-

Posts

1392 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by BLOZ UP

-

That initial flash should be the pulse. I don't understand what you are asking. If you tested at the injector and got a flash, that means they are getting pulsed. The only other thing I can think of is that if all your priming pulsewidths are zero, the fuel pump will also not come on for two seconds. But that would mean no pulse on start up. Which you said you had...

-

Who'd be interested if we made a L28ET trigger wheel?

BLOZ UP replied to Matt Cramer's topic in MegaSquirt

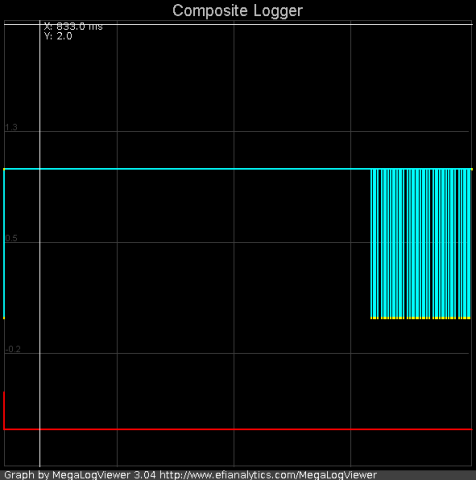

That was a 30 minute drive or so. Since then, I've enabled interrupt masking, and I think that has improved it. I also added some loom around the CAS harness. 20 minute drive produced no sync problems. But I will test some more to be sure. Now if I could only figure out my high req_fuel value, I'd be set. But "I digress..." Sorry about the messy thread, I thought it was related at first. -

Who'd be interested if we made a L28ET trigger wheel?

BLOZ UP replied to Matt Cramer's topic in MegaSquirt

I've tried the sync loss logger, I have two logs... I can't seem to get anything useful from them... I know I had multiple sync losses when logging. The screen changed, but I'm not sure what I'm looking at. I also tried the tach period rejection with liberal settings without much luck. Still got the sync losses. #2s and a #5 here and there. It looks like the #5s happen at various RPMs now, where the #2 is just in that 2200-2400 window. I've tried rerouting the CAS signal away from the plug wires. It now rests against the fuel rail and is closer to the injectors. sync2.csv.txt sync1.csv.txt syncloss.msl.txt -

For anyone whos really wanted to see a Z drift

BLOZ UP replied to Sideways's topic in Non Tech Board

It sounded like they had radios to keep tabs on traffic if any. But they need to work on their video editing. -

Looking to get an Optima Battery

BLOZ UP replied to Z lion 71's topic in S30 Series - 240z, 260z, 280z

No batteries I know of have a 10 year warranty. Most have 1, maybe 2 years. They pro-rate out to 5 years though. -

Cool! What's your boost threshold? Looks like 3k RPMS or a bit after.

-

Who'd be interested if we made a L28ET trigger wheel?

BLOZ UP replied to Matt Cramer's topic in MegaSquirt

I'm hoping the noise filtering will work. But what I meant was that the car ran fine when I tried it, no actual lost syncs. I'll have to drive it longer tomorrow. -

Who'd be interested if we made a L28ET trigger wheel?

BLOZ UP replied to Matt Cramer's topic in MegaSquirt

Tooth logger looked fine to me. Couldn't get it to mis-sync while logging, of course. But I should have thought to try noise filtering and report back. -

Who'd be interested if we made a L28ET trigger wheel?

BLOZ UP replied to Matt Cramer's topic in MegaSquirt

Also Sam280Z posted on the MSExtra forums about a similar issue: http://msextra.com/forums/viewtopic.php?f=131&t=43936 -

Who'd be interested if we made a L28ET trigger wheel?

BLOZ UP replied to Matt Cramer's topic in MegaSquirt

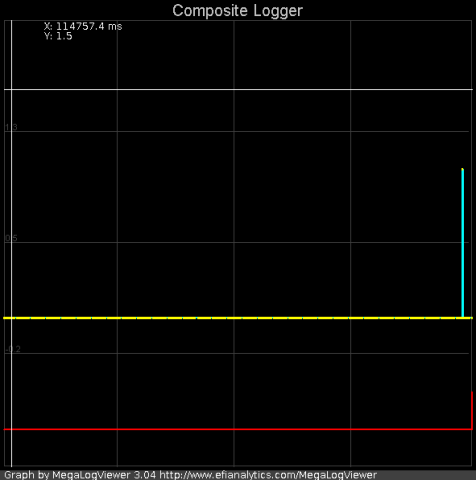

I'm having sync loss with the new wheel. VG30ET MS2 v3.0 + MS2-Extra 3.2.1 Single trigger w/DIY wheel single coil, distributed spark From my logs, it appears to be only between 2100-2400 RPM. The majority of sync loss reasons are #2 (missing tooth at wrong time), but there's also a few #5s (1st tooth failed test). Here are my wheel settings: Here's a couple screenshots: Attached is the log. You'll have to get rid of the .txt extension, unless MegaLogViewer is smart. datalog.msl.txt Watch out it's huge. An hour or so of driving. About 30 sync losses. I checked most of them, they were between the RPMs I listed. Diagnostics: I have it wired according the DIY article. I've got solid grounding and power to MS. However, my CAS wires do go near my plug wires. The plug wires are in good condition. The CAS wires are covered with loom (whatever EMI resistance that has, if any). I've tried routing them as well as I can. I have completely forgotten the wheel logger. I'll report back when I run it... -

I just got mine hooked up. I'd like to try and get one too. Maybe this weekend.

-

Are they brighter/better than OE replacement bulbs?

-

So I think I've got my car more or less working the way I want it. I would like to take some of the weight of my 1.25" SCH10 pipe, turbo, wastegate, and downpipe off of my exhaust manifold studs. I haven't had any problem yet, but I fear that one day I'll hit a bump and it'll snap all the studs and send my turbo into the ground. Hopefully this is in the right section. I figured either this or Exhaust/Fab. I couldn't find any other threads about this. I've seen some of the professional setups, they usually come off of the engine somehow. But I'm not seeing how I could do that here. Unless I'm missing something really obvious, which is not uncommon for me. I've added a heim joint and have a sort of idea of where I could easily support it.... except I don't know where I should support it from on the car. I have solid engine mounts. Here's an overview: If you look below, right in front of the paper towel stuffed in the compressor outlet, that's my "support": It's attached to the wastegate hole on the manifold, just covered by that coolant pipe's 90 degree silicone coupler. (In the first picture it's on the other side of the coolant pipe, laying against the radiator.) I just don't see how I can make anything go support that it without it looking stupid and being at an odd fulcrum. Should I move it somewhere else on the manifold? I figured I didn't want the heim getting too hot, or it might lose it's heim-ness. What If I got/made some sort of strut brace that also came to the radiator support?

-

I always pry on the housing of whatever it is. I figure that, a) it's not rotating, and it's wide enough to be able to have a nick on the outside. c) since it doesn't rotate, I can slap some silicone on it if there is a nick. So far so good. Most of the time I just use a small angled pick to go through the lip of the seal (around the crank/cam/whatever rotating part), grab the metal part from behind and yank it out.

-

That's olllld. From after the Texas Z party. You still haven't fixed it yet?

-

Isn't the rear main just at crankcase pressure? Why would high oil pressure cause the rear main to leak?

-

We sort of recently got a 08 GTI. Fun car.... but for only 38,000 miles... Interior rattles. Lots of them. Depends on the season which parts rattle. But it's annoying. Overhead lights are "quirky" and don't always go off or on with the "button" which is apparently connected to some sort of over-engineered circuit instead of just a switch. Very annoying metallic noise like something's loose on the LF wheel. I'm starting to think it's the strut mount/bearing. Don't think I'll ever get a VW. It's my wife's car.

-

Best swap for mid-engine balance

BLOZ UP replied to MazerRackham's topic in S30 Series - 240z, 260z, 280z

Single cam VG, easy. ZR8ED said it "changed the whole car" in terms of handling. I couldn't say because I've only just started driving it. And I didn't drive it with the L28 for very long. Puts the entire engine behind the rack. Not quite past the axle. Move the shifter back and it could go farther. It's a bit lighter than the L. Although with all these manifolds on it now... Dual cam, not so easy. I know someone's done it but I can't find any photos. -

They are pretty expensive maintenance wise too, I believe.

-

Collectors. I will never again try to make my own collectors. I like welding and all, and I guess I'm okay at it, but some things are just better left to people who's entire business revolves around making the parts, and who have large shops full of equipment to make them properly. Instead of a chop saw and a grinder. Ugh.... Never again....

-

Show pictures of your car repair related injuries

BLOZ UP replied to RebekahsZ's topic in Gen III & IV Chevy V8Z Tech Board

Burn scar on my upper leg where I planted the wrong end of a "just used" TIG rod in to my leg. Didn't feel anything for a couple moments, till it was down in the muscle. Worst was the compound fracture on my arm when I planted an SE-R into a telephone pole. But that's not quite during work on my car. Now I'm steel reinforced. -

Auto Z31s have the pot. You can tell by the seperate hanging harness off of them.

-

I feel that an RB would be less of a travesty than the VG I put in mine. But, I can swap back easily. Just need to pop it back in, add the engine side harness for MS and reflash it. Vroom. Anyway, do it!

-

I just had an "incident" with my crankcase system. I had mocked up some tubing for a catch can I am building, but to judge the lengths I just had the tubes connected both valve cover vents. Long story short, I noticed that there was an awful lot of smoke. Looked at the engine bay and oil was pouring out from behind the timing cover. Blew out an already (slow) leaking valve cover. Then I took my turbo back off to fix the seals. Intake pipes were coated with oil. Exhaust had oil dripping out of it. Apparently having PCV is necessary for these (non carbon seal) turbos to drain properly. So, I'm hoping once I have everything back together the seals aren't "toast".

-

How much power is actually needed?

BLOZ UP replied to vega's topic in Gen I & II Chevy V8 Tech Board

They don't have to. Knowing a car of X pounds goes however many feet in Y seconds requires, at a minimum, Z average horsepower (or integral, or whatever). It does assume perfect traction, etc. So it's a kind of best case scenario. Unless they give some kind of humanizing offset built in to the calculators. I wouldn't be surprised.