NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Just a guess. Wouldn't be surprised if it was like the oil pan drain plug. Internet says M16.4 - 1.33. They're also avaialble from Courtey Parts if you've got time to wait. Cheap. http://www.carpartsmanual.com/datsunS30/DatsunZIndex/Engine280Z/FuelTank/FromJul76/tabid/1622/Default.aspx

-

It's fun to guess, with little information, but if you really want some good ideas you need to add more. "My z sat for 8 months in my garage. Installed 40mm webers H7 models (completely overhualed). Installed rx7 fuel pump (producing 4psi on gauge). Installed 81 280zx distributer. (Replace oil driver and gear)" Did it run before you parked it 8 months ago? What else did you remove when you installed the Webers? and the fuel pump? and the distributor? Assuming it ran well when you parked it, odds are you just made a mistake when you did the distributor work. No reason for your rings to get messed up over 8 months. If you don't reset the distributor to factory specs. then you'll have to work around it and make it work based on principles. You'll probably understand your engine much better if you do things the second way. Or you could just start from scratch. There's a drawing the 1981 Engine Lubrication chapter showing orientation at cylinder #1 TDC. It seems to be the only drawing, for some reason, in the '81 FSM. You can at least check orientation to see how far it's off. As for the loose medal backing plate witch is concerning - maybe a promiscuous, decorated, female military member who practiced the dark arts used to own the car. lol

-

Have you measured resistance on the 9-8 and 8-6 pins? My first AFM measured high on those pins, 126 and 227 instead of 100 and 180 and the engine would only idle and go full throttle. It just popped back through the intake and bucked in between. Which, in retrospect, was probably a lean condition and 45 psi might have "fixed" it. But then it would have had a rich idle and burned a lot more fuel at full enrichment. The resistor in the coolant temp. circuit might give you a clue. It's pretty easy to do and cheap. Get an audio taper potentiometer they're easier to adjust. If it works you can decide if you want to keep it that way or get a different AFM.

-

Are you still shifting at 7,000 RPM? And you never said what fluid you were running. Bummer that it's not there yet. I was hoping. Maybe there is no good way to rebuild an old transmission to like-new performance.

-

Kind of sounds like you might have your timing light lead on the wrong plug wire or your distributor is off. If it starts and idles, you're probably in the ~20 to~ zero degree advance range. Move the timing light lead from plug wire to plug wire until you get a reading in that range then set it to 10, for starters. The cylinder that you're measuring timing on is then your new #1. If you have an adapter on your cylinder pressure gauge you'll get much lower pressure readings. If it runs you probably have much more than 70 psi cylinder true pressure. The gauge volume becomes part of what's being measured and affects the number. Just look at the difference between cylinders, if they're close, don't worry about it.

-

Look at Post #30 here, BRAAP has some thoughts on timing that might help - http://forums.hybridz.org/topic/95316-braaps-l6-efi-induction-advice-and-tips/page-2 And, from your picture, it looks like you should measure voltage not resistance, then divide by .01 to calculate degrees of advance. It says 0.01 Volts per degree right on the front panel.

-

One possibility is that you're sucking oil vapor in to the intake system through the crank vent. The PCV system is designed to move air and exhaust byproducts at a variable rate, usually low volume, through a pressure imbalance between the PCV valve and the fresh air supply in the valve cover. If the rings seat well and the valve seals are good there's not much aitr movement at all. You had it set up to pull air down through the valve cover through the crankcase, through the crankcase vent and in to the intake system at full intake manifold vacuum. That's a lot of air. You said that you applied vacuum through the through the valve cover, but it's hard to tell what that means. Might be worth studying the Emissions chapter in the FSM, or blocking the crankcase vent from the intake manifold to see if it gets better. Even if it's not the problem, I don't think that your crankcase venting system is right. It's a giant intake manifold vacuum leak, the way you've described it.

-

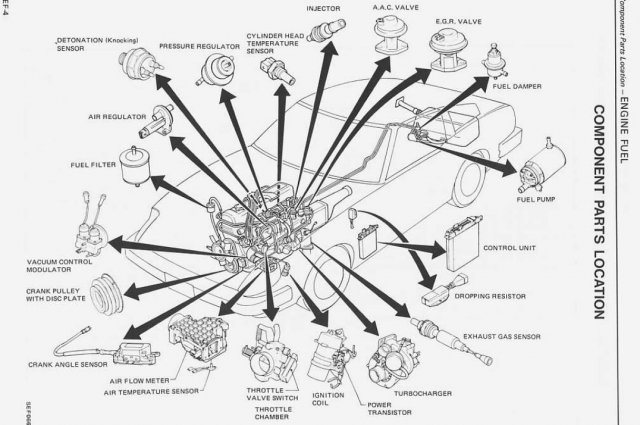

Nissan forgot to put the relief valve in the Component Parts drawing, or didn't think it belonged (they left the PCV valve out also), so the schematics were the next best place to look. Good engineering practice is to make any illustration as descriptive as possible. The drawing is misleading and could be improved. At least they showed it's general shape on EF-30.

-

I've no clue if your new design will work as intended, but I wonder if all of the welding has caused any warping. Probably worthwhile to check the manifold-to-head sealing surfaces.

-

This article from classiczcars.com might help you out - http://www.classiczcars.com/forums/content/156-s30-door-window-problems-troubleshooting-procedures.html There's a pdf file link on the page.

-

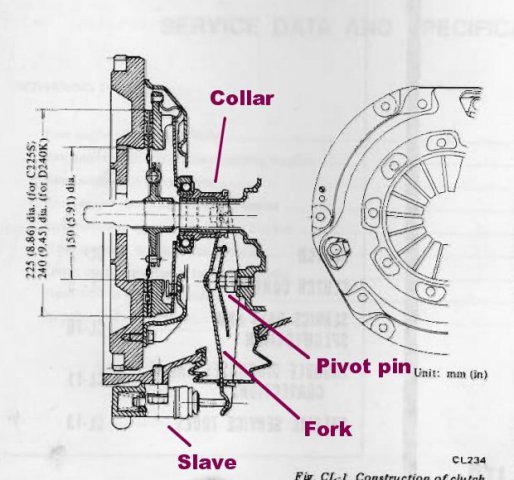

Shortening the slave rod might get you by. The sharper angle might put more wear on the bearing surfaces of the collar and fork but it might work. You said that there was some wiggle room for the collar without the slave cylinder installed. That's what matters most. Make sure that the pressure plate fingers aren't partially compressed without the slave cylinder installed. If they aren't, a shortened rod would be the way to avoid removing the transmission and starting over. To be honest, I might even try that just to know everything worked even before I took it apart to make it right. If I knew that the collar wasn't already riding the clutch. At least you'd have more to look forward to.

-

You're on hopium. As everyone is saying, there should be some play in the system. If you levered the fork to get the rod in then your slave piston is bottomed and there is pressure on the pressure plate fingers. It's like riding the clutch, you're just going to burn it up right away. The 1" of travel is probably just play in the pedal linkage and master cylinder push rod. On my car, I can reach down and push the slave cylinder rod back and pop it out by hand. It's been working great for about 35,000 miles. Force isn't necessary to put the clutch system together, even with a performance setup. Several people, myself included, have figured out that the key to matching parts is to get ~92 mm from the flywheel surface to the surface on the collar/sleeve that the fork rides on. Assuming a stock thickness flywheel. The slave cylinder, pivot pin and bellhousing mating surface always have the same spatial relationship. Edit - did you put a new bearing on the TO collar/sleeve? Maybe it's not fully seated.

-

Ben's has another thread on classiczcar. Says the motor came from an automatic car. Does anyone know what happens if you leave the spacer on the end of the crankshaft and install a flywheel on top of it? Maybe the flywheel is lifted an automatic spacer's width.

-

The brass piece is the pivot for the fork. It doesn't move. The slave cylinder pushes on one end of the fork and the other end moves the opposite way, toward the engine, pushing on the pressure plate springs. It may be that you didn't understand how the system works and have assembled it incorrectly. I got some picture editing practice in, maybe this will help. It's a cross-section so might take some study.

-

need help trying to find the idle screw

NewZed replied to wickedminded's topic in Trouble Shooting / General Engine

You're looking at the 1982 FSM? It doesn't show what the other guy has. I looked. www.xenons130.com/reference -

need help trying to find the idle screw

NewZed replied to wickedminded's topic in Trouble Shooting / General Engine

There's two, at least, really nice drawings in the FSM, one in Engine Maintenance and one in Engine Fuel. Shows a screwdriver stuck "in a hose" to adjust idle speed. Could be that someone has removed yours. -

Fuel pressure is critical. The ECU program is based on constant pressure at the injector tip. Some have run the gauge out from under the hood so they could see it while driving. You can't go wrong knowing that your fuel pressure is right.

-

Isn't the CHTS hole a dry hole? If it isn't, it's a tiny hole to the coolant passages. Wouldn't get much flow through there as-is.

-

I just tested a spare that worked well but was just a little bit rich (new MSA, swapped it for a used factory unit). 175 ohms at rest, bounced around from 175 to 250 over the range of the vane. I think that the 7-8 circuit might be the feed for the potentiometer. The ECU compares the outputs from 6 and 8 or maybe 6 and 9 to determine where the vane is, I believe. What kind of troubles are you having?

-

need help trying to find the idle screw

NewZed replied to wickedminded's topic in Trouble Shooting / General Engine

It's in a hose. -

My 280z is overheating! Please help!

NewZed replied to TheNewKid's topic in Trouble Shooting / General Engine

? Why would you do this? Reinstall a "huge leak". Are you sure that you're not just more aware of the gauge needle since it overheated? The gauges aren't very accurate. When you say it still overheats are you going off the guage reading or some actual sign of over-pressure and over-temperature? And did you remember to put the belt back on? -

Pretty sure it's in member CrayZ's "Q45 LSD tearing up cages" thread, or at least it can be figured out from what he was doing. It's a recent thread.

-

76 280z brake upgrade issues

NewZed replied to HaxMcJax's topic in Brakes, Wheels, Suspension and Chassis

You should tell what was wrong since help was offered, even if it was just a bonehead mistake. It's only fair.