-

Posts

2281 -

Joined

-

Last visited

-

Days Won

15

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

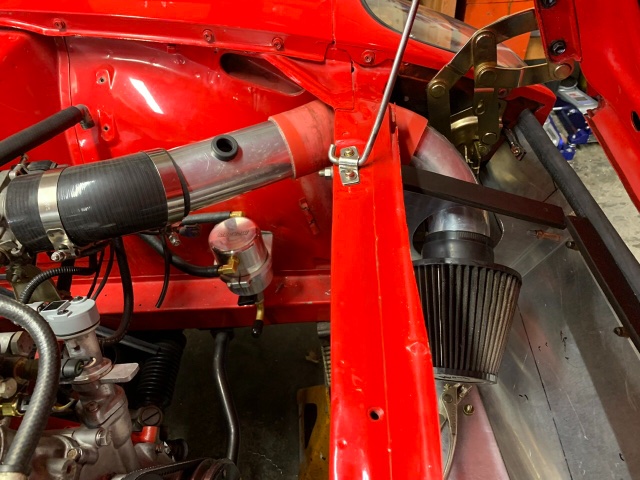

After reading up on intakes and airflow I might eventually need to narrow the angle on the top to keep the air flow from getting too turbulent . I guess the bigger issue is the post flow . It would be nice to come up with a slick exit strategy that doesn’t blow the hood up

-

Getting further along . Today I cut another hole - for the inlet . It seems small- maybe too small. I meant to make it 4” tall and it’s more like 3.25” . I also think where the fascia has landed I might actually be able to fasten the grill on top of it to keep it stick looking . I planned on blacking out the fascia to make it disappear in the background , but hard to say what it will look like once done . All I know is that no air is getting anywhere I don’t want - lol

-

-

Don’t want to alter the look of my car with a fiberglass hood , though a carbon fiber would be so much lighter . Ive been searching around for strut conversions . Don’t want to have to weld in mounts for the strut .

-

I think I’m not going to run the torsion bars on the hinges. Not only is it a PITA to around for, but they are weak to hold the hood up , and I cannot align my properly when they are installed- it aligns perfect with them off. The hood is a little heavy , but I’ll lift more weights . Next is the hole for the CIA pipe . Probably will mess this up at least once .

-

Transformed cardboard to aluminum! I’m pretty happy the way this is coming out overall . I think it will accomplish my goal to control the air in front of the car . Found some good seals on McMaster -car to help seal to the hood . Next fun task to integrate the torsion bars and CAI . I’ve been using these metal screws to hold things together and a lot of them will stay except the front panel which I will rivet before paint. Been tossing around where to put the inlet . Might go under the bumper with a 4”x 20” opening . like to hear some ideas I know my neck will be glad when I finish this project .

-

Someone update my status so I can post in classifieds please!

-

So are you saying the piston height is different from front to back? Can you rock the piston in the hole ? Stock spec piston height should be above deck .

-

Thank you - it does matter if I want to sound like I know what I am talking about - lol

-

I ran the clutch 3.90 before , but going torsion this time. I just bought a used ‘18 myself

-

Thanks Derek . Sounds like Subaru has been consistent .

-

Anyone have knowledge of more current years of diffs ??? I’m ready to purchase a torsion 3.54 . A ton on eBay as current as 2020 . They still look like the same casing but want to make sure my stub axles will work on any year .

-

Well this isn't about my Z , this is about my truck running ms2/3.57. Its a Z2.4 motor that I converted to MS. Everything was pretty good until the frigid temps came along . Anything under 30F and I don't get sync to start. It does light up green as I let off the starter(Which is a newly rebuilt unit) . I have a new battery , new ignition switch also. I am running the same CAS as on my car which is the Cherry Hall gear tooth sensor, running off my flywheel. I have 12v running to it. I have adjusted the pots to 2.5v as I have done before. I've done my best to keep sensor wires away from noise , but I read on the forums that the flash of green letting off the starter could mean noise from the starter. I tried to do a datalog of the tooth logger and forgot to save the file. I'll try it again tomorrow. I did put the battery on the charger overnight. Just trying to get some ideas on how to figure this out. I have a stim board but didn't think I could duplicate the issue on it. CurrentTune.msq

-

I recently bought both kinds . I couldn’t see a huge difference . I have precisions seals on my Z . The door in particular is just as bad on the both seals . Good luck finding Kia seals - maybe used . Some seals are only available at Vintage . I wanted the 1 piece hatch seal and only vintage had that

-

Made more progress on the fascia . I think my templates will help me think this out as far as sealing edges and the getting the best look . More than likely the grill won’t go back on. I think I want to bring the top of the fascia out a little , but not much . I need to cut a hole for my breather pipe . Need to find a place for the horns . I don’t plan on having any real framework since I will be using .125 sheet to fab everything .

-

It’s hardly far enough along to tell what I’m doing , but it will close off the compete grill area . All edges will be sealed with some kind of weatherstrip against the chassis .

-

Not sure I understand what you are saying. The grill opening will be completely blocked off except a small opening for the radiator . I will shooting to keep air from escaping anywhere around the fascia . all this to say, your idea is not bad but not optimal (if you care). If you do insist on keeping it narrow, I would put a slight angle inward on the sides. Sounds counterintuitive, but this creates a Venturi effect at slower speeds which will actually increase velocity into your rad. Angling outward will cause an eddy current on the sides of the rad support creating drag. Keeping a neutral angle (as you drew) will cause a thin surface to “flap” due to turbulent air flow at speed.

-

I’m only half done . The front grill area will be completely blocked off except a small opening in the radiator box .

-

Yep - I’m getting there . This is just the early stages of the project .

-

I had no idea what forum to post this in because it fits a lot of categories. I am modifying my from grill area to help with cooling and aerodynamics , which will affect the engine also. It’s kind of bodywork too , and some fab and welding . Anywho- here’s some pics of the start of the project . Making use of a huge box that my lawnmower came in to mock up . Goal is make this aerodynamic gain by blocking the air from getting in all the wrong places. Also getting air in the right places for cooling and better engine-temp control. At 75mph cruise I get some buffeting on the front end . I can see the hood doing a little shaking from the air getting under it . And if I get it looking clean I think it will good. Not really a sheet metal guy , but I can bend some aluminum around . I’ve been practicing with my TIG . I suck , but I’m hoping I can make some welds look pretty with some sandpaper-lol.

-

There is a forum for Megasquirt on this site - which would be a better place for this . I have a thread on there covering MS3x Install. It might help you . You can also put your tune on there to get help I’ll look at your tune tomorrow when I’m on my laptop . Make sure your tooth logger looks good and you don’t have any sync errors

-

There’s endless threads on this topic . I think you will want wider than 8” wheels to fill the ZG flares .

-

ZCarDepot Fan Shroud and Mishimoto 12" Fan?

madkaw replied to NorthStar's topic in S30 Series - 240z, 260z, 280z

I’m using the single fan they sell. So far so good with my stroker . I believe it’s a Mishuto also . -

Best option is z car garage axles -$$$$

-

So this isn’t a re-skin but replacing the complete roof and swap ?