NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

260Z's came with electronic ignition. Check the FSM. Shouldn't be any rust at all in the cap. Maybe on the distributor parts. Odds are though that you misplaced a wire. Doube check the wiring. Is "yo" really that hard to type in? Really?

-

Have you confirmed spark?

-

The engine gets hot,the engine bay gets hot. Air passes through the engine bay after removing heat from the radiator. "Air Conditioner" is a reference to the chapter in the Factory Service manuals. Drawings are there. http://www.nicoclub.com/FSM/280z/ The water cock is a valve that controls water flow through the heater core. Most likely location is between the hot water source and the heater core. Water hoses and control cables would be attached to it. Please don't ask where the hot water comes from. My car came with a bent control wire to the water cock. They get stuck, people push on the lever, the wire bends, the valve gets stuck open. Stick your head up under the passenger dash and see what moves when you push the heat control lever.

-

How about the heater core? Check your water cock, it might be stuck open. Operation is described in Air Conditioner.

-

How close are you? Post some numbers. Details on what's being tested also. I live in Oregon and they only test idle. How many retests do you get? I can roll through the DEQ line every hour for free if I want, until I get things right and pass. A lean miss will put you over, as will a too-rich mixture. Most old 280Z's run lean, and can benefit from a little extra resistance on the coolant temperature circuit. You said it doesn't have a catalytic converter. Is it supposed to? Usually that's an immediate visual fail. Your post is generally vague. Add details.

-

There's no functional reason to use that intake. Somebody has traded real performance for perceived performance. It will run worse but look faster. You didn't get my point on the turbo injectors. Your stock ECU is programmed for the flow rate of NA injectors. The higher flow rate of the turbo injectors will add too much fuel and you'll be enveloped in raw gas fumes, if the engine even stays running.

- 6 replies

-

- dewebbed intake

- l28et injectors

- (and 2 more)

-

The 240SX throttle body will be a bigger hole feeding the same 6 small holes. For the same change in throttle blade angle you'll get a larger change in aperture, giving the feel of more power but it won't be real.

- 6 replies

-

- dewebbed intake

- l28et injectors

- (and 2 more)

-

Setting timing for bolt on turbo to N/A engine.

NewZed replied to grillhands's topic in Nissan L6 Forum

Relative to what you need to know to get your engine running right, yes, the question above is "dumb". You need to learn the basics of how a typical engine works. Your lucky yours hasn't self-destructed yet, if it's not already damaged. You mentioned stuff that's bolted on but haven't even said what your timing is set to, initial, plus vacuum and centrifugal advance totals. You'll need to understand it anyway if you get the MSD unit. Many of us have damaged many parts, from your current knowledge level. Better to read a lot more and get a cheaper education. It might seem backward but the more primitive your engine management system is the more you need to know to get it to work right. The only "improvement" to your stock system is the FMU and all it does is add more fuel than stock based on manifold pressure (aka "vacuum), depending on how it's set up. You're in the Stone Age. -

- 6 replies

-

- dewebbed intake

- l28et injectors

- (and 2 more)

-

Cheapest Haltech is $854 - http://store.haltech.com/usastore/haltech-universal-ecu-kits/sprint.html DIYAutotune is a real company and Matt Cramer seems to do much more than many. Haven't seen any Haltech reps on the forum.

-

Big picture-wise, I wouldn't be surprised if Nissan used the K in the Maxima and the ZX. M stands for Maxima, a fairly plain passenger car with a 2.4 liter L motor. 1980's era, when gas mileage and emissions were king. Overall, you have an L28E, that will push that Z car about the same as all of the other stock engine options. You just need to decide if you want something to drive while you're researching, and building, that real performance engine.

-

Sounds reasonable. I'm not sure you can start a group buy with out a price and a description of what's delivered. It's in the forum rules somewhere. You can start a poll or survey though, of who might be interested, what they want, and what they might pay.

-

The K stamp has been reported before. Apparently it's a stock Nissan cam grind that just didn't make the internet lists. It's looking like you have a stock later ZX motor. Were I you I would at least bolt up the transmission and starter and spin it while you have the parts out. How far you tear it down to check it depends on how confident you feel about it, and your skills in taking things apart and putting them back together. Worst case, you install it and find out it's damaged. Or you tear it down while it's out and find out it's undamaged. It's a decision. Good luck. Your N42 exhaust manifold should work with the P79 head. The exhaust liners shoot inside the dimensions of the manifold.

-

Look at the very back of the cam for a letter or some stamped numbers. It looks like a stock cam, by the size of the base circle, although I've only seen a few. It might just be a stock motor with some "performance" rebuild parts. The headers might be considered performance parts. Or the guy just spun (span?, spinned?) a story about a stock motor. Regardless, if it runs well it might be a fair deal, considering the difficulty of getting motors in your area. Not a big difference between the two heads unless you port them, From what I've read. Hardly worth a swap. If the P79/F54 engine looks in good shape, put it in and drive. You can always swap heads later.

-

Didn't mean to divert your thread. But you have zero posts and your writing style is kind of like the style on the MFactory web site. If you want to get a group buy going, it would probably help you to show how this is different from the OBX, since it looks very similar. $300-400 less than Quaife is still more expensive than OBX, I believe (don't have the numbers). Share your correspondence with MFactory for a start. Always good to have options and if they can get in the game with a bolt-in product, rather than one that requires buying another party's modification package (the improved washers for the OBX), they would have an advantage.

-

Eibach Springs - Front sits high... *pics*

NewZed replied to PCressey's topic in Brakes, Wheels, Suspension and Chassis

If they're the same length the higher rate goes on the back. One quick way to figure things out. Put a heavy object on each spring, the one that gets shortest goes up front. Notice also that the difference is only 1/2", in your picture. That's F versus E on the gas gauge. Averages out to level rocker panels, which may be the way they were designed.- 48 replies

-

- suspension

- springs

-

(and 1 more)

Tagged with:

-

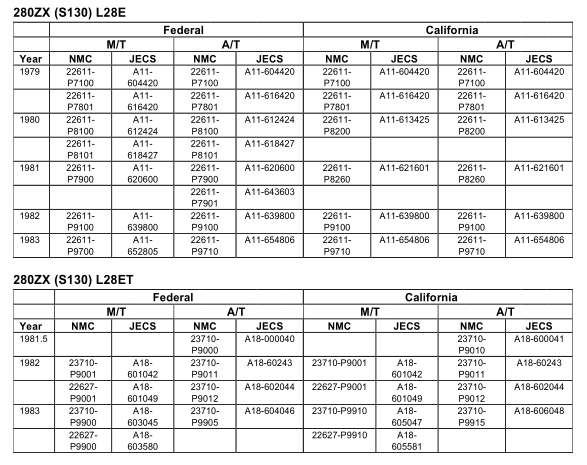

A Nissan Service Bulletin that I have says that's a ZX NA ECU. Lots of options on control systems, but most would say the stock ZXT system is hardly worth putting back together, from scratch. In other words, if you're going to figure out a bunch of wiring you might as well figure out something newer. Something to consider since it looks like you don't even have a turbo ECU.

-

Off-topic, I just thought the advice/info below from their web site was funny. "Gee wiz, one of my wheels is spinning. Good thing I know enough to tap my brake pedal." A common misconception is that a Torsen-Style Differential is useless under a no-load situation (e.g One wheel in the air). Thismyth has been further perpetuated by our competitors of whom have limited understanding of how a Torsen-Style LSD functions. This no-load situation does not apply to 90% of users. For the other 10%, there is a simple solution to the problem that our competitors will not tell you; simply tap your brake pedal. Isn't the design the same as the OBX?

-

Questions on parts to increase HP on N42 Block and Head

NewZed replied to HybridHydra's topic in Nissan L6 Forum

The clutch won't add any power. You'll need a different/modified crankshaft to get to 3.0 liters or more. Browse here - http://www.rebelloracing.com/enginebuild.htm After adding parts, the 90,000 current miles will be irrelevant. What happened to the RB26 swap? -

Looks like an 80-83 280ZX motor. The valve cover might be powder-coated but the block looks like factory paint.

-

Both alternators should put out 60 amps max. The ZX swap and rewire, in theory, won't change anything. A new 1975 style alternator might get you there for less trouble.

-

260zeto thought this was a bench-racing forum. Reality is hard to comprehend and a little bit of a shock for the bench-racer.

-

After ten years of sitting, the oil has drained from various surfaces that need it and there may be some condensed water in the fuel tank and crankcase. Odds are that the fuel pump has corrosion and won't work, there's rust in the tank to crap out the replacement, there may be surface rust on the camshaft and cylinder walls (some of the valves are open so at least two or three cylinders have been exposed to outside air via the intake or exhaust), and all of the electrical connections are probably corroded, at least a little bit. So if you want to be somewhat thorough you would pop the valve cover and lube up the camshaft, squirt some oil in each cylinder via the spark plug holes, drain the old gas from the tank and look for rust and water, drain the oil from the engine and look for water, and pull and clean the various electrical connectors, like on the fuel injectors, and the coolant temperature sensor, and the fusible links. The ECU and its connector can get wet also if the cabin area leaks. It's in the drip zone. Let the oil sit and spread for a while, then spin the engine with no plugs to get it distributed. Then put new fuel in and run the fuel pump for a while to flush out the fuel rail and injectors. Then put it all together and see if it starts. That's what I would do, assuming no major rust or damage is found. If you're lucky it's been sitting in a dry spot, all sealed up, in ran-when-parked condition, if you're unlucky,somebody left the filler cap and gas cap off and there's water and rust everywhere. If you want to be really safe, T another oil pressure gauge in at the sender location to be sure you have oil pressure. If it starts let it run and see what happens.

-

This statement alone makes the thread shed-worthy.

-

Good point. I didn't go that deep. On the second try, after confirming that a drill motor works, were you looking at a mechanical gauge or depending on the dash gauge? The stock sender and gauge are notoriously slow responding. Maybe you fixed the problem with the drill prime (the pumps do need priming) but went back to the bad measurement method.