NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

The title of your thread should really be about why a person needs to collect information before they make changes. You're starting from scratch now and can't really draw any conclusions about the intake manifolds or engine combinations. You're really just talking about what you should have done.

-

So the engine has seized up twice? Might be the reason that car was in the junk yard. I'd spin the engine with the valve cover off and plugs out, using the starter, if it was mine. Less stress on the parts and you can hear any odd mechanical noises. You'll drip some oil down the side of the engine but the late model reduction starters don't spin the engine that fast so it's not so messy. Watch oil flow, listen for noises, get things lubed up.

-

Remove the valve cover and spin the motor with the starter, spark plugs out. If you see oil from the cam shaft lube holes you'll know that the oil pump is working. You'll want to do that before you remove it anyway, because if it's bad you'll need to replace it.

-

There's too much guessing going on. You can check the valve train for oil to see if the pump is pumping oil. The engine should never "lock up". Are you sure that the battery is not just dead from cranking? Did any fluids come out of the spark plug holes when you finally got it to spin? The pickup screen is not going to be so clogged that engine seizes from lack of lubrication. Get a friend who has a bit more experience with engines. You're getting stuck on super-simple stuff.

-

Will you be cranking up the fuel pressure? And running them at 100%? https://www.rceng.com/technical.aspx#Fuel_Injector_Worksheet_

-

Did you squirt the starting fluid in to the intake manifold or in to the air filter? It needs to go directly in to the intake manifold through one of the small vacuum ports.

-

Either the spark is not really strong enough, or your timing is off. You might have the firing order correct but maybe #1 is not in the right place. Many of these old engines have their oil pump drives incorrectly installed and plug wires adjusted to make it work, then when people do a tuneup they put them back to the way they should be, and they don't work anymore.

-

Your cylinder pressure numbers look okay for a turbo engine. They're consistent across all-six which is a better indicator than the actual number. Then engine does "turn over", but does not fire. Try starting fluid in the intake manifold. But check your spark plugs first to see if they're wet to be sure. If they're dry, the starting fluid should start the engine, but it might then die. Not enough fuel from the system. If they're wet you'll know to focus on too much fuel. Check as much as you can at the ECCS plug with a meter as cgsheen suggests. That will tell you if the CHTS is properly connected, HowlerMonkey's suggestion. Beside that, when you're done, your 310cc injectors will spray 17% too much fuel and the engine will run rich.

-

Largest engine able to go into 240/280z?

NewZed replied to Fatlady440's topic in Other V8Z Tech Board

You'd probably be one of two. BRAAP used to be a lot more active on the site. Don't know what he's doing now. You never know, he might respond to a message. http://forums.hybridz.org/topic/46198-a-mopared-datsun/ -

Is it a new engine? You might just be burning some oil, and the rings are not seated equally between all cylinders. I think he's talking about the fact that one looks lean, two look rich, and three look close to right. The heat range looks pretty good by the electrodes but they're covered with deposits of incomplete combustion, like if oil was being burned.

-

Alternators on different engine

NewZed replied to Chandler347's topic in Trouble Shooting / General Engine

Does not matter a bit. Alternators are simple electrical components that can be swapped on to any engine, as long as they're wired correctly. -

Rebuilt a "wide ratio" tranny using 5th gear from a "close ratio"

NewZed replied to tincup's topic in Drivetrain

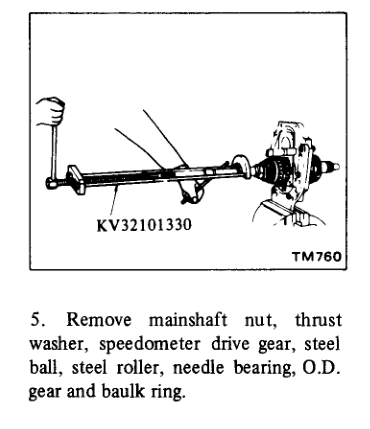

Looks like you have to disassemble the transmission to get the O.D. gear off the shaft. 1982 MT chapter.. And it's 80 - 83, not 79 - 83. 79 for sure and maybe early 80 are the "wide" ratio transmissions. -

Alternator upgrade after probable rewiring

NewZed replied to seiferzero's topic in Ignition and Electrical

Give an update when you get it installed. Many people convert a 90 amp Maxima alternator but you have to change the pulley, and reiwre the plug. An extra ten amps with just a plug rewire seems worthwhile and simple. It's been described before but doesn't seem that common.- 6 replies

-

- 1975 280z

- Alternator

-

(and 1 more)

Tagged with:

-

Alternator upgrade after probable rewiring

NewZed replied to seiferzero's topic in Ignition and Electrical

Looks a lot like a 300ZX alternator. 70 amps instead of 60. http://www.rockauto.com/en/catalog/nissan,1986,300zx,3.0l+v6,1209563,electrical,alternator+/+generator,2412 Take it to a parts store and make sure it's bad. Then see if it matches a 1986 300ZX. You might have to call ahead so that they can get one in for you to look at.- 6 replies

-

- 1975 280z

- Alternator

-

(and 1 more)

Tagged with:

-

Alternator upgrade after probable rewiring

NewZed replied to seiferzero's topic in Ignition and Electrical

Looks like somebody converted your externally regulated system to an internal system, with an alternator more modern than a 280ZX's. Maybe a Maxima or a GM alternator. Should be easy to switch the plug for a T plug, just figure out which wire is S and which is L. Might be easier overall though, to just replace the alternator with the same model that's in there now. But, if the car is new to you and the alternator has never worked, you might have wiring problems. Give a rundown on the car and why your'e replacing the alternator.- 6 replies

-

- 1975 280z

- Alternator

-

(and 1 more)

Tagged with:

-

Injectors making clicking noise?? PLZ HELP

NewZed replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Saw your post over on zcar.com and it's different. So that's going to cause you problems if things seem different in that short amount of time. One thing that can cause a "shorting out" electrical noise is the fuel pump contact switch in the AFM. As it starts to open due to low air flow the fuel pump relay will start chattering. But it's under the steering wheel in the cabin. If the injectors don't have power and only click once when you reconnect them that would mean that they're open and dumping fuel, if the pump is on. So that doesn't make sense. You've got some things that aren't factory stock so that adds to the difficulty. The fuel pump should not run when you turn the key On, and the digital tach you mentioned over on zcar could be part of the problem too. -

Nissan built new parts and had a Service Bulletin to fix a problem like that, on the first 240Z's. Can you get the picture any smaller?

-

Find the letters on the hubs first. If both sides have the same letter, then swapping the spacers wouldn't matter. In post #6 where i said give it a beating, I meant a few hard corners and miles, to warm things up and maybe reseat things. The way they designed that system the nut and washer on the axle are used as the press for the bearing race. So if things were tight initially on the races and their seats, even the high torque might not get them fully seated.

-

You might just go give it a good beating and retorque the nuts. Specially if the castings have the same letter.

-

The spacer matches the hub casting. So it could be different side-to-side if the hub castings are different. There's a letter stamped in to the casting that should match the letter on the spacer.. It's all described in detail in the Rear Axle chapter.

-

Did you measure the spacer and compare to the table in the FSM? And did you torque the nut to spec.? I've read that the spacers can get a bit crushed after miles of use. Nissan calls it a "distance piece" and it's matched to the hub casting.

-

Unidentified Suspension/Differential mount part

NewZed replied to Jeff9727's topic in S30 Series - 240z, 260z, 280z

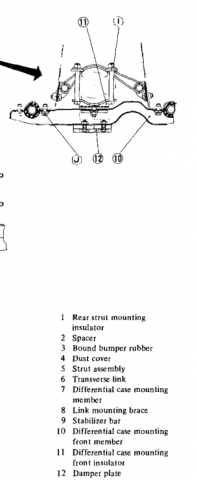

It's an anvil that Nissan provided with every car. It bolts to the bottom of the diff mount crossmember. Actually, it's a vibration damper. Many people remove them and never notice a difference. It is a handy weight and/or anvil to have in the shop though. Nissan doesn't mention it much in the FSM. I've only found one instance.- 2 replies

-

- differential

- r200

-

(and 2 more)

Tagged with:

-

madkaw's talking about the shape of the curve, less so the max number. Still no numbers. not even measured times, so it's all sensation. The same power curve with a bump at the top might feel less torquey than an engine with less max power. I remember getting beat by my friend on his boring old XL125, against my peaky two stroke 125. He had power everywhere, I had to wait on mine. Mine felt faster, but his was faster Plus he outweighed my by 20 lbs. Very frustrating.

-

At least he kept the scraps so he can undo it later. Part 2. The music isn't bad.

-

Swap your wheels front to back. See if there's a change. I had a broken belt in a tire that caused a vibration. Autocross is hard on tires. And rims if you hit something.