NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Converting my car from 4 to 5 speeds?

NewZed replied to yamahondarider's topic in S30 Series - 240z, 260z, 280z

Phantom answered this in Post #7. It would be exactly like what you have until you shifted to 5th. Look through the MT chapters of the various FSM's or find a web page that lists the gear ratios for the older versus newer 5 speeds. They're different, that's why the rear gear ratio is different. -

240Z Project 1973 From 0 To Who Knows

NewZed replied to s3bastianhunt3r's topic in S30 Series - 240z, 260z, 280z

These links might help. Looks like some work ahead to get it running right. http://www.electromotive-inc.com/support/manuals.php http://www.nicoclub.com/FSM/ -

10 years after hybernation - '75 280z

NewZed replied to tamo3's topic in S30 Series - 240z, 260z, 280z

You can also put a small punch through the oil weep hole to knock the seal partially out, to get it started.- 230 replies

-

- 280z

- hybernation

-

(and 1 more)

Tagged with:

-

Converting my car from 4 to 5 speeds?

NewZed replied to yamahondarider's topic in S30 Series - 240z, 260z, 280z

1975 US cars didn't come with a 5 speed so you might spend a little time figuring out what you have. If it's a 77 Z - 83 ZX 5 speed, it will be a straight swap as beerman says. Check your rear main seal on the engine, and the front and rear seals on the transmission, they're easy to replace, pretty cheap, and you'll regret not doing it if you find they leak later. Also, on your 1976, if it's a Federal model, you'll lose the top-gear vacuum advance switch. It's described in the Emissions or Engine Fuel chapter in the FSM. Not a huge deal, but you might want to re-route the vacuum advance hose otherwise you'll never get vacuum advance of timing in the distributor. -

Tony D mentioned the 3.36 R200 in Post #2.

-

240Z Chassis Dimmensions

NewZed replied to CruxGNZ's topic in Brakes, Wheels, Suspension, and Chassis

Read the whole thread (Post 18 and 19), or make your own images (Body) - http://www.nicoclub.com/FSM/ -

The last pieces to fit are the mainshaft tip in to the pilot bushing and the alignment dowels on the back of the engine, I believe. It's also possible to jam the pilot bushing deep in to the crankshaft on some engines, although I don't know if there's an inch of space there. Were you lightly tapping or banging? Seems scary.

-

Rear Wheel Stub Axle Play - Help Needed

NewZed replied to Wheeler's topic in Brakes, Wheels, Suspension and Chassis

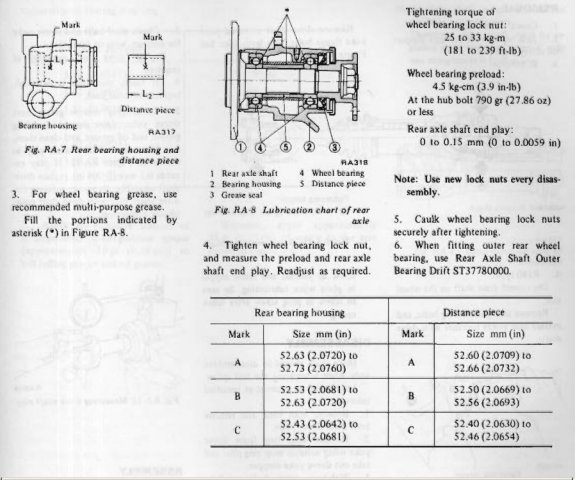

This might help. The spacer distance needs to match the housing. Don't forget that engineers design bearing assemblies for hot running, not sitting still and cold. -

Has anyone ever seen something like this before?

NewZed replied to Chuck_S30's topic in Miscellaneous Tech

Nissan stamped/etched the engine ID number in to the car's ID plate on the fenderwell up through 1976, maybe into 1977. Stopped for sure in 1978. Find the serial number of the engine, stamped on a pad at the top of the block between 5 and 6 cylinders and compare. The first three symbols are engine size - L24, 26, 28 - followed by the ID number. If it's original, it will match the car ID plate. Edit - just noticed your sig says 1974.5 260Z L28. So, if you don't have the car the engine came from, or it's post 76, you're out of luck on the ID plate. Good luck. -

Maybe it's the boot then. My 280ZX CV axles take a lot of pressure to fully compress. I haven't had them apart and didn't dig in to what keeps them extended. It's extraneous to the OP's problem anyway, shouldn't have added it. But thanks for clarifying.

-

The rubber boots on the u-joint halfshafts pull the ends together. A u-joint halfshafts natural state is on the short side so there will always be a force pulling the axle out of the diff. As opposed to the CV shafts which have a spring inside extending it. Another thing to consider is the portion of the axle that the bearing rides on. There's about an extra inch inside where the bearing rides. The axle necks down to the splines. If the axle moves too far you won't have bearing support. Which will put a lot of potentially damaging load on your Quaife unit.

-

I don't have an opinion, I just found it interesting that Leon's clearance was so much tighter than what the guys on the other thread were recommending. Quench is a fun topic. And even if Monroe (and Honsowetz) wasn't focused on quench, he's still focused on keeping parts from banging together. The point about different builds and different specs. was the main point, at the end, in the other thread also. It's all good discussion material. I've read of another way to check clearance, using a piece of solder. Stick it in the spark plug hole after everything is assembled and run the engine through a revolution. The soft solder will compress and hold its shape. Of course, the piston will be "rocked" to maximum clearance. Maybe measure the rocking distance before assembly, the do the math after. This could be one last measurement before real-world testing.

-

Here's a thread from the recent past on the piston-head clearance topic. Some solid engine builders had some interesting comments. Most recommended that you should only get close if you have the right engine components. Clearance comes in at Post #10. http://forums.hybridz.org/topic/106806-long-rod-short-piston-combo-l28-tech-questions/?do=findComment&comment=999867

-

Can you add some detail on the side-gapping and the idle changes? I just spent some effort indexing a new set of plugs,which I've been doing since I found it smoothed the idle on my last "last-legs" engine (leaky valve stems seemed to play a part in the rough idle also). I thought about side-gapping but wasn't really sure what it offered.

-

You seem to be mis-translating some modern car concepts to the old EFI systems. Rftw really just needs to break out the FSM and a multimeter and do some work.

-

Not sure why you're equating intake vacuum with leaky injectors, but 21-23 is a good number. At least you have a measurement to work with. I've seen quite a few injectors and only seen one actual leaker. And it was an external leak from a crack. Even if you had a leak, it wouldn't be so much that it floods the engine. Probably not your problem. High fuel pressure could be though. Good luck. A few more measurements would probably show the problem source.

-

It should be possible, but there are a few odd things that could be a problem. The tachometer circuit and its resistor seem to affect the ECU on some cars. There are opinions that it's not true but I've had two cars that won't run if that resistor is out. Real world results. So you'll need to study the wiring diagram to make sure that you have all the circuits you need. I installed a 280Z harness and ECU on to an engine on a stand and made it run right, it's not super-hard, but takes some time to get power to the right places. You might not even need the distributor and ignition module. You can make and break the coil circuit by grounding the negative post of the coil yourself. That's what triggers the ECU to open the injectors through Pin 1. The source of your original problem.

-

Run an extra length of fuel line between the pump and filter through the cabin by the driver's seat. With a pair of pliers squeeze the line to stop all of that extra fuel from entering the engine, as you drive. With practice, you'll probably get up to 3500 RPM. Of course, the trade-off is no more texting while driving. Worth it though, to be back on the road.

-

Take the connector off of the ECU, find the pins to the TPS, and test there to see if it's working right. Test the coolant temperature circuit also, use the chart in the FSM to see if the resistance is correct for the temperature. It will take a little bit of work to figure out which pin is which at the connector and to piece together the information from the Engine Fuel chapter of the FSM, but once you do, you'll know if the ECU is getting the right information to run the engine. http://www.nicoclub.com/FSM/

-

A thought on the use of Silly Putty - it's claim to fame is that it will flow and hold a shape given enough time but otherwise is rubbery and elastic on a short time frame. Depending on how fast you turned the crankshaft for your test, you might have had some elastic recovery. Your piston-head clearance might be even less than measured.

-

There are people on this forum who have run KYB's and Tokico springs for street use for years with no problems. I think that the rumor comes from the warning literature that KYB includes with the shocks, that says do not use with lowering springs. Boiler plate, do not use in a non-stock configuration type warning. I've had KYB's and a lower ride for about a year and a half on a street car. Tokico springs in the back, cut stock springs in the front. It rides the same, nice and firm, as when I installed them. That's on a 76 280Z.

-

Did you use a meter or just eyeball things? You need to get a voltmeter and check for voltage at the various critical spots like the coil, the starter solenoid, etc. And "turn over" means different things to different people. Engine crankshaft rotating to some, engine starting to others. More definition will help.

-

It was a nice try though. Some things are just much more difficult to do than they seem by appearance. Edit - Note that the harshest comments came from the guys that could have given the best advice. Maybe a little offended that you didn't ask before building.

-

~75% of that is solvent. So 2.25 lbs of paint per gallon, 11.25 total. The solvents are very flammable too, for anyone planning to do work inside the car. From the MSDS - http://www.plastidip.com/home_solutions/Plasti_Dip

-

L28 Rebuild cost for mechanic recommendations

NewZed replied to Bigfat280z's topic in Nissan L6 Forum

Might as well go beat the heck out of it and see if things loosen up. "Italian tune-up".