NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

You can look at examples using Google images. It's not right.

-

Where are you and how much are you offering?

-

Why would the pistons from a "master rebuild kit" not work with the head and cam? Something is weird and probably wrong. You need to list part numbers or links. Master rebuild kit is too general. If it is just a stock rebuild but with 0.040" pistons, and you get it put together right, I don't think that you've listed anything that will add power over the stock engine. From what I understand, the stock manifolds flow pretty well, so the headers won't add anything, and flow to and from the cylinders is restricted by the head, so no gains with the manifold and carb. These engines aren't like old small bccok chevys with small carburetors and restrictive exhaust manifolds. It actually sounds like you're about to put together an engine that won't run on pump gas with timing optimized for power. It will probably be down on power when you get it running, because of retarded timing. Better do some more research, take some measurements, and re-calculate.

- 16 replies

-

- 240z

- horsepower

-

(and 2 more)

Tagged with:

-

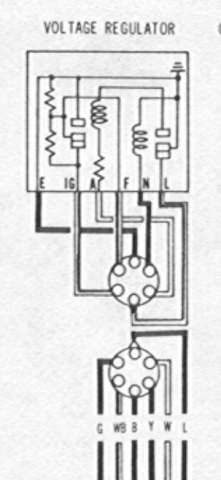

You'll lose the safety features and the voltage/pump speed control. Noisier than necessary, more load on the electrical system at idle. But the Z31 ECCS can't control the pump without its associated relays, so if you don't have those you shouldn't be trying to use ECCS control anyway. The picture's from 1986. 1984 is similar. Around page 27-29 in the EFEC chapters.

-

Just curious as to how these things happen. I think that the stock 280Z tach counts six coil discharges as one revolution. So you'll have the signal problem to solve and the math problem of making four look like six. These adapters look interesting - http://www.summitracing.com/search/part-type/tachometer-adapters http://www.dakotadigital.com/index.cfm/page/ptype=product/product_id=127/prd127.htm http://www.dakotadigital.com/pdf/SGI-8B.PDF

-

It's interesting to think about. I wouldn't call it a non-starter. With a lubricated bushing at the contact point of the mount and the control arm tube, the arm could probably pivot fine, But, with the stock rubber bushings deflecting side-to-side, the diff alignment would be off as you cornered. Using urethane bushings to stiffen things up, a lubricated metal bushing at the attachment points, and you're left with "can the tubes handle the load without bending?". Just a thought experiment, building on the AZC design. Application would matter. Drag-racing not a good idea, street car maybe fine. Apparently rags is using the AZC version, modified, post #17 - http://forums.hybridz.org/topic/119147-arizona-zcar-rear-suspension-design-function-flaw/

-

The voltmeter should always indicate system voltage, even with the key off. Most likely cause of your problem is dirty battery connections.

-

You don't need any of the wires from the factory harness to get the alternator to charge. You can run separate L and S wires, ground through the body or run an extra wire, and run a main charging wire to the battery or the starter lug. You should figure out how the alternator works first, you'll need to know that anyway even with another harness. Unless you're planning to go back the the external regulator. There is no easy path when working with the electrical system. Put the seeds down, open up the wiring diagram file, and get your meter out.

-

So the short nose diff mount system (actually two mounts), the front one, is an AZC product? I've looked all over the AZC site and didn't find it. I started another thread about it, since I've never seen it and there doesn't seem to be a simple mounting system out there. Seems like the concept could be applied to the stock control arms, maybe with a bushing that allows rotation and a bar connecting the two, like you describe.

-

83 280zx...what should I take off of it?

NewZed replied to Spirit7's topic in S30 Series - 240z, 260z, 280z

Differential. Wheels. Half-shafts. Front struts. -

Thanks for that. I looked through the AZC site for instructions or descriptions but didn't find that page. Funny that the page is called the "lowarms" page, but the picture doesn't show them lowered. Running them lowered would put a lot more turning torque on the inner tubes. And still not clear why you'd have plastic sleeves if you're "locking tightly". The two things don't go together. The overall path to this point seems cloudy. Still curious if anyone's seen any signs of movement. But if people are happy with the design, there's no need to change it.

-

Silvermine Motors is using the same design. Looks like they are aware of the roll center change possibility (better geometry, below), but are just using the clamping force of the stock brackets to keep the bars from spinning. Also looks like they could easily have put the heim ends on the same center line as the original arms. Interesting how these things come about, I wonder if the original goal was the geometry control or if it was recognized after the fact. http://www.silverminemotors.com/datsun/datsun-260z/suspension/rear-lower-control-arm-cnc-for-240z-260z-280z "These arms allow for full adjustment of the suspension geometry without having to remove any parts! They allow for on car adjustment of camber, and also the length is adjustable and the pick-up points can be raised for better geometry. Constructed of high grade T6061 aluminum. They can be anodized different colors per customer’s request. These control arms are extremely strong compared to factory parts, and they look BEAUTIFUL! Work great for extreme driving conditions. Please allow 2-3 weeks for delivery."

-

Actually, if you look at various pictures around the internet you'll see that big tube pivots also. Plus, AZC has what looks like Delrin bushings at the ends of the big tube. I thought the same thing and wondered about the effect of creating a shorter transverse link. But after looking around, decided that it's meant to pivot. Maybe it's not. If so, I don't know what the plastic end pieces are for. I started another thread about the AZC arms and how they work - http://forums.hybridz.org/topic/119147-arizona-zcar-rear-suspension-design-function-flaw/?do=findComment&comment=1116443 But, if one wanted to, they could lock the big tube down, use the heim joints as the sole pivot, and the big tube could be welded or bolted to. You'd have the shorter control arm though, if that matters.

-

I didn't consider the half-shaft. Good point. As far as loads though, the outside wheel will be exerting a load directly across those three pivot points. The half-shafts and diff may well be taking up the load when buckling occurs. I wonder if people with the AZC system have extra diff or half-shaft problems. I've got locked in to wrong understanding before. But I think that the design here lends itself to buckling. Under normal driving conditions, the shift off center is probably small. But in a hard corner, with body roll, I think that it has to being trying to buckle. Once it's off center, there's nothing to stop it. Except maybe the half-shaft at full compression. As noted in another thread, maybe the big tubes don't spin. The assembly pieces, plastic (end bushings) and various pictures on the web (varying angles of the attachment points) seem to indicate that they do. Maybe I just don't get it. Why wouldn't you just attach the heim joints so they have the same pivot center as the original arms?

-

I've seen a variety of different error messages, and been able to get halfway on to the site, certain pages show but no links work. No problems now, using Windows 7 and Chrome. I've heard bad things about IE.

-

Seems like it could be a nice simple easy to make option. Who knows. On the Kindig It people - I see a reality car show in the future: http://www.kindigit.com/about-us.php

-

Found an interesting short nose diff mount on a car for sale on eBay. Someone on classiczcar started a thread about the car. Notice the custom mount for the nose, using the AZC control arm tube as the mounting point. Since the tube spins, the mount can't control fore and aft movement but it does support up and down. Stole a picture, the link is attached too. It could probably be made stronger by connecting both sides of the two mounts, making it one crossmember that hangs from the control arm "system" tubes. Forgot to say, this concept should work for the stock control arms also. I don't know if those are AZC parts or the car designers. The designer is Kindig It Design. Never heard of them until now - http://www.kindigit.com/ http://www.ebay.com/itm/Professionally-restored-1972-Datsun-240-Z-Resto-Mod-/161386307368?afsrc=1

-

I've never really seen a good picture of the Arizona ZCar rear suspension installed. It seems to me that with three pivot lines in the suspension that the control arm could buckle inward around the main big tube. With the weight of the car pressing the strut outward, and the lines of force mostly centered during cornering it apparently doesn't happen. But under the right (wrong) conditions I don't see how it could be avoided. This would allow the wheel to move inward quite bit. Am I missing something? Has anyone heard of problems with this system? I'm pretty sure that I made a similar comment about someone's home design in a past thread. Didn't realize that AZC was using it. Attached a picture that I borrowed from Whitehead Performance and a simple drawing to illustrate. http://www.whiteheadperformance.com/1971-datsun-240z-restomod-rear-suspension-build-wilwood-arizona-z-car/#prettyPhoto

-

One of the great benefits of owning a Z over other old sports cars is that there are wiring diagrams and service manuals all over the internet, free for opening, saving and/or downloading. You're going to need more than just knowing "constant power" wires. Use the Google with the right words. Search classiczcars.com and you might find the full-color versions.

-

Some multimeters will measure voltage frequency (Fluke 115, for example). Might be worth a shot on the sensor. If it shows up dirty at the same RPM range, you'll know it's the sensor or noise on the signal. If it doesn't anything, the meter might just have better noise filtering, or it may not be the sensor at all. Might not be conclusive but it might tell you something.. You'll have to know RPM at the same time or do some math on the meter number, since you'll be getting 35x RPM.

-

There are a couple or more good threads in the link below. People have made the turbo engines work in other cars with everything from the stock 280Z EFI system and a rising rate FPR, 300ZX ECU swaps, Pathfinder ECU swaps, up to aftermarket EMS, like Megasquirt. The Ultimate L28ET Guide... thread is probably the best for you. http://forums.hybridz.org/forum/90-l-series/ DIYAutotune is the place for Megasquirt - https://www.diyautotune.com/

-

The extra wires are from the external regulator plug. The big green IG wire for sure, and one of the others, I can't remember what all of the letters mean, if I ever knew them. Maybe the white wire. The only wire you really need from the harness is the L wire. The others can all be run directly from the alternator. Your car probably has the brake warning lamp check relay to cause you problems. It's connected to the yellow wire and will drain your battery if you use the atlanticz write-up, because the relay will be powered all the time. I had to rewire mine to the fuel pump power circuit. I still have my EFI and fusible links, all intact and working.

-

Part Identification - Fuel Rail/Throttle Linkage

NewZed replied to Dramier's topic in S30 Series - 240z, 260z, 280z

It's a vacuum actuated idle speed increaser, activated by the AC switch. There should be a vacuum hose connected to it, that runs to a solenoid over by a yellowish-white plastic bottle on the passenger side. -

Search around for VK56 swaps and see what cars they fit in. Here's a 350Z swap, with a little bit of a hood clearance problem. Here's a thread for a 240SX swap. It's in Stanceworks though, so the engine will be taller than the car when he's done. http://www.stanceworks.com/forums/showthread.php?s=57eb119f964788241869ccde76ca63c6&t=50721&page=2

-

Are they from Chequered Flag or MM.?