NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

The video is just some clueless British guy selling match box car's from his bedroom. Looks like he still lives with his parents. The video gets worse and worse as it goes on.

-

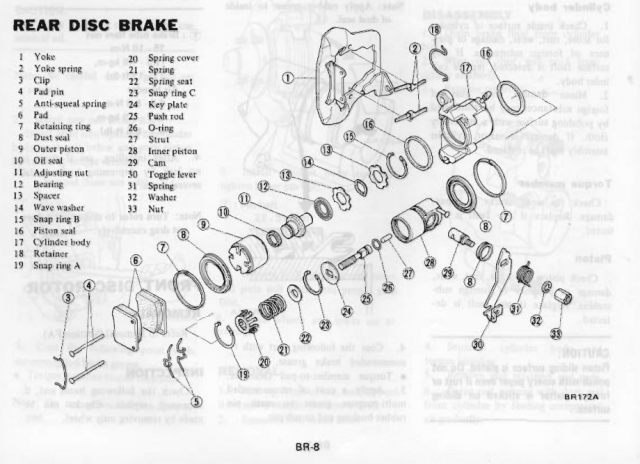

'82 280zx rear brake caliper rebuild question

NewZed replied to tamo3's topic in Brakes, Wheels, Suspension and Chassis

1979 and 80 look like they have the star-shaped spacers. But they use a snap ring, not the wire ring you show. -

L6 for L6 engine swap? What kind of "restore" are you shooting for?

-

Only one guy from "the community" has posted over the past week. ? It's kind of non sequiturial also, since rsicard only made a comment about the mainshaft. Doesn't follow.

-

has anyone installed Rx7 brakes?

NewZed replied to andyhorror's topic in Brakes, Wheels, Suspension and Chassis

I actually knew that, and realized the words were wrong after I wrote it. But left it anyway. Horsepower is measured with a big brake. Brake Horsepower. Edit - or torque is measured, horsepower calculated.... I got lazy. My point was really that the horsepower used to move the car is only relevant in that it's used to bring the mass of the vehicle up to a speed where brakes are necessary to stop it. But the horsepower of the engine in the car cannot be used to determine the horsepower required from the brakes. There is no need for a car's engine's horsepower to determine a brake system's horsepower. As you show above. "I have more horsepower, so I must need better brakes" is essentially a nonsense statement, unless you add the condition "because I will be going faster". The last part is usually assumed, but for a street car is probably not that relevant.- 59 replies

-

Or an enlarged combustion chamber. The head's been worked on. "Stage 3". Could also be the gauge. Using a metal adapter tube instead of the hose will drop a 180 down to about 120.

-

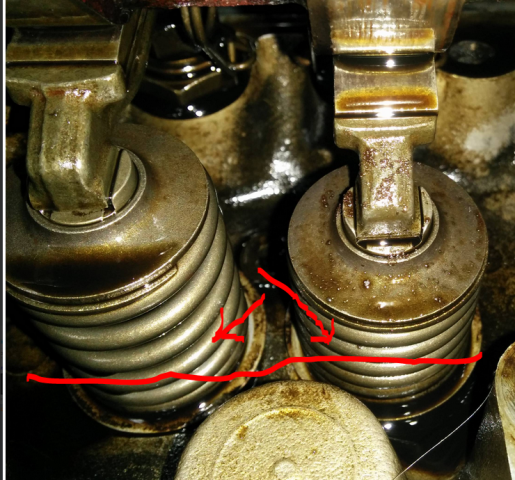

That's close. He wanted you to tilt the head so that the oil would be completely covering a valve seal. But it looks like your engine is still in the car so that might be difficult. Added a picture showing where the valve seals are (they sit around the valve stem and on top of the valve guide, where it passes through the head to the combustion chamber, inside the valve springs) and a squiggly line representing oil level for the test. There's a thread in the FAQ, L-Series section, about honing and re-ringing. Probably worth checking those valve seals first though. Since you have the engine apart and it's been sitting, take a good look at each valve to see if oil has been leaking by. http://forums.hybridz.org/topic/81528-replacing-piston-rings-with-the-engine-in-the-vehicle-l-series-faq/

-

s130 with z32 transmission driveshaft length

NewZed replied to redzedturbo's topic in Non Tech Board

There are dimensions in this thread that should be useful. http://forums.hybridz.org/topic/40192-transmission-dimensions/ -

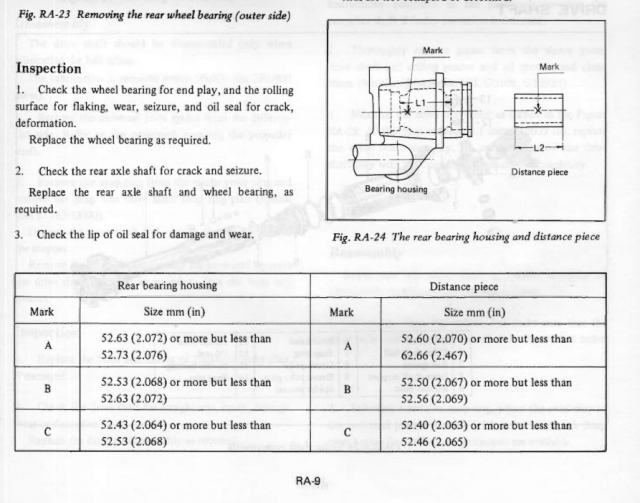

The pieces that sit on the axle are designed to match the inner race separation with the outer race separation of the bearings. The outer races are controlled by the hub. Not clear why you have shims in yours unless someone was making a worn or damaged "distance piece" work correctly. The Rear Axle chapter describes things, with some good drawings. You can make your own distance piece/spacer if you get the critical measurement from the hub and can create a good squared end on a piece of pipe.

-

Just connect the wires the right way. The point is that Megasquirt needs to tell the MSD box when to fire. All that you've done is show that the MSD box will do that if controlled properly. The fact that nothing is happening is an indication that MS is either not doing the controlling or that the MSD box and MS are not connected properly. Chill out and understand out what the Megamanual is trying to tell you. Then figure out how to make it happen. By the way, "square wave" just means off-on with a set voltage in the on state. Sounds more complicated than it is. And, actually, if you look up the definition of square wave you'll see that what's happening isn't really a classic square wave anyway since the off and on periods aren't of the same duration. It's really just a switching voltage from MS to the MSD box. Just some trivia... Anyway, in short, MSD isn't getting that switch from MS on the white wire, probably.

-

If it's not bad, switching to Redline MT90 gear oil, or a blend of Swepco 201 and ATF might get you by for a while. Here are a few links on the 71C swap - http://www.motortopia.com/cars/1973-datsun-240z-11118/car-pictures/240sx-transmission-swap-14041/DSC04293JPG_Thumbnail1.jpg-266482 http://home.comcast.net/~zheimsothtn/transmission.htm http://www.atlanticz.ca/zclub/techtips/240sxtransmissioninstall/index.html

-

It's been fine for years (how many and how many miles since?), or you just noticed it now? Or you just started engine braking on the hills? I don't think that cylinder pressure measurements will pick up worn oil rings, which would be the rings causing the problem. A leakdown test won't show it either. Stage 3 might just be somebody's cam grind label. Did you buy the head used or new? If the seals are leaking, the backs of the valves will be pretty oily and grimy, I believe. The seals on my old high mileage head let oil past them on to the valves just sitting on the bench after I removed it. I don't think that new ones will do that. Iffy lobes are not good.

-

Ask the guy that started this thread - http://forums.hybridz.org/topic/120458-cylinder-condition-advice-glazed/?do=findComment&comment=1127898 He's having problems, but it's been a year since he had the work done. May not be the mechanic's fault.

-

Transmission grinds in Reverse, after engine removal/installation?

NewZed replied to Mirage775's topic in Drivetrain

There is no reverse synchro unless you've swapped in a late model 71C transmission. You could have sucked in a little air when the slave rod extended, as it was removed from the transmission. Bleeding would be the thing to do. -

from "a square wave signal on its white wire" http://www.megamanual.com/ms2/msd6a.htm

-

You tested the MSD ignition module but you didn't test what triggers it. The MSD module is probably not getting what it needs from MS .

-

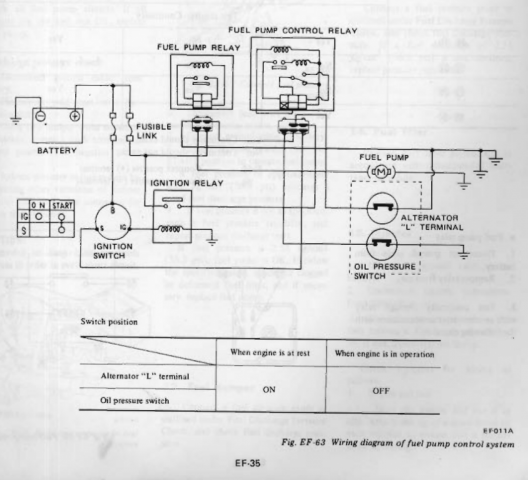

Most important - did the engine start and stay running? Put everything back together and just use starting fluid. You're kind of mixing variables, and jumping to hopeful conclusions. Your description is a little fuzzy also - the whole car clicks and hums? In the on and the off postilion? Can't understand. Could be that the click is a relay and the hum is the fuel pump. That would be normal. Also, you might have actually jumped the pressure sensor side of the switch connection. Pretty sure that the way to bypass the oil pressure switch is to just disconnect it. It's open when the engine is running, I believe. It's a flaw in the design. The diagram is hard to understand since Nissan says "On" instead of "closed", but I've seen others describe disconnecting the switch to make the pump run when the key is On. Just pull the connection and turn the key to On. I could be wrong. I have a 76.

-

That's a good one too, and very easy. I did have an ignition module go bad once though, that produced a spark only strong enough to start on starter fluid. Odd but true. Tools at hand usually determine which path people take.

-

1978 has a fuel pump relay that requires either voltage from the alternator or a closed circuit at the oil pump pressure switch, to keep the fuel pump powered. The relay is overrode during starting. That is one of many possible sources for your current symptom. Just an example. You need to start with the basics of fuel and spark and see which one is missing. There are many ways to do that, like listening to the fuel pump, attaching a voltmeter to the fuel pump leads, watching a spare plug for spark, watching the tachometer while it runs and dies (the tach counts sparks from the coil), attaching a fuel pressure gauge, supplying supplemental power to the fuel pump, etc. Pick a few and break the problem down until you're looking at the part that needs fixing. The Factory Service Manual chapters, Engine Fuel, and Engine Electrical, have many procedures and diagrams that will help. http://www.nicoclub.com/FSM/280z/

-

Why does my WUE only at 100% all over after Autotune?

NewZed replied to Meguiars's topic in MegaSquirt

You have several different questions all together, and some of them are pretty esoteric. Looks like a big mess to get involved. - Warm up enrichment (WUE) at 100% after autotune. - Lost sync. - Injector dead time. Apparently the table of voltages can be used to calculate dead time? You're asking someone to do the calculation or asking for the formula? - ASE taper time. What's that? From what I've seen, many people don't even use Autotune. It changes things that you might not really want changed. Most start with a basic known tune, then use the datalogs to make manual changes. Autotune is for the end when you're almost done tuning. You'd probably do better by listing the specs. of your engine and components, and the specs. of your Megasquirt system, then using one of the tunes that people have provided on the forum, to get started. Just offering an outside opinion. I don't have MS so can't even look at the three files you attached. If you have Windows you can use the Snipping Tool in Accessories to capture a screen shot. Might be easier than creating zip files. -

Checking float levels would be a lot easier. You might be focusing on what you're comfortable with instead of what needs to be done.

-

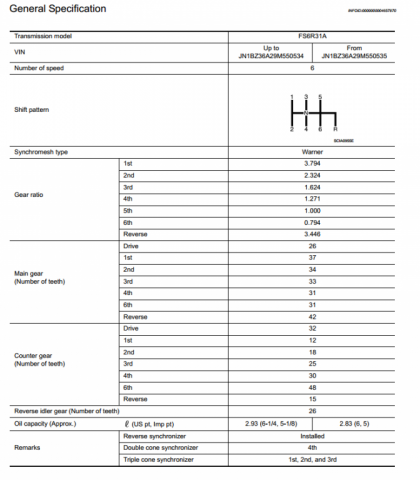

Interesting transmissions. 5th gear is direct, super low 1st, and the later models comes with triple cone synchronizers in 1st, 2nd and 3rd. Must be super smooth. Looks like they used about a 3.54 diff drive also.

-

Pretty sure that your stock 76 distributor will work. Locking the distributor advance mechanisms would allow MS to fully control timing based on intake manifold pressure and RPM. The VR wheel in the distributor is no different than a VR or HAll effect trigger on the crank, aside from higher accuracy at high RPM. You're getting closer to the point where you won't need to follow someone else's instructions. The DIY site has many incomplete writeups and broken links. For example, the one below. They're grown too fast. You just need to sift through the information and figure out what the fundamentals are for each of the various writeups and just figure out how to supply the board and software with what they need to work right. Many people try to do more than they need to do from the start. Like COP with a crank trigger. Not needed for ignition control, but it's pretty cool if you can get it done. https://www.diyautotune.com/tech_articles/megasquirt_ignition_control.htm#fuelsparkdizzy (Missing links and text that says "this page will be continued" but it never has).

-

This guy has a ton of parts, not all listed. Easy phone call. http://www.datsunstore.com/

-

EE-29 and -45 show some possibilities.