NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

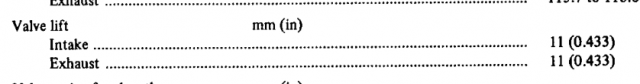

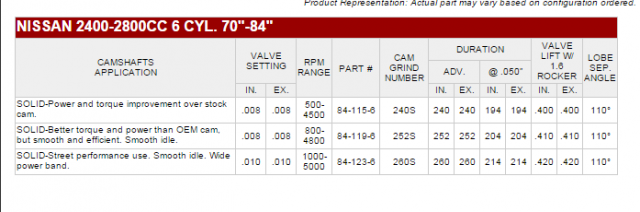

Something's off. The valve lifts are less than stock. Duration's longer for two, but they claim more power and torque with less lift and duration even for the first. How so? Not an expert, take a grain of salt. The guys that seem to know almost all recommend Iskenderian. A phone call and a discussion, gets a cam profile. Or you can go with a "Magnum". Awkward.

-

Post some pictures. Pick one project. Start working on it. Looks like nobody is going to offer to come over and help in person, so that's the next step if you want to make some progress. Or you can write more stuff on the internet.

-

Frankly, this looks like a quagmire. A big list of difficult things (flares, coilovers, and floor pans aren't that easy), not much many to spend, talk about "chopping" things up, with "lol" thrown in the mix. Probably best to offer free beer to anybody that will just stop by and check out your car. Give them a chance to see if they want to get involved. At least you didn't start with a giant HELP ME!. I hate seeing that.

-

https://www.facebook.com/South-Florida-Z-Car-Club-248039795221806/

-

Some people buy new clips, some re-use the old ones. They install inside the diff, not on the axles. Better read this thread from the beginning, there are some important posts about getting the parts right so that the clip grooves are the right distance in from the seals. So the axles ride in the correct place. Can't remember where, back in the #80-140 range of posts, maybe.

-

You're going to buy a whole distributor because a wire broke?

-

There's an early 260Z and a late 260Z. There's also an early 280Z and a late 280Z. I'd start a new thread of your own, with the details of what you have and what you want to do. You haven't even posted the year of your 280Z yet. You're getting spread out over multiple threads and you're going to get lost in the answers. People who reply to one won't reply to the other, And if you ignore them in one they're not going to repost the same answer elsewhere. Just a suggestion. This thread is over 7 years old and BRAAP has moved on to other things, so most likely won't reply. Although, his profile says he was active 2 days ago.

-

Here's a good thread from the Frequently Asked Questions (FAQ) forum - http://forums.hybridz.org/topic/57506-240z-260z-or-280z-chassisbody-differences/ You need to be more specific than "mecanics". All of the moving parts are mechanical. Doors, wheels, engine, transmission, etc. The complete drivetrain, from engine to differential, from the 260Z 2+2 will transplant in to the 280Z, if that's what you're asking. Not many body parts though, if it's an early 260Z, plus the fact that 2+2 body parts can be different from coupe parts.

-

Watch the tachometer needle. It will tell you if you're losing spark. If you're in gear coasting, powerless, and the needle shows spark from the engine spinning, it's probably a fuel problem.

-

75-77 uses the fuel pump relay switch in the AFM. Some 78 AFMs also come with the switch, just not used. Post some test numbers and a description of what's "bad" and somebody might be able to help you out. You'll need a meter and knowledge of how to use it for Megasquirt anyway. Get some practice.

-

1978 280Z Heater Core Bypass Help

NewZed replied to oki_all_day's topic in Trouble Shooting / General Engine

A clue for you - http://forums.hybridz.org/forum/32-nissan-l6-forum/ What is Zeroyon? -

1978 280Z Heater Core Bypass Help

NewZed replied to oki_all_day's topic in Trouble Shooting / General Engine

Because this thread will be just one more of all of those you've read. Same people saying the same things. You need to reason it out and the answer will make sense when you're done. -

1978 280Z Heater Core Bypass Help

NewZed replied to oki_all_day's topic in Trouble Shooting / General Engine

Can't you read those various threads and posts and tell who knows what they're talking about and who's just talking like Ace Ventura? Does nobody have the ability to draw a conclusion anymore? -

Sorry, I didn't get it. My mistake. Thought you meant 280ZXT flanges. Good luck. BUT. You could get some plain old factory 280ZX axles, for the CV cars, turbo or 2+2, and swap those in. Here's a write-up. http://zhome.com/rnt/FordPower/HalfShaft.html

-

Apparently there's a lot of mythology out there, for all engines really, not just the L6 about what adds power. TB, AFM, CR - all suspect. BRAAP summarized these and added some fact-based reality in a past post. Not much dissent from his opinions. Worth reading. http://forums.hybridz.org/topic/95316-braaps-l6-efi-induction-advice-and-tips/ And all of these threads have value - http://forums.hybridz.org/forum/90-l-series/

-

As I understand things, the 240Z and 280ZX use the same diameter and spline count. People swap in 280ZX axles for 240Z, by modifying the dust shield. The 280Z is different. So the 280ZXT adapter might work.

-

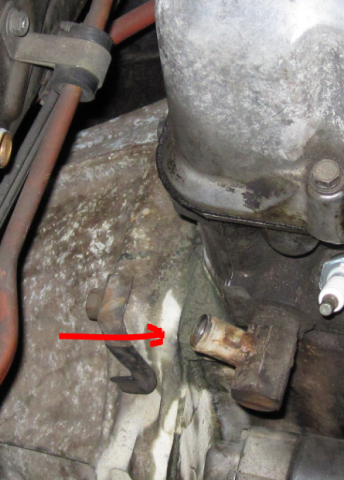

Here's where the coolant showed up on mine. Flat spot on the back corner of the block deck. No heater hoses in the way because I was removing the engine.

-

Stick your head down on the passenger side and look across the mating surface between head and block. You might get a better view.

-

It's not uncommon in the racing world. Why would you go with points if you can have electronic? Make a spreadsheet and put some cost estimates in for each item. The sum will be interesting.

- 18 replies

-

- n42

- flat top psiton

-

(and 4 more)

Tagged with:

-

Use an editing tool to mark up your photo. Can't really tell which dark spots are from a leak. The Snipping Tool in Windows Accessories is a good one. I had an HG leak on the passenger side, in the back. It would leak down over the starter and transmission while the engine heated up then seal itself once everything got hot. Stopleak helped for a while until it all extruded out of the gap. There's also a core plug in the back of the head that can leak. But external HG leaks aren't uncommon.

-

Here's a source - http://www.datsunstore.com/drivetrain-differentials-shafts-c-202_216_244.html?page=2&sort=2a

-

Those are 280ZX Turbo axles. Also used on the 2+2, I think. Put an ad in Parts Wanted for six hole 280ZXT CV axles. and you might find some used ones. Some parts stores might have them also but apparently the remans get their lengths all mixed up and people end up with axles that are two long. Be careful. Or there's the internet.

-

-

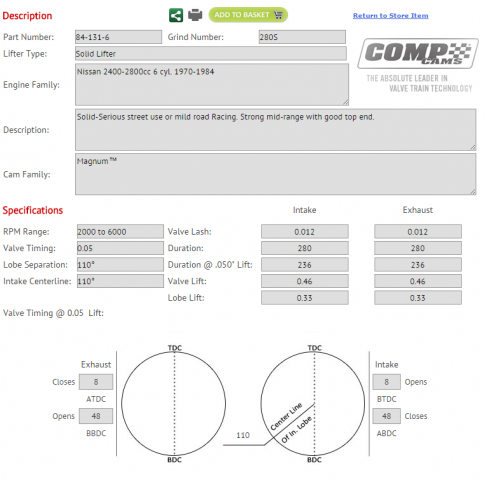

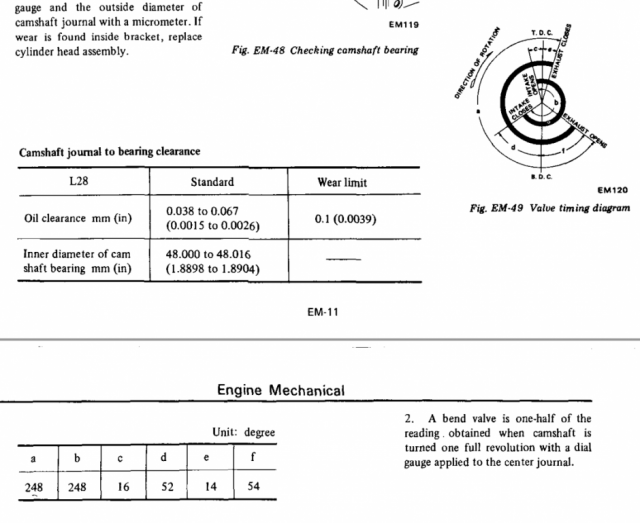

TDC is where the piston sites. The point of what you're doing is to get the camshaft in the right position to match the piston position. That's why there are adjustment holes in the camshaft sprocket. You should be thinking "all I need to do is rotate the camshaft slightly, with the piston at TDC, until the notch of the sprocket aligns with the groove on the retaining plate". That's why all of those marks are put there by Nissan. If you move everything slowly you could rotate the camshaft back and forth and until a valve touches a piston with no damage. Just for fun. There's room.

-

You said that the sprocket has already been on, just with the dowel in the wrong hole. Therefore there is enough slack available. Use the logic force Luke. Turn the camshaft.