NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

That thread won't even open any more. Poor guy.

-

It must be just that one. The other threads seem to work. Never mind.

-

Except my own, apparently. Here's the one I can't reply to.

-

As in title. No way to reply.

-

cranks, but no start/ignition (video)

NewZed replied to SoFlaZ06's topic in S30 Series - 240z, 260z, 280z

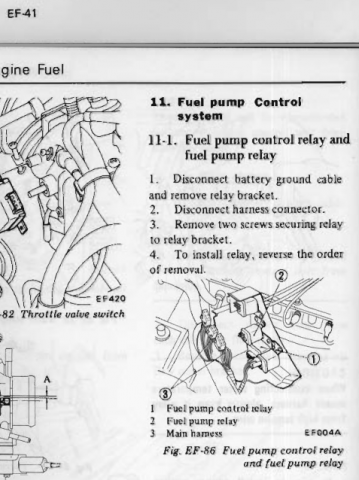

Nissan's FSM's grow from simple to complex. The farther you go the more they tell you. EF-41 shows where the relays are. And. of course, the next page from your schematic shows the test procedure. Edit - the relays are in the engine bay, by the battery. Nissan's pictures aren't the clearest. -

Trying to make a 280z daily drivable.

NewZed replied to harry1589's topic in S30 Series - 240z, 260z, 280z

1975 is the last year that doesn't require emissions checks in CA, apparently. So the degree of modification the PO did will determine how much work you need to do. It could be dirty or it could be in factory condition and clean. But the basic parts, like hoses and wires and plugs should be decent if it was drivable in January, you'd think. https://www.dmv.ca.gov/portal/dmv/?1dmy&urile=wcm:path:/dmv_content_en/dmv/vr/smogfaq#BM2536 -

Trying to make a 280z daily drivable.

NewZed replied to harry1589's topic in S30 Series - 240z, 260z, 280z

You're implying that the car was parked 40 years ago and has not been driven since. Has it been sitting? how long? Download the FSM and read up, especially the Engine Fuel chapter, and Engine Electrical. The engine has electronic ignition, not points. As far as changing things, it depends on what condition they're in. http://www.nicoclub.com/FSM/280z/ -

So, in short, you just bought a 1976 280Z? And had a baby. Congratulations. Edit - I see a lot of pent-up energy being released in that post...

-

cranks, but no start/ignition (video)

NewZed replied to SoFlaZ06's topic in S30 Series - 240z, 260z, 280z

You can get service manuals with schematics at nicoclub.com. Link below. 1978 has an odd fuel pump power circuit, with multiple relays. It's shown in the Engine Fuel chapter. The pump should get power at Start, and when the engine is running, but not at Run if the engine is not running. But your problem, since things seemed to work right, might be related to the Ignition Relay. A short maybe. It's schematic is shown in the Body Electrical chapter, with location, and in Engine Electrical too. Could also be that somebody mucked around with the wiring and it has failed. I'd figure out why Acc is powering the pump first, then figure out why Start is not. Good luck. http://www.nicoclub.com/FSM/280z/ -

It's probably the "other" 280ZX grind. Check the FSM's and you'll find specs for a USA grind and a Canada. Engine Mechancial chapter. For some reason they stopped listing specs in 1983, but the 80-82 chapters show them.

-

Unusually loud injector tick

NewZed replied to seattlejester's topic in Trouble Shooting / General Engine

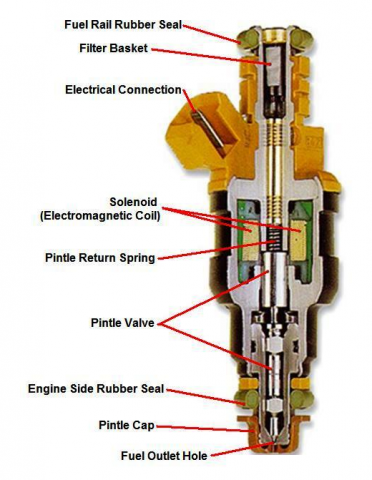

There's just a magnet and a spring. I don't think the pintle has any damping material, it's metal on metal. The magnet power comes from current and the spring is what it is. It could only generate more kick from more current. Maybe a short in the resistor for that injector only? Possible, if the resistor box has individual resistors. Measure resistance and see. Edit - actually, a broken spring could allow more kick. Seems like it would leak if that was the case. http://www.racecityinjector.com/fuel-injector-anatomy/ -

Suspension issue please help

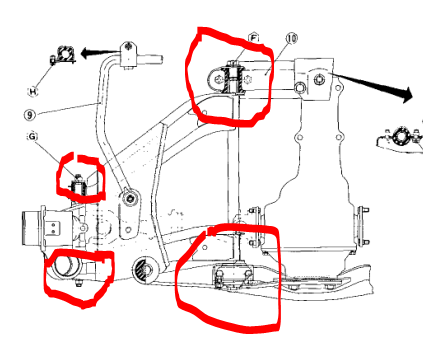

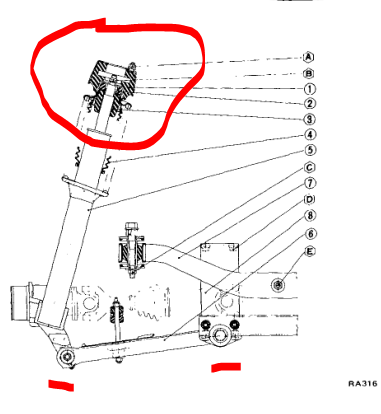

NewZed replied to JDs78's topic in Brakes, Wheels, Suspension and Chassis

-

Still seems non-ignition-related, unless the coil is overheating like steve260z suggested. If you can stop and let the engine cool off but still at operating temperature, and the problem comes back after 30 seconds, that doesn't really sound electrical. Bad fuel pump or clogged fuel lines come to mind. Can you confirm fuel flow and check float bowl levels when the problem happens? Seems like you've decided it's ignition but haven't checked the other stuff. You could get a 280Z distributor and a GM HEI module and have a better ignition system than that Pertronix unit, for about the same cost.

-

Those numbers look right. ~14.3 volts. Probably haven't fried anything. That voltage passes through the coil. Too high could damage it. But your numbers look fine. Could just be coincidence. When did you last change the points and condenser, and set gap or dwell? A condenser can overheat and short, causing ignition problems. Or your points might be burned. Give it a tuneup and see if there's a difference.`

-

Have you confirmed that the new alternator is regulating correctly? Could be that it's not and you fried something with high voltage. Easy to check with a meter at the battery. Even new parts can be bad. Or your S circuit might not be complete. Best confirm.

-

Why did you describe your new alternator and regulator-delete system? You're implying that they might be part of your problem. Did the ignition system work well before the alternator change? Has the engine ever run well? How do you know it's not a fuel problem? Did you know that some of the early cars have the electric fuel pump power supplied by the external regulator? Just adding some focus.

-

You're not clear. Ithink that you're saying the 280ZX axle won't work with a 240Z companion flange. Then a 280ZX u-joint halfshaft companion flange (with the 4 holes) along with the 280ZX axle should work. As shown in the link. Basically convert the 240Z axles and flange to a 280Zx axle and flange. Or that guy is completely wrong. Or the 280ZXT CV casting is a different size than the 280ZX NA casting. Edit - adding some bearing sizes just for fun. So, there's no good way, apparently, to use the 280ZX axles in a 240Z. I wonder if that guy just ran loose axles and didn't even know it. Scary. I'll have to stop referring to that page. ZX RW101 - 30mm inner, 62mm outer, 16mm width RW125 - 30mm inner, 72mm outer, 19mm width Z RW116 - 1.25" inner, 2.75" outer, 0.6875" width RW117 - 1.25" inner, 2.75" outer, 0.8661" width Metric Z RW116 - 31.75mm inner, 69.85mm outer, 17.46mm width RW117 - 31.75mm inner, 68.85mm outer, 22mm width From the zhome link - "To make a long story short, I found that the entire ZX Turbo shaft assembly from differential to and including the wheel bearing companion flange that slips over the splines at the wheel axle can be interchanged with the same Z parts. "

-

I think that all of the info needed is in the thread linked below. The castings are the same for 280ZXT or 280ZX (CV versus u-joint halfshaft), so the same swap should be possible, I would think. http://www.zhome.com/rnt/FordPower/HalfShaft.html Here's a Hybridz thread with bearing info. It has the same link in it - http://forums.hybridz.org/topic/103344-280zxt-stub-axle-cv-swap/

-

Rear Wheel Bearing Spacers

NewZed replied to itmstgofast's topic in Brakes, Wheels, Suspension and Chassis

Here's a good old thread. John Coffey describes some that he made (post #31) and 74_5.0L_Z describes some that he's about to make. http://forums.hybridz.org/topic/113462-rear-wheel-stub-axle-play-help-needed/page-2 -

A possible solution might be a 280ZX axle and flange. People use the 280ZX CV flange and axle in the 240Z hub so that they can run 280ZX CV shafts. The axles are 25 spline, they might be a direct swap, or you might have to swap bearings also, or bearings and companion flange. Not sure. And the dust shield probably won't work either. For some reason Nissan went from 25 spline to 27 spine then back to 25 spline.

-

High fuel pressure after fuel pump swap..

NewZed replied to ~KnuckleDuster~'s topic in Fuel Delivery

Seems like a person could set up a parallel system, with a second FPR back by the tank, set to a few pounds higher pressure. The fuel rail line would take only the flow it needed, as it needed it. On the other hand, a lower rate pump might work too. The reason the small return doesn't work is because the flow rate of the Walbro 255 is so high. I think my numbers below are right, the Walbro 255 will support 650 horsepower. Don't think that RB25 is making that. Just another view... 255 liters/hour = 4,250 cc/minute Punch in one injector and 650 horsepower target - https://www.rceng.com/technical.aspx -

High fuel pressure after fuel pump swap..

NewZed replied to ~KnuckleDuster~'s topic in Fuel Delivery

If you get your in and out backward on the FPR it will max out the pump pressure. Pushing on the wrong side of the FPR valve. -

Post a picture of the header ports. Usually, round port headers or exhaust manifolds will cut the corners off of the square port head exhaust ports. This can cause a major flow disruption in the gases exiting the head. That's your concern. The best way to tell is to stick a gasket on both sides and compare, to make sure the header flange holes don't block the head gases. People run square port headers on round port heads often. So you need to know what kind of header you have.

-

So how long are the runners in the SP manifold, and how long are stock? Besides the .040" overbore number, there's just not much that's been quantified. You don't have any numbers to work with.

-

There are really only three 280Z(X) manifold types. Are you talking about 280Z versus 280ZX? The webbed 280Z has the same runners as the non-webbed, I believe. 1978 versus 1976. What position is the cam sprocket at? There's only three holes. Besides the position of the power on the RPM curve, you also made less with the SP manifold. The premise of the manifold was supposed to be higher numbers overall, besides the shininess. Beside that, many did not fit right. How did you get yours to fit? Could be some misalignment of the runners. As you restart the development work, make sire you collect good precise information.