energy". You'd be going backwards. If you want a stronger spark you should change to a 1978 module or convert to a GM HEI module, or MSD or Crane. Besides that, I don't think that Pertronix makes a part for a 1975 280Z distributor.

-

Here's an 82. Looks like 19 degrees (edit - 17 like JM says below. I can't add) at 2800 RPM. But if it's a reman, who knows. Isn't that dip just an artifact from hitting the throttle to start the run? I drive my car around at 1500 to 3000 all day. Always bugs me that the dyno curves are always focused on the top end. Big numbers!

-

Questions for those that have put an STI R180 into a 280Z

NewZed replied to garcenw's topic in Drivetrain

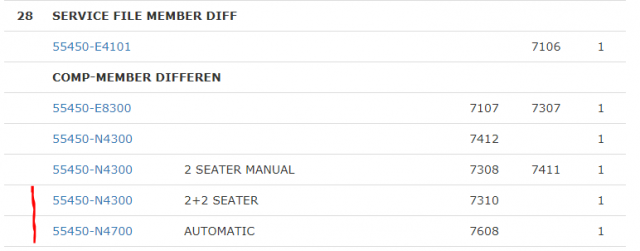

Don';t know why a car company would make two parts if they could just flip one and make it work. But, who knows. The bar and diff mount rubber are flexible enough that you can probably pry any combination parts around and get the bolts in. Half shaft angle will affect vibrations though. The automatic 280Z R180 bar is probably stronger and/or stiffer than the 240Z bar, to keep up with the heavier car and bigger engine, Seems like the best route. -

71 240z... need some guidance in my plans.

NewZed replied to RichardPosterior's topic in S30 Series - 240z, 260z, 280z

It's June 2017. Let's see how long this project takes. You need to decide if you want to boil tires or have traction. Mint-tubbing won't be necessary if you just want to make smoke. -

Questions for those that have put an STI R180 into a 280Z

NewZed replied to garcenw's topic in Drivetrain

Just came across this bar for sale - https://maseraticompound.com/products/datsun-240z-rear-transmission-mounting-cross-member -

The bip373 IS the ground wire for the coil. If you test the CAS by pulling it and spinning it by hand you can hear the injectors clicking, because there's no starter motor end engine noise. I've tested a CAS that way by plugging it in to my Pathfinder harness. Turn on the key and spin and you should hear them clicking. It's kind of cool.

-

Do you get injection? Might tell you if Megasqurt is at least using the CAS signal to get half the job done. You can remove the distributor and turn it be hand to listen for injectors clicking. You can also get another CAS, like from a junkyard, and plug it in and spin it by hand to see if you get spark.

-

280z Overheating at low speeds

NewZed replied to sugisan's topic in Trouble Shooting / General Engine

Seems like you're acting on maybes instead of figuring out the cause first. You can leave the hood half-latched to do an air evacuation experiment, before installing grommets or getting a vented hood. And why do they call it a splash shield? And if Chickenman is right about highway speeds how is it going to help your problem? Don't spend on random possibilities if there's still some simple things you can do to get closer to the true cause. -

Sounds like fun. If it hasn't been driven for a long time it might be a stuck valve, or ignition timing. If it's running might as well let it run and loosen up while you check the basics.