NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Oops. Subtract all injector references. Still, timing problem seems unlikely, assuming that the damper pulley mark is correct. By the way, the stock distributors are usually done advancing at 2500 - 2700 RPM

- 8 replies

-

- advance

- mechanical

-

(and 3 more)

Tagged with:

-

Nice story, good that you completed the mission. You don't have any numbers to work with though, on the HP estimate. "Crazy" 0 - 60 times, and, as noted, 135 mph with the wrong speedo gear. Plus, the 86 Mustangs came with an assortment of engines. Interesting that you went from EFI to Mikunis, are you just a carb guy or was that recommended. I know the stock EFI system is not really tunable for the modifications you made so that was probably the best way to get it done.

- 3 replies

-

- 280zx

- Build so far

-

(and 7 more)

Tagged with:

-

If ignition timing is off then all cylinders will be equally bad. Your timing numbers are in the right range for a smooth running engine, maybe not tuned for best performance, but still should run smoothly. Ignition timing is probably not the source of the problem. Injector imbalance is a possibility. Pop each injector plug off while it's running, one at time and see how the engine responds. You might find one or two that have no effect. That would be a clue.

- 8 replies

-

- advance

- mechanical

-

(and 3 more)

Tagged with:

-

Actually, you want to match the form of the exhaust manifold that you have. There are 280Z and 280ZX designs. The exhaust manifolds used on the stock P79 head engines (280ZX) are shorter than the 280Z manifolds (N42 and N47). If you get the wrong manifold it might fit the engine but you'll have to modify the transition to the exhaust piping. There should be a letter/number code on the manifold itself. Edit - actually you did ask for a ZX manifold so maybe you're already on it. Good luck.

-

Nistune daughter boards on ebay from Poland

NewZed replied to optimusprime8's topic in Nissan RB Forum

Post the link. Who wants to spend time searching for a cheap Polish Nistune board on eBay? -

"Rebuild" implies that you tore things down pretty far. Have you confirmed cam timing, reset valve lash, checked the cam for damaged lobes? It's not uncommon to damage a new cam.

- 8 replies

-

- advance

- mechanical

-

(and 3 more)

Tagged with:

-

When you do the typical conversion wiring, there are two hot wires left over. One is hot all the time, connected to battery positive, the other is hot when the key is On (maybe Accessory too). If you're just focused on connecting the wires that make the charging system work, you might leave those dangling. Two possible short circuits waiting to happen. I never figured out if they're fused or not, I just insulated the ends. Something to look at.

-

I saw those lips after I posted. Many people use a rubber snubber with the Techno Version mount, Maybe it's a little too wide for use with the GM mount. If you got the rubber diff mount with the R200, you could attach it and check its position over the crossmember to verify the diff's in the right spot. But your mustache bar looks correct and it's not going to move much. Check the fit of the GM mount holes over the diff holes side-to-side before you put things back together. I seem to remember needing to enlarge the GM mount holes to the inside. A round file worked. Look at Post #5 here if you want to compare TV dimensions to the original RT design. Notice the mounting area is different on the later cars also, at least one less lip, and maybe wider. http://forums.hybridz.org/topic/58895-what-is-the-deal-with-solid-diff-mounts/

-

There's three holes on each side of the TV RT mount, to mount it to the car body. Did you pick the wrong two? I don't know if it's possible, but there is another hole there. Looks like everything else is right.

-

You might find some diagrams in this sub-forum, or the answer directly - http://forums.hybridz.org/forum/90-l-series/ The turbo ECCS system is hard to work on. Nissan built an analyzer for it and therefore didn't put much in to the later Service Manuals. The 1981 Turbo Supplement has a good wiring diagram. Try that one. http://www.xenons130.com/reference.html If you're on a phone and can't open big documents, you'll just have to ask better questions or hope someone feels generous. Good luck.

-

It's still in the link I provided. Do some work. Check the coil bracket for a silver cylinder. Then open the EFEC chapter to figure out what it is.

-

The ignition module is not on the ECU, it's by the fusebox. Above and forward. http://www.nicoclub.com/FSM/280z/

-

Maybe it's the other end of the circuit, not the sensor end. A bad component that fails at high frequency. Have you tried the JimStim? Apparently, it replicates a clean signal from a variety of wheels. Looks like it was thought up and designed for exactly your problem. Not too spendy, especially considering the time, money, and effort you've already spent. http://jbperf.com/JimStim/

-

Good find. I assumed too much. Interesting thread. I learned something.

-

Sand. Lots of sand in my brand new radiator.

NewZed replied to Connor280ZX's topic in Nissan L6 Forum

Large water filter? There's probably room for one down by the bottom hose. You'd have to do some research on rates and particle size. Of course, remove and rinse is the obvious first attempt. I think that fill and shake might be more effective than turn upside down and flush. You need to get the sand to one of the openings. Then it's up to your comfort level wondering if you got all of it out. Most of the sand will probably settle to the bottom of the radiator anyway. -

-

PM'ed instead.

-

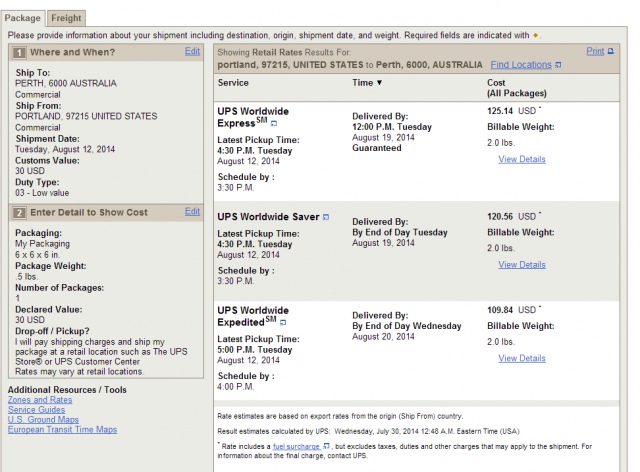

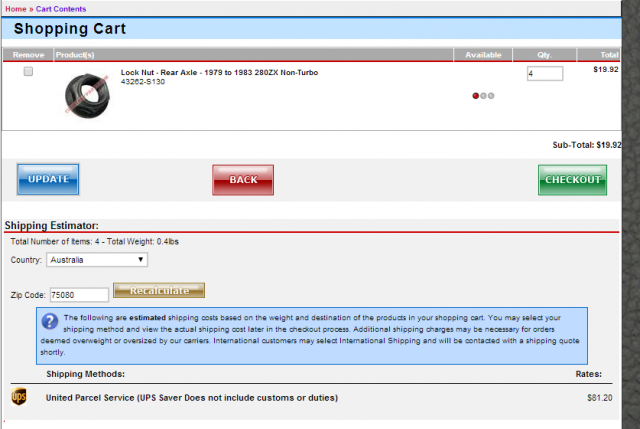

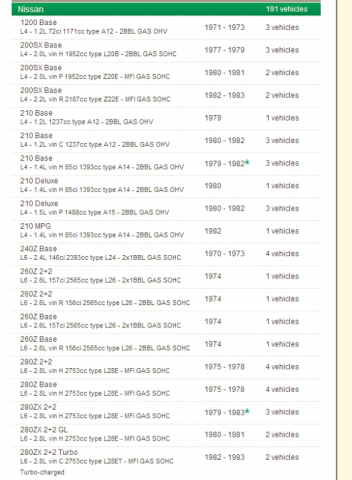

Courtesy sounded like a great idea. But, it looks like shipping gets you no matter where they come from. PM Tony D, he probably carries some around with him. I think it's not recommended but maybe you can re-use those nuts. Maybe. Used nuts might work, with threadlocker. I'd do it.

-

Coolant Overflow Tank Question

NewZed replied to Midnight-280Z's topic in S30 Series - 240z, 260z, 280z

Click on the Compatibility tab on the attached link and you'll find a few options. I copied some of the Nissan models in a picture. Could be that the upper rubber seal on yours just rotted away. They do that. http://www.oreillyauto.com/site/c/detail/MCS0/7013/03357.oap?year=1976&make=Nissan&model=280Z&vi=1209226&ck=Search_C2021_1209226_-1&pt=C2021&ppt=C0331 -

Coolant Overflow Tank Question

NewZed replied to Midnight-280Z's topic in S30 Series - 240z, 260z, 280z

The reservoir tanks were used before 1977. The caps all divert overflow to a hose. The only new question is whether or not the cap and radiator cap flange can hold a vacuum to pull the coolant back in. There is no extra valve just two round rubber seals. The main pressure relief spring and seal could be termed a valve. But it's the only one. -

Looks promising but I'll bet a lot of people get stuck here - Your Responsibilities are to make sure that the vehicle is not currently titled in your state, stolen, or salvaged. After five (5) years most titles are out of the system, but if you think your car is still in your state's computer, just contact your local "Department of Motor Vehicles" (DMV) and give them the Vehicle Identification Number from your vehicle. Then ask the status of the Title if any.

-

Most states require the registered owner to either release interest or apply for the new title, through a "lost or damaged title" process. Until the registered owner releases interest, the vehicle is theirs. You don't even need a bill of sale in most states, just the title in-hand with the release of interest signature. It doesn't matter who took money for it, or who possesses it if the title interest isn't released. That's my understanding. I've looked at a car or two with no title and you either had to go to the DMV with the registered owner, or find the registered owner and convince them to go to the DMV or find the title, This is in Oregon, other states may be different. I haven't seen a simple process described to take ownership with no title. I think that there may be ways to claim that a vehicle is abandoned and take ownership that way.

-

You might start a new thread with a title like "Which tailshaft housings will swap?" or something similar. So you can find the right one. There are a few guys on here who've had many of these transmissions apart and might know. I have an old ZX tail housing myself but am not really in to selling/shipping/internet stuff, beyond Amazon and eBay. But anyone who did the 71C/240SX transmission bellhousing swap should have 1/2 a transmission left over. They're out there.

-

Post a link.

-

Keep the v8 or swap to 2JZ?

NewZed replied to BluSkyLightning's topic in S30 Series - 240z, 260z, 280z

May or may not matter, but most 1976 cars have a voltmeter, you have an ammeter. Maybe it's an early 76, or it's actually a 75. Avoid some wiring confusion in the future. It looks like the Jeep market is really driving your engine options. They all look pretty tall though. http://www.tuffdawgengines.com/AMC.htm