Search the Community

Showing results for tags 'timing'.

-

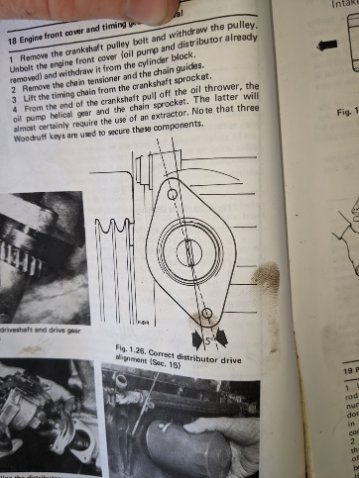

Good evening all, In the process of chasing down a high idle problem, and I decided to check everything was correct at TDC while I waited on some gaskets to come in. I have the car at TDC, on the compression stroke, both the valves in cylinder 1 are closed (I have the valve cover off to check them), my screwdriver is about halfway through the "lull" to tell me the #1 piston is at it's highest point, and the timing arrow is pointing to the 0 degree mark. HOWEVER, the keyed shaft (forgive me, I believe it's from the oil pump) from the oil pump to the distributor looks like it's off ~11-13 degrees. There are 32 teeth on the oil pump shaft right? So 1 tooth off would be ~11.25 degrees? Going to take a look at it this week, but just wanted to show some pictures and see what you all thought. I took the picture, threw it into OnShape, and then threw in the 5 degree line that the FSM calls out as what we're looking for. Thanks!

-

Hey everyone, recently swapped in an L28ET into my 78 280Z that is currently installed as an NA until my megasquirt is ready. Im running into a strange timing issue. My oil pump is installed properly with the shaft pointing to the top distributor bolt hole, my cam sprocket is set properly per service manual, wires are plugged into the distributor cap in the correct firing order, engine set to top dead center on the first cylinder and the timing marks lined up on the crank pulley. When i run the timing light i have to turn the distributor cap so far counter clockwise that the cap is no longer in the adjustment bracket when i have it set to 10 degrees. If timing by ear and what the car runs well at, im at about 30 degrees. I know its a bit premature, i dont have any photos ready for this yet but i was hoping someone may have some insight as to what could be a potential area as to why my timing shows SO far off.

-

I while back I took my car, (280z) to a dyno the result, (discussed in separate thread,http://forums.hybridz.org/topic/127636-thoughts-on-my-dyno-result-280z-triple-webers/?hl=%2Bdyno+%2Bresult I contined the investigation regarding the strange figures. I surely have jetting isusue, I however also discovered that my cam was way to retarded. After several measurements with degree wheel and indicator clock I decided to move the cam one notch forward. After this the measurements look quit ok, would probably be a even better with adjustable cam sprocket After advancing the cam these are the figures i got. Max lift intake lobe at 105 degres, approx 12,3 mm, defined max lift according to cam card 12,57 mm at 104 degreess Max lift Exhaust at 111 degrees, approx 12,3 mm, defined max lift according to cam card 12,57 mm at 108 degreess Intake lift at overlap 4,5mm Exhaust lift at overlap 3,5mm Below are figures I measured when camshaft mounted in engine. At 0,05 inch. Exhaust opens 65 degree BBDC Exhaust closes 17 degree ATDC. Intake opens 27 degree BTDC Intake closes 51 degree ABDC Overlap 44 degrees Overlap according to cam card 32 degrees The Duration I get with measured figures Intake 258 degrees Exhaust 262 degrees. Figures according to the cam card. Exhaust opens 50 degrees BBDC Exhaust closes 14 degrees ATDC Intake opens 18 degrees BTDC Intake closes 46 degrees ABDC Duration according to cam card. Intake 244 Exhaust 244 What I don´t understand is the differences in Duration and overlap when comparing to the cam card, this is very strange to me. I´m measuring this with valve play at 0,08 inch as stated in cam card and at the valve retainer. There are certainly some degrees here and there that are incorrect, but as whole I think this is correct. The big picture is showing a quit a big difference in Duration and overlap. I´m I missing something when measuring? The feedback I get from supplier are more aiming towards that the Max lift should be at the correct timing, and not focus on Duration and Overlap. For me this is a bit strange, I would like to know the actual Duration and overlap of the cam in the car. Grateful for any help. /Henrik

-

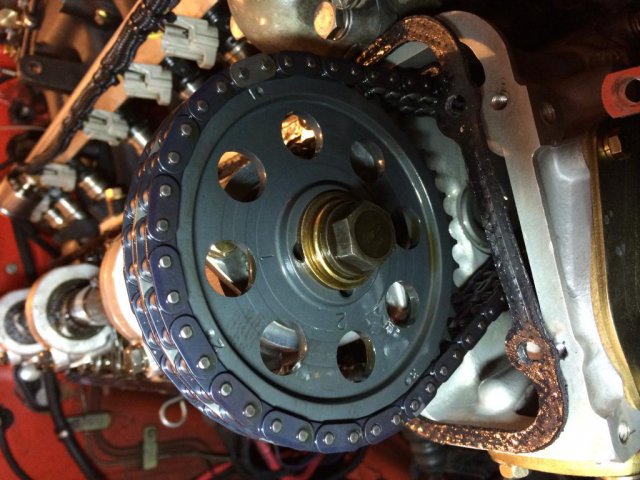

I´m right now on the final stage of my complete engine rebuild. Before engine start I´m double checking the timing alignment. I however seem to miss the V shape mark on the sprocket(aftermarket OSK) which makes me a bit hesitant. Below pictures show the alignment as i sits right now, can anyone please feedback whether it´s aligned or not. Car is a 280z -75. Chain, cam and sprocket are new and the the marking down at the crank is aligned.

-

Hello, Can anyone smarter than me take a look at this tune and tell me what is wrong with it for my build. I have a pretty much stock 82 l28et stock injectors DIY wiring harness i put together. iac sensor 240sx 65mm throttle body and tps DIY trigger wheel single coil lc2 wideband (not wired to ms2) walbro 255 lph inline fuel pump no other sensors are connected to the MS2 Ive been messing around with some other peoples tunes and came up with this. This started the previously warm car yesterday and i set my timing on the car with this project. its set to around 19 btdc because it was running so rough. The car was running very rich and was backfiring with every change in throttle. i assume the ignition settings might be wrong and the fuel map is too rich. ive scaled down the fuel map and it didnt seem to change much at all. could their possibly be other more hidden settings that i also have to change. Today i tried to start it and it just kept flooding itself no matter what spark settings i change or if i scale down the fuel map. Im new to this type of stuff so any help is apreciated. ive been researching so much and tried so many things but nothing is working. thankyou.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

My motor has always had a lite bit of a rattle but it has gotten worse to the point it scares me. Noise comes from the top of the front cover. Car runs great. Does this soundick like an upper guide or the lower tensioner?

-

Edit - First, thank you for any replies and to anyone who read my original post. I am learning this with the FSM and two repair manuals. I used a second set of eyes to go out and triple-check that I hadn't made a bunch of mistakes. The first cylinder gets a compression reading on the gauge at about the 45 mark (if it existed). When bringing the pulley mark to zero with the help from my second eyes, I get a completely different and much less dramatic looking scenario. The timing mark on the chain is a V (sitting at 2) versus a shiny which I couldn't find before. This looks less problematic than the crazy scenario I originally posted about but is still puzzling to me as the PO's mechanic didn't work on the timing but said there was a definite issue. Do these markings look off to you?

-

I'll stick this here knowing the subject has probably been beat to death already. Recently rebuilt mikuni 44phh carbs and added a Schneider 270-80f cam to E88 head, 2.6l block. Fuel pressure is at 3.5psi. The car started a little rough with a lot of backfire through the carb. I thought of the dizzy being 180 out but confirmed it wasn't. I have start to play around with advancing the timing. Initially it was idling at 0deg and rough, 2-3000rpm would hit 15-18deg and smooth out the roughness. Fuel pressure is at 3.5psi. I currently have the: Mikuni pilot screws are all out 1.5 turns. Idle sitting 1000rpm 15 advance at idle 2-3000rpm advance is probably at 30deg (off the scale) Still getting backfire through carbs particularly on cylinder 1 at idle. Next steps tonight are too sync the carbs, adjust with the idle on backfiring carbs - am I missing anything? I've attached an idle video and picture of jet sizes. Any input or comments would be helpful.

-

Hello all. So I recently picked up a new 1976 280Z Non CA. It has a few mods to it. Stage III schneider cam, headers, monza exhaust. Something failed on the EFI and the previous owner cracked open the AFM and tweaked a bit. This is causing the engine to run extremely rich. The coolant temp sensor is dead also. I've decided after seeing many split wires and splicing that it would be best to start new with Megasquirt. I plan on purchasing the MS2 3.57 assembled unit and wiring harness. I know this question strays from the normal. I know the option of going to a 82-83 dizzy. As of right now, I just plan on running MS2 for fuel only. I know there is a trigger input that comes into the ECU like the stock setup. Is this acceptable for the MS2 or can I not use this. My understanding is that the injectors fire on every third pulse. Looking through wiring diagrams I put together this diagram. The 1976 datsun looks like it uses a dual coil setup with a transistor ignition box. Can I still have the megasquirt hooked up with this setup or will it not like it? Any advice would be greatly beneficial.

-

Hello fellow Z Enthusiasts, I'm at my whits end here from this Darn Datsun. I've got a 1983 Datsun Maxima, and I can't for the life of me figure out how to get this thing running properly. A-little backstory on the car; The car used to belong to my grandfather, and when he passed away my father inherited it and drove this old girl everyday for 5 years to work, All the way up until the point the engine slipped its timing gear, then it sat for another 7 years until I was old enough to understand cars and not hurt myself while working in the garage. After purchasing a new timing chain and replacing the old one, the car ran fine. Well, my brother was using the car while his was in the shop during this last summer, but the dummy doesn't know a THING about cars and never checked the oil, water/coolant level, etc.; pretty much everything that you need to check on old cars to make sure they dont explode while driving them. Well, this time he didn't check the water level, called my father asking "why it was overheating all the time". And as he was driving it back to our house, the poor car blew the head gasket. Months of work down the drain (and wallet, mind you). It sat for another 2 months, until we managed to get the money to buy a new gasket. (Now THAT was one heck of a time, trying to figure out how to take the head off) We eventually got it replaced, but and hooked everything back up, but upon starting the engine we realized it wouldn't drive correctly. Let me explain; When you started the engine, it would idle great. It revved in idle like a dream as well. Then you'd try driving it; Ohhh boy, was there a problem. The thing would lurch and pop forward worse then a dang blender paired with a v8 engine runnin on 3 cylinders. Back to the garage I suppose. Everything looked fine, but we read in the manual that the oil pump timing gear needs to be 5 degrees past the time marks at 8degrees past TDC. Well, we were off, so we tried setting it how the book looked. Tried again. Cranked and backfired, and eventually got it started that way, but even then it ran so bad that it would die when you gave it just a tiny bit of gas. Back to the garage... We noticed that when we turned the distributer clockwise, it would run better, so we decided that instead of setting the Oil Pump Timing Gear at 5 degrees PAST the timing marks, we'd set it 5 degrees BEFORE the timing mark, still at 8 degrees TDC. Started it up, and amazingly it ran. It ran actually pretty good, which was surprising because it was the complete opposite of what the book called for. Our engine, a L24E non-Cali engine runs OUT of time, not IN time. But it was still out of time and not "drive able" (still lurched) and after hooking up a timing light to the engine, we discovered that the car would idle at 20 degrees, then drop down to 0 when you gave it gas, which would explain the lurching and backfiring. We thought we'd messed up on timing chain, so we checked that but it looks just like its supposed to. After a month of trying to time the car with the Oil Pump Timing Gear, we called 9 to 9 and Tom said that we needed to reset the computer. He said no matter what we did, the engine was fighting to put the engine back in time, so after a quick reset, we'd need to retime the engine again and it should be good. Well after resetting the computer and retiming the engine, the engine wouldn't even start this time. After fiddling with the Distributer and Timing Gear again, we got it running, and the engine now advances correctly when you give it gas. It no longer drops to 0, it goes up with the RPMs. We then tried driving it... Same thing again, only this time worse. It lurches so bad it could give you whiplash if you weren't careful. We think it may be a vacuum line, but they look hooked up correctly and we can't find any leaks, so we are literally going insane trying to figure out this engine. If anyone's been through the same problem or has an idea on what the problem might be, let me know what I could do to try and fix this. Thanks!

-

So I finished a rebuild of a 1982 280zx Engine recently and put 4-screw SU carbs on it and a stock exhaust manifold with 2 inch pipe and a turbo exhaust back so I can drive it daily with out waking up the neighbors. This is going to be pretty long so go ahead and ask questions and thanks for reading. Now to my problem/question: Driving now during break-in the engine makes a bothersome sound for daily driving that has not gone away in 200+ miles of driving. It has a very lopey and gurgle/burble exhaust and rev characteristic that sounds like a car with a cam that is way too hot for the application even though my cam is the stock grind. The idle is solid and does not jump around more than 100rpm on occasion and falls back to normal without dropping low after letting off the throttle. I fell like the carbs are well tuned and not the problem but I feel like the issue has something to do with timing and/or various tuning adjustments/gap settings of the car. I cannot for the life of me find a 280zx distributor with a working Vacuum advance so I've given up on trying to find a working VA and come to grips with losing the mpg saving that come from the Vacuum Advance mechanism. After tons of research I found info on using mechanical advance only and ended up buying a distributor on a recently wrecked running car that I pulled off and put on with very little rebuilding. 1st. I put it on and centered the Stator/reluctor inside, checked for basic function, set plug gap to 0.040", checked compression (all cylinders ~160), rechecked my hot valve gap and did some small adjustments to specs. Wired up the E12-80 module (tach still works, lucky me). Also cleaned the ztherapy carbs out and set to baseline for initial start up. 2nd. Then I set initial timing to 10 degrees BTDC and revved the engine to get mechanical advance all in (I messed up resetting the timing pretty badly at first and caused a few massive backfires, but corrected it quickly and nothing seemed damaged). I read 22 degrees of mechanical advance at 3500rpms which seemed higher than I would want for mechanical only advance. 3rd. I bumped initial timing to 15 degrees and got 37 degrees total at 3500rpms again and the car began to drive a better than when I had the pertronix and 240z distributor on the engine but it still seems to have a decent amount of noticeable engine/valvetrain noise and still doesn't have the free revving capability many people claim comes from the 280zx swap and from other Z cars I have driven in. Tuned in the carbs best I could with unisyn for the smoothest idle, the smoothest I got still seemed rougher than it should be, and got 22 inches of mecury at idle from a vacuum gauge at the balance tube. 4th. Checked the distributor advance reference spreadsheet for my model, D6K81-01 which should actually have 17 degrees centrifugal/mechanical advance at 2800rpms. If that is true than I should be able to go to at least 20 degrees initial which I think might be better for smoothing out the engine and driving feel. Should I trust my timing light here? I am new to timing and did tons of research before attempting it so do you think it is possible I may have used my dial on my timing light incorrectly causing the reading to be a bit off? 5th. I have most of the parts from 2 280zx distributors I tore down as well as the 240z distributor so I'm going to try and rebuild a distributor from parts while I use the current one to drive my car daily and continue to finish engine break-in. The new one I build will have no Vacuum advance either cause none of mine are in usable, the 240z vacuum dashpot had a medium fast leak that keeps getting worse over time so it's not reusable either. I also heard that many rebuilt dashpots have the wrong advance setting and can damage the engine if used, plus I'm sure every breaker plate I have has the broken plastic bearing run. I'm asking here on hybridz cause we have no reliable distributor shops in the area so I can't have it recurved by a professional so I'll do it myself and learn from the experience. How do you go about re-curving the mechanical advance yourself? Like where do did you get different springs for the weights and how do you do this slotting thing to lower the total amount of mechanical advance? From what I understand about timing, advance, VA, idle/cruise mixture, and off-idle mixture it seems like I would want about 23 degrees initial and 12 mechanical to when all in. I would like to know how that sounds to you smart ignition guys and here suggestions or examples of your recurves. Additionally I would like to here your thoughts on everything else I have mentioned that you think might be causing the odd driving and revving (e.g. plug gap, exhaust, etc...). Or if you think this is caused by a completely different issue than let me know, cause I have the original 4-speed that I did a mild overhaul on while out, but I have not done any work to differential or the hubs so something could be catching or clunking in there. I'm not very sure of the fuel delivery system (small leak from the Facet fuel pump and weird FPR, and no fuel rail or retunr line, but fuel pressure checked out) so I'm replacing that shortly anyway.

- 8 replies

-

- advance

- mechanical

-

(and 3 more)

Tagged with:

-

-

Hello all, I'm a long time lurker here and am having issues with my fresh (600miles) rebuild. The engine is an 83 L28ET, using MS1 V3.0 with spark control, Holset HE351 turbo, mild turbo regrind cam, forged pistons (~8.5 to 1 CR). I did a WOT throttle run to redline testing a higher boost setting while datalogging, near redline (6k in my case) the car sputtered, missed, and backfired badly. I got off the throttle, coasted to a stop, engine is dead. Cranked it back up, only ran while applying throttle. Still backfiring and sputtering, I pulled over and got the car towed home. Removed spark plugs, verified even compression in all cylinders ~120PSI. Verified static timing, verified fuel pressure, plugs are clean and not fouled. I had a helper start the car and hold the throttle while I watched with a timing gun - the car is now firing 1 at ~33 deg BTDC. I then checked the distributor shaft - it looks slightly off, but not a huge discrepancy. I then rotated the dizzy to "account" for the extra timing and get it back to 20 deg BTDC. Car idles without throttle input now, but is still running like a pig, stutters, doesn't want to rev, etc. I decided to not risk any possible damage and starting documenting everything. Valve cover is now off, I've attached pics of the cam position and the hash mark, the harmonic damper's position relative to TDC, and also a pic of the distributor rotor and the shaft tang below. After plenty of searching, the only thing I can come up with is the oil pump drive gear has slipped several degrees, but that doesn't account for why the car still runs bad even after i artificially fixed the timing by retarding the distributor position. My next step is brand new fresh plugs, perhaps a new fuel filter to eliminate that possibility (car is getting 35 PSI at idle, but who knows might not have enough to run more?) Any ideas guys? And I apologize in advance if I've overlooked anything obvious... I'm naturally very worried and easily may have skipped over something. Also, please let me know if you need me to take pictures of anything else. Thanks!

-

So i'm in the process of building my z and when I took the head off I was an idiot and didn't check to make sure the bottom end was timed and now that i'm timing the car I ran across a problem. The head and cam sprocket both have marks so that is in the correct timing position but the bottom end has no markings. The sprocket for the crank has a punch hole but there is nothing on the block to line it up with so now i'm kind of stuck. Any help would be appreciated. Thanks guys