-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

price check on 240z 133mm connecting rods with 9mm bolts

madkaw replied to cockerstar's topic in Price Check

Some how I am short one to make a complete set- so if anyone has an extra to sell please let me know -

List of Options for Crank and Cam Position Sensors

madkaw replied to cockerstar's topic in MegaSquirt

I think if the flywheel was drilled at a machine shop that could make exact depth and degree spacing that you might get away without balancing . Pro: more stable and probably more accurate signal -

Based on your skill level your budget is low , but don't let that stop you. Read until your eyes hurt and make good use of your budget. Don't shoot for HP goals - shoot for smaller goals like making your fuel system good enough for FI . Even with the "easy" zxt swap- there's a lot of ground to cover

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

madkaw replied to zredbaron's topic in Nissan L6 Forum

It takes a lot of time to put together a presentation - and a lot of work . Just share your findings when you can . It seems I have too many threads going on at once myself that I can't keep up with, but I try to share . Appreciate and always enjoyed reading your posts -

Thanks - that helps . I wired everything semi- and I'll upgrade to full seq. eventually .

-

Okay-still confused a bit on my sequential settings under required fuel. I am batch firing right now so squirts per engine cycle? Injector staging is simultaneous? Not sure why I can't get this straight, but don't think it is straight forward in tuner studio.

-

I have one of those bigger thermostats somewhere , but was trying to avoid using it with all its plumbing, but I might reconsider. I thought at the back of the head might be more accurate . I have a spare mn47 that I am cutting up so I might experiment with drilling it . Curious to see any possible casting issues in that spot as noted in other threads.

-

No input on the coolant temp sensor? Any input on the location of IAT? Finished wrapping wires today and about ready to start on fuel supply

-

Jack, FI is really the only answer for eventual pressurization . The change over is a good amount of work in the beginning , but in the end you will have a much friendlier engine to tune with an aftermarket ecu. Maybe your upgraded cam is all in at 5000 rpm because it was meant for a turbo engine. . Lots of guessing going on here - you really need some hard facts.

-

Got most everything wired up and in place. Most items are working but still need to place thermistor for the coolant. My coil brackets in the way of the OEM CHT. Thinking about drilling and tapping out coolant passage between 5&6. Its already marked for me on the mn47 head . Need to get connector for my cam sensor so I can get it installed. Probably run batch fire first to get engine running.

-

Got the injectors to fire in test mode to verify that I totally fuksed the firing order - fixed now:)

-

Okay guys-finally moving on to the fuel part of this install. Going with a N42 , 240sx TB and Bosch 26lb High impedance injectors. Just wiring up everything right now , no fuel pump hooked up yet. So my first question in this part of the install is settings in engine and sequential. Trying to get the required fuel number correct but the injector staging choices confuse me. I am NOT sequential (yet), but it doesn't really ask you that. So am I alternating with 2 squirts per engine cycle? My goal is to test my injectors to see if I wired them correctly. Might need help figuring what MS to put in for testing.

-

Eventually the coolant burning will kill your wideband too

-

I played with that calculator and it gives the L24 a deck height of -.100mm Which oddly enough is right after I shaved my block- lol

-

Not sure what you mean. See the pic above. I know you can't tell but I have room above my tank . My spare wheel tub is gone and the tank is framed in just below the floor. I probably have 1.5" of room or more. I am going to cut a hole in the floor for an access panel . I already have an access panel for the sending unit , and I will just make another for this pump. Maybe one could do something slick in the spare tub well to make clearance for the pump fittings.

-

I bought ONE aeromotive product -FPR- .cause I wanted to spend for quality there. The tank inc product was all I really found and it worked for me , so I stopped looking . 225$ for the whole kit with Walbro pump . You can't buy 1/2 of an Aeromotive pump for that. I'm not knocking their products , just don't want to spend 1K to convert to FI. I'm perfectly happy with rubber lines- HELL- OEM stuff is all rubber. OEM tank presents clearance issues that I don't have. Cutting and welding on a fuel tank gets into serious fab work. This would be better since it's just cutting a hole and dropping in.

-

And as far as all those components , I was going to move my battery in the back and use the battery tray for everything , HP pump, surge tank ...

-

I contemplated the aluminum , but listened to the critics I might regret it after trying to bend the stuff. I am going old school and skipping all the AN fancy fittings though. I'm going to try and install the new lines in the same place , but it will be fun . Just ordered FPR , SS fuel line and a bunch of fittings and still 250$ + . I figured the AN stuff would have been another 200$

-

I didn't want to make room or a place for a surge tank and this is a better deal for my set up for sure. Don't know if this would drop in a stock tank easy or not. This is the easy part - running new fuel lines will be a bitch

-

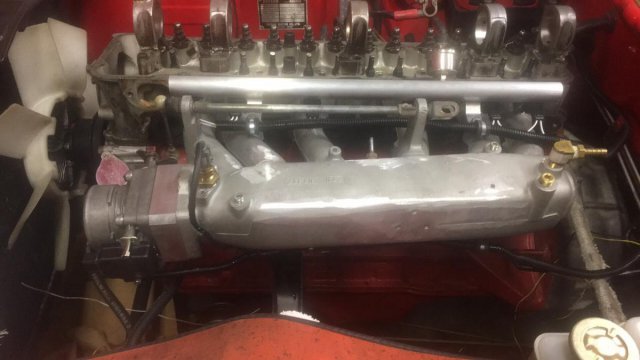

Thought I would document and take advice on this change over . Just sold off my triples and decided to get going on my MS controlled FI. First step - fuel delivery. My set up might or might not help anyone since I have a unique set up- CJ-5 poly tank . Going to use a Tank Inc drop in Walbro with sump. Just going to cut another hole in my tank and drop it in. Going to keep my original sender unit in there because it an accurate fuel gauge sender

-

I don't think you can make that blanket statement about deck height. I measured mine at .019 The OP could fatten things up in the prone areas of detonation with some more fuel. Beauty of MS. Non quench head makes for a challenge but there's enough success stories around . I'm going for 11:1 at least with 93 octane and a high quench head

-

Once again- different customer , different results . I am happy with my cam and it has held up well so far. Just surprised that after my ordeal my buddy also gets a bad cam card . Would you not be checking before selling the Datsun cams. I mean the numbers weren't even close.

-

Not sure there is all good things to say about Isky either. I got wrong numbers from them for my cam card . It took many calls to get right. Then my buddy ordered a similar cam from Isky - same ordeal but almost no support. I guess there's bad deals to be found everywhere . I plan on using a Rebello kit, but hope my outcome is better .

-

N42 has a higher nickel content too. Might consider having Rebello prep your block also unless you have a torque plate and a competent machine shop to clearance and machine it

-

Very impressive Tim- lots of time and money and patience . Was this an all out hp run or is this your DD tune?!