NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Re post #6 - http://www.amazon.com/ACCEL-9002C-Extreme-Universal-Ceramic/dp/B001OD2OM4/ref=cm_cr_pr_product_top Spendy in the short run but long-term might be worth the money.

-

Well, good luck then. The feeling of knowing the function of the wires and that they're connected correctly is much more satisfying, to me, than the thrill of connecting the battery or turning the key with no firm knowledge that things won't go up in smoke. But I'm kind of boring.

-

You should change the focus of what you're trying to do. Don't worry about wire colors or what this plug connects to or any of that. Sit down with the wiring diagram, the big connector to the ECU, some tape or stick-on labels and a pen, and an ohm-meter or continuity tester. Test each pin in the ECU plug for continuity to every wire end. Some of them will be pretty easy, like the pin for the CHTS should be connected to an EV1 style connector. Others might require a lot of probing. Or do it backwards and pick a wire end and just stab your probe in to every ECU plug pin until you get a hit. When you figure one out, label it with the pin number and/or (preferably and) its purpose to the ECU (example: injector ground, CHTS connection, etc). When you're done you can decide how to connect each component or power source to the proper pin at the ECU. Fuses, relays, etc. will be easier to figure out once you know each wire's function.

-

switching to carbs.what stuff do i keep?

NewZed replied to randallwayne221's topic in Trouble Shooting / General Engine

Cut all of the wires out and just add new wires as you discover things that don't work anymore. -

You need to go back and put some spaces and capital letters in those two posts. Effort returned is usually about proportional to effort invested. Too much effort is required to figure out what you're trying to say, none is left for a reply. Your problems will make more sense to you also if you describe them well. I've solved a lot of problems while trying to work up a good description so I could ask a question. In short - your jumble of words is too hard to read.

-

switching to carbs.what stuff do i keep?

NewZed replied to randallwayne221's topic in Trouble Shooting / General Engine

You know you shouldn't. Just put the work in. -

switching to carbs.what stuff do i keep?

NewZed replied to randallwayne221's topic in Trouble Shooting / General Engine

It depends on what you mean by the word "can". -

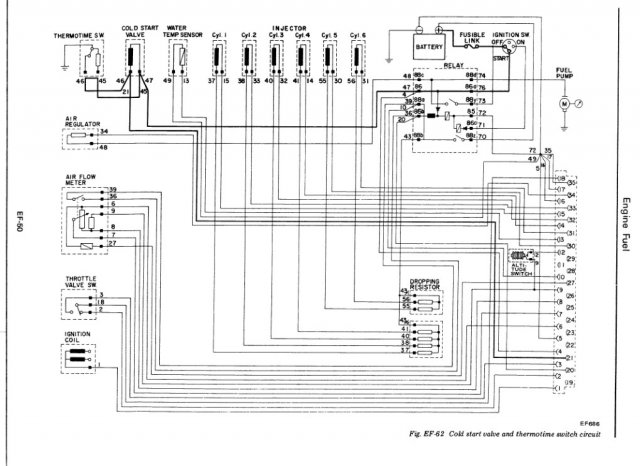

Yes, it is. For wiring issues, it's best to use the factory publications, in my opinion. Use 1983 since that's your harness, the EFI harness is essentially independent of the body harness except for power supply. When you see the page you'll understand. http://www.nicoclub.com/FSM/

-

Try the basic test of engine on/engine off. Does it shift in to gear with the engine off? The FSM shows two transmissions for 83, but only one clutch. Odds are they're the same. It's possible that the slave cylinder slipped out too far when you had it disconnected and you lost some fluid. Check the rubber boot for fluid, the reservoir for fluid level, and re-bleed the clutch. That's what I would do. If it worked once, that's a sign that you have the right parts, they're just not working right any more.

-

I think that Pin 18 is the ECU trigger from the coil negative terminal. Page EFEC-80. I would spend all of my time looking only at the diagram on EFEC-80 and make sure that everything that should be connected is, and everything that should have power does. It looks like it covers everything. Don't worry about wire colors just use a meter on the terminals. ECU connector to every component. Be aware that after you get it running with your turbo injectors it might stink like gas and foul plugs, if it stays running, because those are the wrong injectors for the ECU.

-

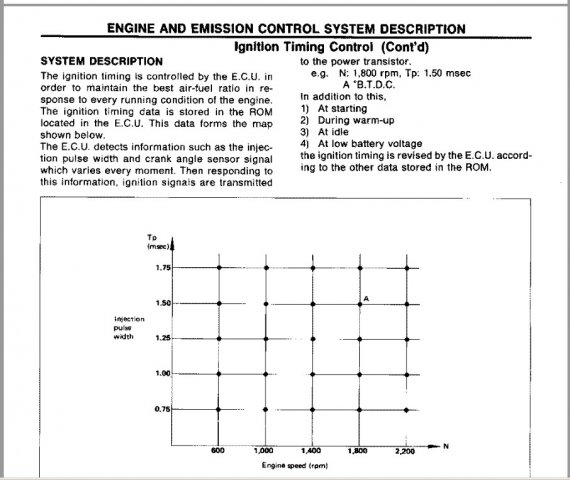

The attached picture and text is from the 1990 300ZX EFEC chapter, page EFEC-24. Maybe it has some clues. Each point is an ignition timing value, but there are other conditions used by the ECU also. Maybe the ECU is acting on an erroneous condition indication. Battery voltage, starting signal, temperature... I'm not sure what the text means by the ECU detecting injector pulse width since it is the ECU that sets injector pulse width. Probably a translation grammar error. I assume that the RB engine management is similar, they all seem to use this map from the early 90's on.

-

I have a fuel pump (not on the car now) that will run and hold pressure for about ten minutes then slowly start binding up and lose ability to hold pressure. A fuel pressure problem is more likely than a TPS problem. But the reading won't hurt you.

-

260z L28et Build (first build newb)

NewZed replied to Co0ke's topic in S30 Series - 240z, 260z, 280z

Didn't you check the timing with a light? The distributor's position determines where the rotor is when the spark happens but if the spark's not jumping to the wrong terminal (which would cause a bad miss), what tooth it's on shouldn't matter if the timing is right. Just saying, the logic seems off a little bit. -

Just verifying some things, 4 to 5 speed swap 280z

NewZed replied to yamahondarider's topic in S30 Series - 240z, 260z, 280z

One thing that might cause a bind is not lifting the car high enough to slide the transmissions out/in. Plan ahead. -

Raybestos ST43 looks expensive, for Z's - http://www.topbrakes.com/c/car-series/16541/Racing+Brake+Pads/RAYBESTOS/Raybestos+Custom+ST43/1976+NISSAN+280Z+

-

There's a pretty long thread on the forum somewhere about measuring cam specs. that suggest the numbers on atlanticz may not be completely correct. The FSM might get you closer (Engine Mechanical chapter), but there's some question about those numbers also. For increased performance purposes though, most people seem to consider the stock cams as essentially the same, compared to what you can have done by a specialist. The biggest issue with the P90 head is probably whether or not it's hydraulic or mechanical lash adjustment.

-

The throttle body just lets air in as the engine tries to pull it in. It has nothing to do with the air-fuel ratio. You may not be in the green, but the bigger throttle body will have little to do with the red. It will probably just make the motor feel more responsive, or more boggy, because it will be like stabbing the throttle from closed to wide open. It will be more switch-like, than progressive.

-

77 280z cannot start, injectors not functioning?

NewZed replied to ISPKI's topic in Ignition and Electrical

Try borini63. He parts out a lot of cars and some of them were running when he got them. Bad ECU's are not common. Pretty easy to plug and unplug also, if you can find someone to loan you theirs for a try or a pre-purchase test. -

The flywheel bolts might have threadlocker on them. Heat will soften it up and lengthen the bolts a little. Might help.

-

Removal is described in the FSM (sqwauk - FSM, FSM, sqwawk - where's my cracker?), try the Body Electrical chapter. Pictures, words, etc. You don't need to remove the dash or the glove box on a 280Z (probably not for a 240 either, no offense BD). They come out from the front after you take the AC control panel off. The screws are above the gauge face. Edit - my mistake, they do come out from below once you remove the front panel. It's pretty easy though, nowhere near dash removal level. http://www.nicoclub.com/FSM/

-

77 280z cannot start, injectors not functioning?

NewZed replied to ISPKI's topic in Ignition and Electrical

EF-55 to -57 of the FSM. There are a page and a half of testing procedures for the relay, pin by pin. Could save you some money. -

I've read accounts of people using long screwdrivers to get the tensioner re-inserted. But I've also seen accounts of lots of time wasted trying. If I was in the situation I might at least try to fabricate a tool that could be used to lift and push on it. Worth a shot. Maybe work through the access hole on the front of the timing cover so you can see better what you're trying to do. Seems like someone would make and sell a modified tensioner plate that only allows so much travel so the tensioner can't pop out. Like the one in the attached link. People would probably buy it just for insurance or ease of head work. Maybe that's why Kameari uses it. http://kameariusa.com/L6_AdjTimingChainTensioner.php

-

77 280z cannot start, injectors not functioning?

NewZed replied to ISPKI's topic in Ignition and Electrical

Pin 4 gets power during Start, along with the CSV system. Do you have a fuel pressure gauge connected? I don't see any sings that you've confirmed that the fuel pump runs and continues to run after the engine starts, -

There are pictures and descriptions in the FSM that explain cam/crankshaft coordination. There's a notch and a groove and a timing mark that tell all when combined with general knowledge of #1 cam lobe position. Align and orient four things and you'll be safe, after you get the tensioner back in to its hole.

-

question about headlight relay mod

NewZed replied to disepyon's topic in S30 Series - 240z, 260z, 280z

Unfortunately, the guy that developed the kit had a 240. Search "Zs-ondabrain" on classiczcars.com. He built the kit that MSA sells.