All Activity

- Past hour

-

Ok, so heard a clicking sound which was at the same time your tach signal cut too (RPM needle dropping instantly). Is the clicking the fuel pump relay or something else? The tach signal is coming from the megasquirt ECM right? If yes then this is the power to the whole unit cutting on and off. Either from bad power/ground or faulty ECM.

- Today

-

Wow, so helpful.... Obviously, this is new to me, and I'm working through it all on my own, besides the posts I've made where people were actually supportive and helpful. If you've even tried to read what my messages say and my other posts involving megasquirt, you can find the information on both my status regarding car, wiring, and megasquirt knowledge. I literally said in the message right before yours that knew it was off and running rich. I've since adjusted my fuel ve table as to where I Idle around 13 AFR and ~12 cruising. Attached is my tune and an engine log. At the end of the log is where my fuel pump started to cut out. It seems to still happen randomly, I can't narrow down when it starts to cut as it does it when decelerating, at idle, or when on the throttle. Maybe somebody can simply help look at my tables and offer some guidance. The car runs fairly good and smooth, so I don't think my tables are "way off". I can't blip the throttle at idle to rev or to downshift, the car just seems to sputter, so I know my tables need tuning, but they aren't undrivable. My main issue is this mystery fuel pump cut. Don't bother to waste my time if you have nothing to say. engine log 1.csv CurrentTune.msq Fuel pump cut.mp4

-

Early 1974 260z build

juggernautjoee replied to juggernautjoee's topic in S30 Series - 240z, 260z, 280z

Literally just needed to change one setting from rising edge to falling edge and we're good. Had to find another tooth angle after the change, but that's easy to do. The AEM wideband was fixed by just grounding the brown wire. Drove it down the road a bit and let the auto-tune hit some target AFR's. It's definitely running better. I've just got it using wastegate pressure for now. I can hear it spool and release, so the BOV and all that stuff are working fine. I noticed I'm sitting at 60-65kpa at idle. I know my Schneider stage II cam is probably the culprit. I also need to do a hot lash of the valves, as they're a bit noisy. Hopefully i don't have a vacuum leak' -

Has anyone identified a 1/8th NPT temp sender that will work with the stock 280Z temp gauge? I tried the one below from Amazon but it just shot past 250 deg as soon as it registered. Zcar depot has one but it looks a lot like this Amazon one. I have an aftermarket thermostat housing and am already using the 3/8 npt port for a MS3 sensor. thx!! https://www.amazon.com/gp/aw/d/B085QBP6HR?psc=1&ref=ppx_pop_mob_b_asin_title

-

Chinese .63 A/R t04E with the billet compressor wheel. https://www.ebay.com/itm/174278894818

-

Sweet, looking forward to seeing how this goes! The powertrain is begging for a 3.9 or 4.10 rear but that's easy enough to change whenever.

-

What turbo are you running?

- Yesterday

-

Got everything tuned up a few months back, the car runs great, the power feels like its strongly in the 300s, but I can see that the cylinder head is holding the motor back. Quite sure there is detonation, as my computer keeps thinking there is, and the power is not really increasing at all above about 14psi. I think I will add a flex fuel sensor and try adding some e30 or something. I don't have enough injector to go very high on the ethanol content. Then again, it is quick enough as is. All in all I'm pretty impressed in how much this motor woke up with this setup, the turbo spools so quick that even off idle it feels like a much bigger motor.

-

Thx. I will check out classic. No chance on original engine her father had the car for some 20 years and he got it that way.

-

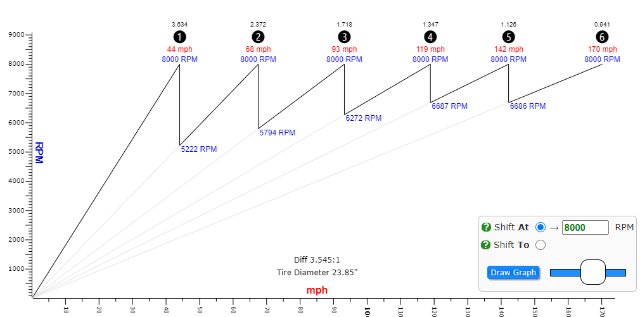

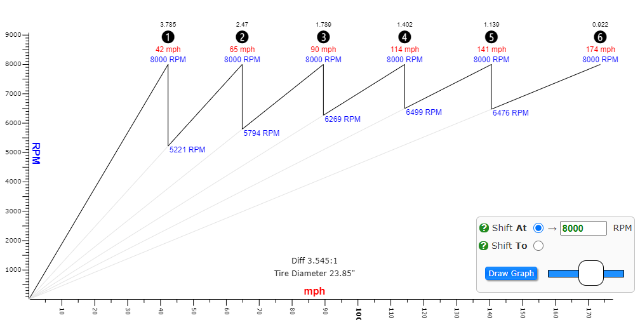

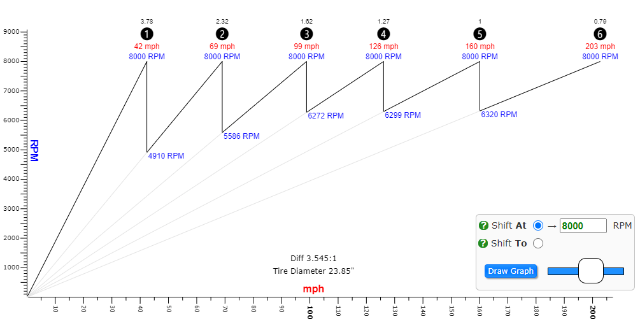

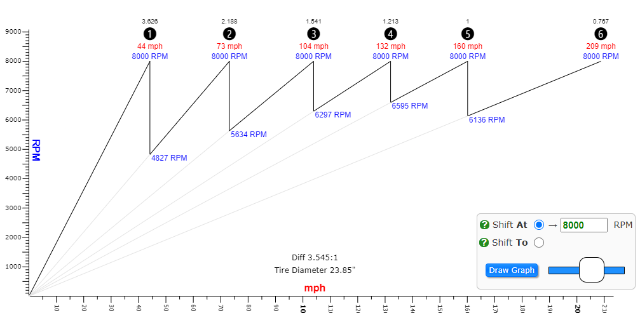

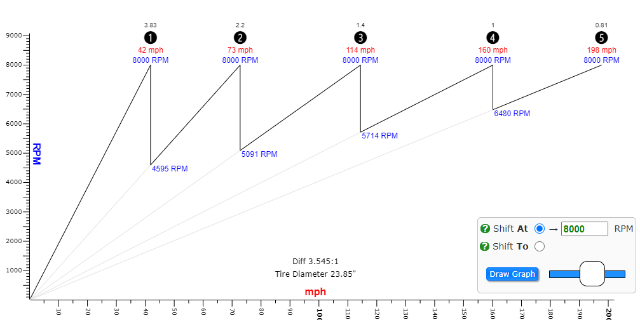

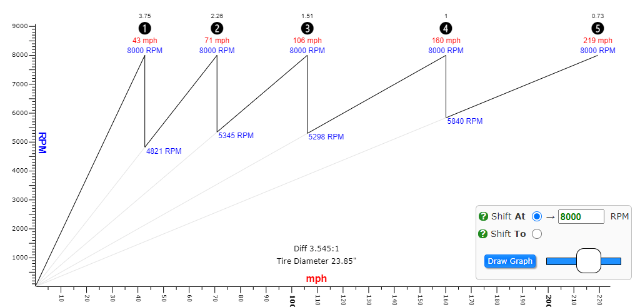

Yeah, I've never been a huge fan of 4 cylinders in a S30. It's one of those "sure, it's okay for you, but it's not for me" kind of things. But the K series is definitely more interesting the more I learn about it. My trans I picked up is definitely an AP1, and I'm aware they're slightly less desirable than the AP2, I haven't found any good indication that they're weaker. (note the 'AP1' as the 4-6 characters) AP1 bellhousing with internal slave cylinder conversion (will likely try to source parts to convert back to external slave) As for placement, yes it's a long transmission, but the design would lend itself decently well to modification if necessary, as the shift rod is of a single rod design and already travels a long distance to the interface with the forks. That said, it's looking like it will work "as is" for at least a first iteration: The engine might sit further back than this, but probably not much. Which puts the shifter here: If I put the tranmission back to where that shifter is just touching the back edge, then the bellhousing face is definitely behind the plane of the firewall. So I think it'll work without fuss. And for those playing at home: AP1 Net ratios (has internal reduction) 3.634 2.372 1.718 1.347 1.126 0.941 AP2 Net ratios (same 1-4 but different 5-6 and reduction gears) 3.785 2.470 1.789 1.402 1.139 0.922 And with a 3.545 R200 on 23.85" tall wheels: AP1 AP2 You can see that 6th in particular sits quite a bit further out, increasing overall spread of the AP2, but the added reduction makes 1-4 end quite a bit sooner, while giving relatively identical RPM drops as the AP1. The AP1 by contrast, gives you slightly longer legs 1-4 but 5th and 6th stay a bit tighter with smaller RPM drops as compared to the AP2 for 5th and 6th. Either way, the fact both transmissions have internal gear reduction and yet are geared surprisingly narrow, makes this a good fit for a higher revving engine in a chassis that isn't running super high ratio differentials. In a perfect world I think I'd still opt for at least a 3.7 diff, if not maybe as high as a 4.10, but let's compare this to something like the CD009. CD009 Notice that the RPM drops between gears are much larger, and the overall spread is much wider. This would certainly work well for a VQ which has a much broader torque range and falls off a bit on the top end, yielding a wider HP curve. But for a K24 where you want to stay up on VTEC to have fun, the CD009 trans would suit something like a 4.44 final ratio much better. The BRZ/FRS transmission for reference, has a pretty sizable drop 1-2, but stays decently tight 2-5 and a big drop into 6th which is fantastic if you want to run a super high ratio diff but still want a good highway cruise RPM. BRZ/FRS Now, another common option for K series transmissions would be the BMW E30/E36/46 transmissions, so we might as well add those to the comparisons (since I have dozens of these transmission ratios saved anyway). The BMW 6 speed: The BMW (E30) 5 speed: The BMW (E36) 5 speed: The BMW E46 also had a 5 speed option for a bit, and is relatively close/similar to the E36 5 speed. The ZF 5 speeds all end with a 1:1 5th gear, which ends up being pretty awkward so the better suited option would be the ZF 6 speed, but even that one has an awkward "rising" spread shift, or gets tighter and tighter. This might be good for a lot of driving situations, but my goal is making a car that's fun on the street, as well as fun doing HPDE/Autox events. I want as narrow of a spready as I can get 1-3 if not as narrow as possible 1-4. To that end, the AP1 or AP2 are both stand out options. Also, just because, here's the AR5 Would suit a V8 torque range nicely... Shifting a 6500 drops you to 3900, 4300, 4300, 4700 rpms. Very wide 5 speed, with decently spaced gears, though maybe a slightly close 1-2 shift. Not so idea for something super high revving, but I can see why a lot of LS people use it.

-

Wow, quite the shakeup Nate! Is that an AP1 or an AP2 box? They've got different ratios and synchros. I think the S2k box is longer than the Nissan, curious where the engine will sit when the shifter is situated. While I'm not a proponent of 4-cylinders in Z's, the K20/S2k box is a sweet drivetrain combo. I've got a spare AP2 S2k motor/gearbox/ECU/wiring harness drop-in that I'm still trying to figure out what to do with it... my best idea so far is to drop it into a Merc 190E to make a faux 190E Evo. This idea is however is purely in my dreams, as I have no time for any of this . I commend your efforts! AP2 box is on the left, there's extra ribbing around the countershaft boss. Pic is from Billman250 of s2ki: https://www.s2ki.com/forums/s2000-under-hood-22/ap1-tranny-vs-ap2-tranny-931368/page2/

-

I used this stuff on mine about 10 years ago. The areas I patched still look great, only problem is the rest of the foam is 50 years old, so it eventually cracks in new and exciting places. If you're able to, get a dash from Hong Vu or one of the other ones supplying it so you don't have to go through pulling the dash again.

-

Well it works. But the firewall flexes too much, next I will try to mount to the pedal box which doesn’t flex at all. I also want to keep the arm movement on the same plane. Currently actuator is up and down and bell crank is left to right. IMG_2655.mov

-

Kttrucks joined the community

-

Those AFRs are both way off. Most of what your saying makes no sense, and if you don't see that yet you really need to read more of the docs of tuning and megasquirt. I'm pretty sure your just way off with your megasquirt tables.

-

re-mapping and live tuning L28ET 1982/83 S130 ECCS

stupid_fast replied to stupid_fast's topic in Other EMS

A couple updates here. On Rayapp2's 81 slicktop turbo, I was able to decode and map out the 1981 turbo ECUs, those definitions are now available. The big thing here is he swapped to 60lb injectors and I successfully recoded the stock ECU for correct fueling. Found the new K value and rescaled the TP load scales and its happy. That car has further running issues that need to be solved, including the o2 swinging way more than my car does during closed loop, but the coding did its part. During this process I found a couple issues with what I was doing before, the rom chips I was using, ect. On my car I found the limits of fueling reliability on the stock AFM, which is about 200whp using virtual dyno to measure so probably inaccurate, but it should be within 10% of a real number. The boost on my car is back down to stock until I finalize a solution to make the fueling reliable. Moates has gone out of business, so my ostrich emulator is now unsupported and all the documentation is gone which is annoying. I was able to get Tunerpro working with emulation without offsetting the files, so everything gets a little easier there. Exactly how far can we go with this system? I have an idea, but its a couple months away from being fully tested. - Last week

-

Amazing work! I definitely don't have the time and patience for this, at least not now, but maybe give it a decade or two when the kids are older and hopefully work is not so consuming. Reminds me of the absolutely entrancing my mechanics 240Z resto videos on YT. I salute the people who have taken the time to get this good at metalwork.

-

1978 280z GTO LS1 T56 TTT

christianmoller replied to socorob's topic in Gen III & IV Chevy V8Z Tech Board

Hello, You have done some great job👍, i have just started the journey. /Christian -

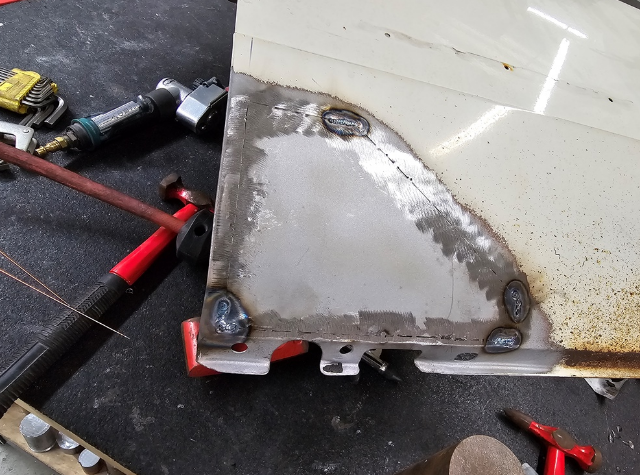

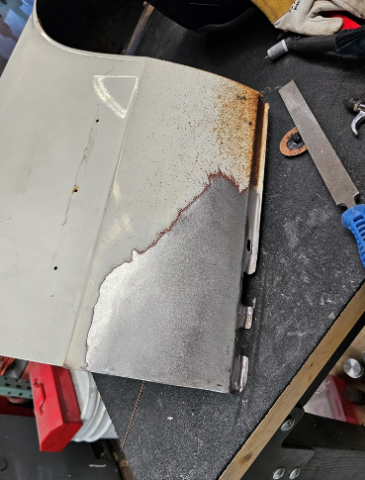

Then on to the front fender, Inner and lower. Another KF Fab part fitted in and TIG welded Cleaned up the weld beads and spot welded it back to the lower fender return Same deal on the lower fender. lots of small tack welds to keep it fron warping and small welds. I kept the original lower flange of the fender so the fit would not change. It cleaned up nicely with some blasting, and will keep the original fit and look of the fender For TIG the metal needs to be perfectly clean forpretty welds, but the overlap of the inner fender made this difficult, but they will look fine when ground back. A grinder, a file and a shrinking disk got it straight. A skim coat of filler will probably be needed to make it perfect as I cant get behing the repair to dolly it out perfect. The Hatch slam is up next

-

Here are pics of the front rocker panel and front fender work. All the same concept of only removing what was necessay and trying to keep it as original as possible with little to no filler. All original paint and never worked. Looks pretty good Whats hidden After blating with crushed glass Cut out the old, you can see the inside of the rocker was perfect and clean. the rust comes from the overlap of the inner fender and the front rocker. The cowl drain dumps back here and it just fills with wet dirt I bought a KF Fab full rocker and only used the small pc to repalce the area. The fit is really good on these parts TIG welded it back in. Carefully only 1/4" at a time jumping around with an air quench. Some quick grinding of the weld bead and it blends in perfect so it doesnt even look repaired.

-

Who's Online 6 Members, 0 Anonymous, 228 Guests (See full list)