NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Turn the rod so that the threaded portion on the end of the rod gets shorter. In other words, the effective rod length increases. You can actually turn it without removing the clevis pin in the pedal, by loosening the locknut and using a pair of pliers on the rod. You'll be able to watch that gap between the rubber stop and the pedal close up. Looks like you have quite way to go because the pedal spring is pulling the rod out to the limit of the retaining clip in the master cylinder. You should be able to lengthen the rod until the pedal spring pulls the pedal against the rubber stop and there's a little bit of play/slop around the clevis pin. Hopefully you have a good pin, they get a groove worn in to them over time and can add some sloppiness. You have a lot more travel in your MC than you're using now.

-

The new hole is shown in the link I edited in above. Since it's on the rod, it's just 22 mm forward. Who knows, there's not much to it, you could probably get it right with a hand drill and a tap. If it was me and I had everything all put together and working, I might even drill and tap without taking it apart, but with the transmission out, on its side and working from underneath so the chips fall down and out. But I'm lazy and like an odd challenge. You can also see the notch on the 71C shift rod in his pictures. Looks like that would be your problem source sine you started with a 4 speed housing. A measurement of hole location comparing the two housings would also tell. There should be a 22 mm difference. http://home.comcast.net/~zheimsothtn/Transmission2.htm

-

I can't imagine someone drilling a new hole. Where would they put it? I think it sits in the notch in the shifting rod, and is actuated by the edge of the notch. You can see it in the sixth and seventh pictures of Post #10 in this link - http://www.classiczcars.com/forums/engine-drivetrain-s30/49070-transmission-id-quiz.html Lots of swaps done and no reports of reverse switch weirdness. Maybe get a mirror up in the hole and see if something's bent inside and can be nudged aside. Maybe your shift rod is 180 off, did you repair any shift fork damage? You should be able to see that notch. You might be right, there could be something wrong inside the transmission. Edit - Found that reference you talked about. Apparently the four speed front cases had the switch in a different spot. Meaning they must have used a different style shift rod. I used a ZX 5 speed housing so no problems for me. You could probably fix it just by swapping shift rods, I would guess, or machining a new notch in the rod. Might be easier than machining a new hole in the case. Still, a look through the hole will probably tell the story. Sorry to monopolize your thread, good luck. http://home.comcast.net/~zheimsothtn/Transmission2.htm " Here's one I haven't seen mentioned before; the reverse gear switch is located about 22mm further back on my F4W71B than on the FS5W71B or C. Since I didn't realize this until after I chose the 4 speed bell housing to modify (it was already out of the car), I had to drill and tap a new hole in the side of the case to make my reverse switch work. If you're using a 5 speed 71B bell housing, this is not a concern."

-

Not really understanding what's going on. You say waiting for them to kick on, implying that they were off, but then say that they stayed on, implying that they were already on. And the switch and wiring test out good. ?? Anyway, your car, your problems, Something to work on. You could always just wire in a console switch in the meantime, until you figure it out.

-

Seems like a lot of work for pretty certain. Have you logic'ed things out? You said the reverse lights are always on. Meaning the switch contacts are always closed. You might be able to back the switch out a few threads to get the contacts to open. Or you might just have a stuck switch, You can probably swap it with one of the extra ones, from under the car. Even if you took the transmission out and removed the front case, that's probably what you'd end up doing anyway. I have a 1985 71C transmission with a ZX bell/front case on it. It's sitting in the garage so I checked the switches. The reverse switch is the one directly in front of the fill plug on the right side. It works fine, reverse = beep, anything else = silence. There's also a neutral switch on the back half, right side. Good luck, don't get carried away.

-

77 280z odd timing, stuttering, hesitation on throttle

NewZed replied to ISPKI's topic in Trouble Shooting / General Engine

It's in between before adjustment and after adjustment, it can't get better. The distributor rotor orientation is fine. If the distributor housing is twisted too far, that means the ignition timing is off. Get a timing light and set timing. -

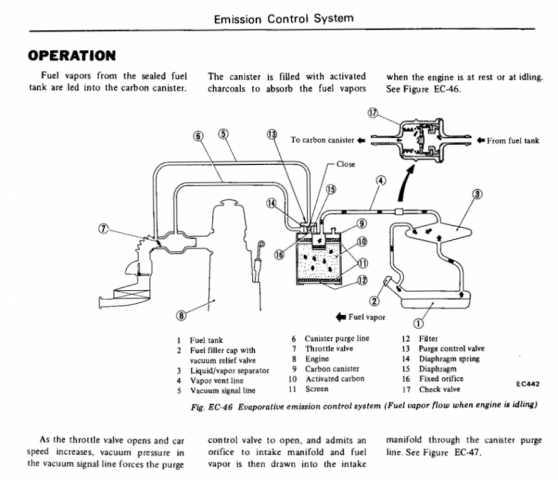

Why does this "sound right"? That pressure should be released through the charcoal canister. The big pressure release indicates that something is screwed up. My stock 1976 280Z with the complete venting system (lets pressure out), including the stock charcoal canister, and vented tank cap (lets air in), and aftermarket Airtex E8312 fuel pump is very quiet. A couple of pieces of rubber between the pump body and the mount, and I can only hear it in a quiet garage with the pump only running, engine off. Nobody should have to live with a noisy fuel pump.

-

The switch is located over the reverse gear mechanism of the transmission, probably the shift fork. It can't be moved anywhere. You may have plugged in to the wrong switch, like a neutral indicator switch. Use an ohmmeter or test light and find the switch that closes when the shifter is in reverse location. Or just try them all until one works right.

-

Engine Identification help (P79/N24) am I dyslexic?

NewZed replied to JakeWard's topic in Nissan L6 Forum

How about a W? W24. Here's one link that a Google popped up. http://www.zcar.com/forum/10-70-83-tech-discussion-forum/110832-w24-block-n47-head.html Are you looking in the right spot, above/around the left side motor mount? Might be looking at the wrong number. Edit - the spot looks about right by the picture - http://www.xenons30.com/Engine.html Looks like a Maxima block - http://forums.hybridz.org/topic/67452-w24/ -

You could run two legs from the cross-member up to the old diff strap mount holes. The diff strap mounting bolts would be in shear and would stop the motion. Basically a boxed mount off of the cross-member with the two tongues sticking out front to hold the diff nose. It would be stronger but still puts a bending load on the tongues. Adding two more legs diagonally from somewhere close to the front of the tongues back and up to the diff strap mount hole areas would help that problem, making the tongues shorter. If there's room. As an assembly it might be pretty big and bulky.

-

That diff mount design puts a twisting motion on the four mounting bolts of the cross-member. The nose of the diff is pulling up on a fairly long lever arm with the four bolts of the cross-member as the fulcrum. It wouldn't be surprising if the heads of the bolts broke off eventually.

-

Controlling ls2 coil with ground signal?

NewZed replied to nimeton's topic in Ignition and Electrical

AEM says yours won't do internal "igniter" coils, the system has its own dwell control. Anyway, the LS2 coil itself isn't extremely powerful, it's the coil and its control system combined that get things done. You could probably find a way to bypass/hack the LS2 coils' internal igniter, which might be fun, but there must be comparable "dumb" coils out there. There's an AEM forum out there that might have some ideas - http://www.aempower.com -

Controlling ls2 coil with ground signal?

NewZed replied to nimeton's topic in Ignition and Electrical

Does the AEM Series 1 do COP (near/at) or individual coil control. There's not much out on the internet about the AEM Series 1. Did you get instructions with it? Post a part number, the Series 1 probably wasn't named until they came out with Series 2. Most of the AEM internet stuff is about plug-n-play in to factory harnesses. -

More details? Year, bumper style, wheels... There are a lot of brown Z's out there. There must have been something special about the one you thought was yours.

-

The PRW-2 transistor might be a better option. Does the same thing as the original, and designed for it. Pasted a link below. Most of the improvements cited in the thread are probably the same as those you feel after you wash your car. The ECU controls timing and dwell, no reason for a different transistor to have any effect.. It's a start but you'll have to put some thought in to the wiring. The second link has wiring diagrams. http://z31performance.com/showthread.php?17796-Upgrade-to-PRW-2-Ign-Control-Module-(Power-Transistor-Unit) http://www.nicoclub.com/FSM/

-

Actually Stagg shows two different part numbers for the front of a 280Z. 552205 and 552206. Posting the three links that you probably looked at. The Brand page even shows the two gland nuts, so at least the pictures represent what they ship. Maybe someone at Stagg and/or Brand will see it and do some housekeeping. http://staggshocks.com/Stagg%20AG/Stagg%20AG%2075-78%20Nissan%20280Z.html http://www.brandcarparts.com/1975-1978-nissan-280z-stagg-front-shocks-and-struts-2.html http://www.brandcarparts.com/1975-1978-nissan-280z-stagg-rear-shocks-and-struts-2.html Edit - Stagg shows the same part numbers, with the same error, for the 240Z. They probably got their fronts and rears switched and put both 240Z and 280Z numbers on the page. Maybe 280Z rear is actually 552206, and 552205 (which you got) is the 240Z rear. Brand doesn't list part numbers, only application, so the order process is kind of screwed up. http://staggshocks.com/Stagg%20AG/Stagg%20AG%2070-73%20Nissan%20240Z.html Did your old gland nuts fit tightly on the top of the shock?

-

Need help with ID on Trident Engineering race motor

NewZed replied to Nate SERE's topic in S30 Series - 240z, 260z, 280z

Put "Trident Engineering" in your thread title. It will catch the eye of anyone who might know. "Help ID motor" does not attract the eye. The machine work on that valve cover probably cost some time. -

Thank you for the apostrophes. There is at least one thread in the last month on installing a GM V8 in to a 280ZX. Try searching V8 280Zx and see what happens. Use Google since the Hybridz search engine doesn't do two letter words. site:hybridz.org v8 280zx 2014 http://forums.hybridz.org/topic/118786-looking-for-v8-kit-for-a-83-280zx/ http://forums.hybridz.org/user/29243-daflyinghawaiin/ http://forums.hybridz.org/topic/118569-l98-tpi-vs-lt1-swap-in-280zx/

-

The materials and process being used are very modern and will give a very high-strength product when done. But for what the part is, it seems over-designed. Unless it's meant to add rigidity to the body. Not to put a damper on progress, just a statement. Once the mold is built, you could spray chopped fiber and polyester resin, or even pour urethane or urea foam around an inserted framework. Done right, it could even have a soft touch to it, like the original. If he wants to make some money, shooting for volume might be the way to go. Another perspective. Carpenters think about wood and nails, mechanics think about metal and bolts. If you work with pre-preg and have an autoclave, everything looks like a structural piece.

-

Droop limiters?

-

260Z L28et swap... good purchase?!?

NewZed replied to 20STi11's topic in S30 Series - 240z, 260z, 280z

Actually, there are more variations than just four. I only know what I've picked up from various magazines and the internet over the years. http://www.fuelairspark.com/fas/efi-systems -

260Z L28et swap... good purchase?!?

NewZed replied to 20STi11's topic in S30 Series - 240z, 260z, 280z

Were I you I would ask - Was the engine rebuilt professionally (by whom, if so), or was it rebuilt in the owner's garage? What exactly does "rebuilt" mean? Where are the receipts? Which of the four FAST EFI systems is being used? Where is the dyno sheet? Then take it for a drive and see how it runs. Many people think that new gaskets and rings is a rebuild. Or new pistons and rings. Or just new gaskets. Your biggest problem is that you've been driving a newer maintenance-free car, and don't seem comfortable with engine work. You should probably take someone that knows engines along. People blow up fresh engines with turbos sometimes, just trying to tune them. Parts-wise, a professionally rebuilt engine, with a new FAST EFI system that works.might be worth the money alone. But an old engine with new pistons (because detonation destroyed the old ones) and a poorly tuned EFI system maybe not so much. The messed-up wiring has to make you wonder about the engine work. It does look interesting though. -

Maxima alternator swap questions(search isn't helping)

NewZed replied to Milenko2121's topic in Ignition and Electrical

If you're comfortable with wiring and wiring diagrams the S and L wires can be figured out from the Electrical chapter. http://www.nicoclub.com/archives/use-nicoclub-coms-factory-service-manual-database.html Napaonline sometimes has a diagram for their parts. Like the Bosch reman, there's a PDF file about Bosch plug pinouts. Click on "Voltage Regulator Plugs: pdf file. Looks like H7 style, Hitachi. http://www.napaonline.com/Catalog/CatalogItemDetail.aspx/Alternator-Remfd-90-Amp/_/R-BSAAL338X_0416358641 Rockauto.com has pictures of the plug area. Piece everything together and it's figurable. -

Little beeping box. What is it?

NewZed replied to herhuskyZ's topic in S30 Series - 240z, 260z, 280z

-

Time for poly bushings...recommendations?

NewZed replied to wesmc's topic in Brakes, Wheels, Suspension and Chassis

Some say that you're fine with urethane on both sides if you also replace the inner control arm bushing. If it's worn the arm won't be in its correct location and stresses the end of the TC rod. You'll know you have a problem if you hear a lot of groaning as the front suspension works. Mine groaned until the end of a rod broke off. The groaning went away after I replaced the rear bushing with rubber. Eventually I replaced the inner control arm bushings but never put the urethane back on the backside of the TC rod. It really serves little purpose anyway since it sees little load except when the brakes are applied in reverse. The rod end breaks because the stiff urethane pushes on the tip if the rod, flexing it at the shoulder of the threaded area. That's where mine broke, after I nudged the curb in reverse lightly while parallel parking.. The end of the break had signs of flex fatigue, the curb finished it off.