NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

no power to fuel pump and butchered harness

NewZed replied to bahelion89's topic in S30 Series - 240z, 260z, 280z

Edit - I might have mis-read the "momentary power at startup". Maybe Pharaohbq meant when Starting. The "momentary" part got me since the power stays on if the engine starts and runs. As for having power with the key On but engine not running, that's not factory. There's probably some funky PO wiring you'll have to figure out. EF-15 describes well what the factory designed it to do. Good luck. -

no power to fuel pump and butchered harness

NewZed replied to bahelion89's topic in S30 Series - 240z, 260z, 280z

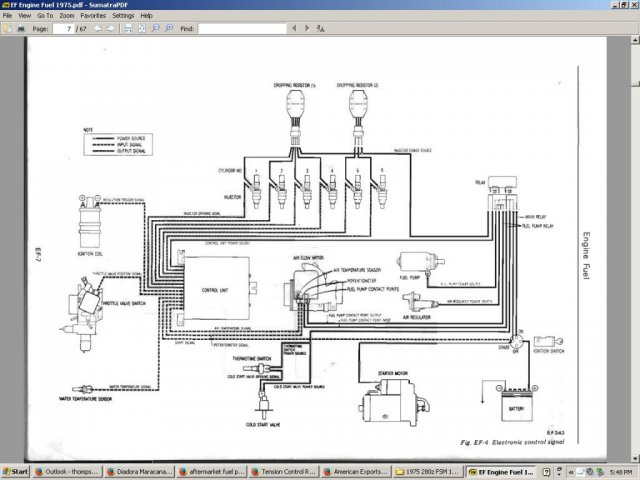

Read EF-15 (not 14) and look at EF-7. The pump never gets momentary power, that's a 280ZX feature, not 280Z. The wires in the tunnel could also be left over from the vacuum advance solenoid power switch that the original 4 speed had. Emissions chapter. Check them for power with the key On to be sure you don't have a short circuit waiting to develop. Note that there aren't many shortcuts or tricks to get the EFI working right. The emissions system from the PCV to the charcoal canister need to be connected and working properly, with no vacuum leaks, for the ECU to meter fuel correctly. All air must pass through the AFM. Even the dipstick needs to be sealed. -

The spot where the water runs down the block may not be where the leak is, depending on gravity and flow path. I had a water leak at the back of an N42 head, only from the coolant system outward, no internal leakage. A tube of Bar's Stop Leak fixed it for while, until the material eventually extruded out of the gap. If the gaps are small enough, it might work for you.

-

Maybe the problem is not the EGR sytem at all. Since you've had the intake manifold off, several other important hoses must have been removed. One that's not obvious but people forget sometimes, is the PCV hose connection underneath the manifold. I would check all other possible intake leak sources, including the injector seals and manifold gaskets. And since the engine runs, you can test for leaks using a flammable fluid like carburetor cleaner or gas like propane at the possible leak areas. Listen for a change in idle speed. Don't start a fire.

-

no power to fuel pump and butchered harness

NewZed replied to bahelion89's topic in S30 Series - 240z, 260z, 280z

if u. have read the fsm you would know that is not right. Unfortunately, learning about your car via the internet is going to be difficult because you are from the new phone-based generation. The diagrams and drawings are just very difficult to see and understand from the tiny phone screen, not to mention the difficulty in communicating via tiny word replacements like "u" for "you". Plus, the general weakening of thought processes that seems to occur from thinking in text-speak. Kidding, but serious. You could look at one page and read another in the FSM on a full-size screen, and understand exactly how the fuel pump circuit operates. The operation of the fuel pump is described and illustrated in the Engine Fuel chapter. Key words and acronyms are AFM, EFI relay, fuel pump relay, and fuel pump contact points. Good luck. -

no power to fuel pump and butchered harness

NewZed replied to bahelion89's topic in S30 Series - 240z, 260z, 280z

I'm going to guess 75-77 280Z with a 5 speed swap., based on the problems and pictures. Six posts and the writing style suggest that you may not know how the 75-77 fuel pumps get power, possibly believing that the pump should be powered when the key is on. That's not correct. Just guessing. How close am I? -

Is it possible to run the diesel L6 front cover on a gas L6 engine? Aside from the area behind the water pump, what else would be different? Maybe you have a diesel L6 cover.

-

I wonder if some marketing guys have been reading the forums.

-

I'm just a rookie but the only thing that would "use" the RPM data would be the ECU. The CAS delivers that information, the ECU uses it. Seems like a map, or look-up table, issue in the ECU program, if it happens exactly at 3500 RPM no matter what (note that the stock tachometers are not super accurate, so 3500 may not be 3500). The map, programmed for the stock Z31 that the ECU came from, is doing something at 3500 RPM that your L28ET engine doesn't like. Maybe the ECU is expecting other information at 3500 RPM and it's not there. The ECU might be switching modes, and getting poor information from the sensors after 3500 RPM. Or it might be switching modes because it's getting unacceptable information from the sensors. For example, one mode that switches at 3000 RPM is the injection mode, from group injection to simultaneous. Another one is EGR at 2700 RPM. Another one is RPM limiting to 2000 RPM if the MAF signal is bad, which doesn't seem to be your problem. These numbers are from the 87 FSM. Of course, since you're getting a CAS code, it might just be that the CAS signal is consistently breaking up exactly at at 3500 RPM every time. They might be the same problem or two different ones. Just offering a different perspective. Helps me learn. Good luck.

-

Raising fuel pressure should have fixed a lean problem and possibly created a rich problem, assuming the same injector open times. The ECCS assumes a certain fuel pressure so it seems like that should have had an effect. It was just a guess. As for timing, I didn't think through how the Z31 ECCS system works. It would probably be worth some study though.

-

Connect the two hose ends from the solenoid valve or run a new, longer, single hose. Make sure to insulate any wire ends that might have power if you remove the solenoid.

-

The wiring of the ECU connection is not the same, so even if you swapped AFM's, you'd still need to swap EFI harnesses too.

-

Some of the popular brake swaps end up with the bleed bolt at a position other than the very top, where the air is. The bleeder needs to be where the air is, otherwise fluid flows past but doesn't take the air with it. You might have to remove a caliper mounting bolt to rotate the bleeder to the top for bleeding then put it back for use. Just something to check, I'm not familiar with the details of your swap.

- 48 replies

-

- brake bleeding

- bleed

-

(and 2 more)

Tagged with:

-

Check bleed valve orientation.

- 48 replies

-

- brake bleeding

- bleed

-

(and 2 more)

Tagged with:

-

Noob Looking For Serious Help (Attempting to Turbo)

NewZed replied to Ozzie831's topic in S30 Series - 240z, 260z, 280z

Your biggest problem might be that you're not using a meter to confirm whether things are right or not. Looks like you're just connecting wire colors and looking at the TunerStudio screen, hoping things work. In the long run, you'll be way ahead if you get a decent multimeter and learn what it's for, and how to use it. A few continuity/resistance and voltage measurements and you might not even need this thread. -

aftermarket fuel pump questions

NewZed replied to urbancustomz280z's topic in S30 Series - 240z, 260z, 280z

The fuel pump relay should be right above the handle for opening the hood, inside the cabin. It even looks like the drawing. Check to see if the original wires to power the fuel pump are still there by the pump. If so, it should be pretty easy to figure out if they can be re-connected. It may be also that everything is already connected correctly and you don't know how to cycle the pump power. Either disconnect the small wire at the starter solenoid and turn the key to Start, or turn the key to On/Run and rotate the AFM vane. Both of these actions should provide power to the pump. If you don't hear the pump it may not be a power problem, just a stuck pump. Use a meter to verify. -

aftermarket fuel pump questions

NewZed replied to urbancustomz280z's topic in S30 Series - 240z, 260z, 280z

There's a switch in the AFM and a relay that would be used to get back to factory set-up. See the wiring diagrams and descriptions in the Engine Fuel, and Body Electrical, chapters - http://www.nicoclub.com/FSM/ Since you're asking about a "pressure switch" to control fuel pressure I'll say that you should read all of the Engine Fuel chapter, before you do any work on the engine and it's fuel management system. Things will make more sense with the basics in the back of your mind while you're working. -

Everything that's used with your stock four speed will work with that five speed. That five speed is essentially identical to the four speed except for the fifth gear. You will lose the top gear switch though, that activates the solenoid for your vacuum advance. You can just bypass the solenoid to have vacuum advance in all gears. It's described in the Emissions chapter. If you replace any clutch parts, just make sure they have the same dimensions as what's on the engine now. Cheap parts that are easy to replace are the pilot bushing, and the front and rear seals on the transmission. If you're going to put a new clutch set in, you might as well do the rear main seal on the engine also, if you have the flywheel resurfaced. The super cheap swap would be to just move the shift lever over and re-use all of the old parts. You'll want to take some Scothbrite or similar to the main shaft to make sure the pilot bushing works right, and the clutch disc locates freely. Looks rusty. Don't forget to check the speedo gear. It will swap also.

-

Isn't the intercooler for NA drag-racing a bag of ice on the intake manifold? With the modern glass-filled nylon materials, you probably won't get the same effect but there are probably people cooling other parts of the intake ductwork.

-

Too high idle, found this thing; what is it? what does it do?

NewZed replied to spiff's topic in Nissan L6 Forum

Just forumizing. It's interesting to see how the path to "my engine doesn't run quite right" starts. -

Too high idle, found this thing; what is it? what does it do?

NewZed replied to spiff's topic in Nissan L6 Forum

What did the valve control? In other words, what are you giving up with your simple "solution"? -

Lug Nut Help, Acorn or Mag??

NewZed replied to AkiraZX's topic in Brakes, Wheels, Suspension and Chassis

Take a wheel in to a store. They'll probably let you test fit without buying. Make sure they don't stick out the back of the wheel or they won't clamp properly. -

Isn't inline6 saying here that WPN-062 is the diesel pump? RockAuto is selling the -079. From the info link on Rockauto - More Information for AISIN WPN079 Alternate/OEM Part Number(s): 2101017S25, 2101017S26, 2101017S27, 2101017SY7, 21010V0725, 21010V0726, BA01017S27 Edit - maybe the WP079 is special after all. The other manufacturers all list the same part number for gas and diesel but the WPN079 doesn't show as a gas engine option. AISIN doesn't even have a gas engine option (1978 280Z example) Carry on and good luck...

-

I'm pretty sure that people use the early 280Z EFI tank in 240Z's when they switch to EFI because they want the internal baffles and the bigger fuel lines for the high-flow/pressure EFI fuel pump. Should work fine for a 260Z since it's in the middle. I'm just interpolating, no actual experience with a 260Z tank.