NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Edited. A moderator must have deleted my other post, with its good information, in the other duplicate thread. So the comment that was here just looked like random rambling. Context, moderators, context. Consider all...

-

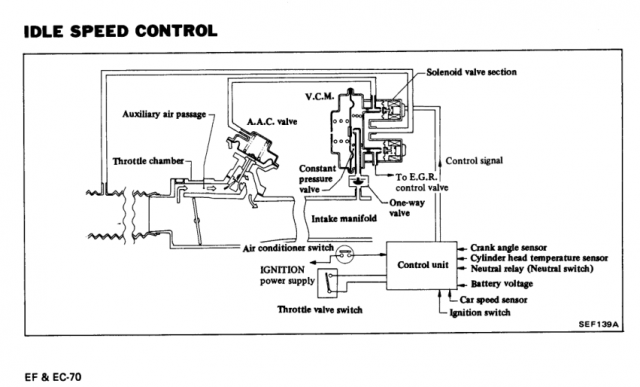

The diagram on page EFEC-70 of the 1982 FSM implies that only the AAC and VCM and a few other valves, like EGR system parts, are controlled by the ECU based on the TVS position. Not fuel. If you don't have those other devices it looks like nothing will happen.

-

Here's a list of other cars that used it, if you have to go junkyard. Watch out for 1975. 38210-N3100 http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/differential-gear/r200/37 http://www.courtesyparts.com/oe-nissan/38210n3103

-

That's a logical point. Misalignment only during acceleration. Not a lot else to go on. Assuming an LS3 due to forum name choice. And " Brand new driveshaft shop driveshaft and Hoke engine/trans mounts". Not even really clear what the Hoke parts are. http://hokeperformance.squarespace.com/store/ http://hokeperformance.squarespace.com/ls2-engine-mounts/

-

No offense intended to anybody in this thread. I think that we're all nostalgic for the more sophisticated conversations of the past. But this is just a tank, a pump, and carburetor on an engine that's been transplanted so many times that somebody wrote a book about it. The solution might even be covered in the JTR book. I don't have a copy myself, but even if it's not in there, for the Z's, there are thousands of simple electric pump to carb systems out there. That's why each pump has a full set of installation instructions and recommendations. Slow times on the old Hybridz site...

-

Still, all you need to do is measure. The pumps seem to be generally set at 7 psi. Should provide desired pressure at the carb after the pressure drop, easy to confirm with a gauge. These types of things should always be confirmed by measuring, no matter how expert the opinions are. Just like there's no best on Hybridz, there's no wrong. If it works as intended. There might be better, but saying it's wrong is wrong. Why spend a bunch of money and time if basic knowledge of pressure drops and proper installation, confirmed by measurement, get you where you need to be. Keep it simple. He's not building a top-fuel dragster, it's a simple 330 HP V8. There are hundreds out there.

-

Don't use the word modification if you're not modifying and don't want to say the same shit twice. Grammar matters.

-

Did you replace a BIP373 or did you switch from the old transistor? Kind of reads like you changed a few things along the way to the BIP373. Could be that you just never had the BIP373 installed correctly in the first place. https://www.diyautotune.com/support/tech/other/bosch-bip373-ignition/

-

The Holley should have worked fine according to instructions. Maybe you had it mounted too high and it was running dry. You should do more thinking on why the Holley failed. You might just reproduce the same errors, if not. https://static.summitracing.com/global/images/instructions/hly-12-801-1.pdf

-

You might be overcomplicating the issue. On the progression path of "work" the pump has to do, a small return line is in between deadhead and big return line. You could just add a return at the tank like Rebekahz describes and probably be fine. With a filter in front of the pump. That red Holley is rated at 97 gph if it's the one below. Might be another part of your problem. There's a bunch of calculators out there that get super specific but the rule of thumb for estimating seems to be 10 HP/gallon. Get a 40 or 50 gph pump (at 4 spi) and you'll take load off of both the pump and your electrical system. Could also be that the understandings of "deadhead" are different. No return from the carb is deadheaded at the carb. But there's usually still a regulator with a return line. If you just deadheaded the pump exit line that would be bad. Might be why it's been screaming. http://www.tanksinc.com/index.cfm/page/ptype=results/category_id=165/mode=cat/cat165.htm https://www.amazon.com/Holley-12-801-1-Electric-Fuel-Pump/dp/B00029JC5S http://www.jegs.com/i/Carter/180/P4070/10002/-1

-

Rebekahz might disagree about "wrong". He seems to do okay with his LS2 powered 240Z. There are very few absolutes in the world. http://forums.hybridz.org/topic/97623-280z-stock-fuel-tank-with-ls-1-for-dummies/ Fuel systems are easily tested with a container and some battery power. Fit your parts together, apply some power, measure what comes out of the return line. Put a 5/16" restriction on the end of the line to mimic the return port. Do some calculations. Modify if necessary. You might find that you're already overdoing it with your plan. Edit - and don't blend high pressure EFI fuel system knowledge together with carb system knowledge. Much of what's out there is about problems with high pressure systems on a 240Z.

-

Understanding the basics of an ignition system will help you solve your problem. "Dropping" new parts in will get expensive. Good luck.

-

12 volts doesn't mean that there will be enough current through the coil to make a spark. That's where the jumper wire on the negative post will tell you something. If you have the power to coil positive and you tap negative post lead to ground you'll make and break the coil circuit,just like the transistor would. If you don't get a spark that way you'll not get one with a new BIP373 either.

-

There's probably a method for testing the BIP373. That seems to where you're at. DIY says that they are the shit though. One simple test would be to see if it gets hot and shuts itself off. Touch it after trying to start and see if it's hot. You might also test the coil power circuit and spark path. Ground the coil yourself with a jumper wire on the coil negative. Be the BIP. See if you get single sparks where you should get sparks. Smart people have been known to leave the rotor off. Once you put the cap on, outofsight-outofmind. You never confirmed your rotor check. https://www.diyautotune.com/support/tech/other/bosch-bip373-ignition/ http://www.megamanual.com/ms2/bip373.htm

-

Leon mentioned the one thing that you didn't check, but assumed was right. Where the rotor points is the #1 cylinder, if all of those other things are set. Put the #1 plug wire there. You might find that one of your other plug wires actually shows expected timing for when it runs right.

-

Is it a dial-back timing light? Maybe it's not set to zero. You still have the basic problem of it runs better at 30 degrees than 10. You have two problems. When you say you're running it NA do you mean you have the NA injectors and NA EFI system? Did you have an NA engine in the car before and did it run well? You have two basic problems that might or might not be connected. Best to think about them separately.

-

Does it drive well, or just idle well? Seems like you have a running issue, and/or a measuring issue. Even if you get the distributor set to where you can adjust to 10 within its range, it will "run" better at 30. Sounds like you checked all of the right things, plus a few that don't really matter. Do you have the timing light lead on the correct plug wire?

-

It's easy to miss the L6 sub-forum. It's in its own box above all of the others in the Powertrain FAQ. http://forums.hybridz.org/forum/90-l-series/

-

Consider maintenance costs, after the build. If something breaks, how long will the car be down while you're waiting for exotic parts, if you go the exotic route.

-

Your post was funny in the way that it dramatically oversimplified the subject, and didn't really add anything of value to the thread (like this one I'm writing right now). You make it sound so easy but haven't actually done anything, that's what was amusing. The first post is very detailed and specific, with actual dollar estimates. This isn't really a bench-racing (BS'ing) thread.

-

77 280z won't stay running, no idle, out of ideas

NewZed replied to akanning's topic in Trouble Shooting / General Engine

There's only one that matters to the ECU. Check resistance at the ECU connector, as described in the 1980 Fuel Injection book. Your problem sounds like a broken or disconnected coolant temperature sender. 1977 doesn't have a CHTS. -

Front brakes keep glazing and make noise

NewZed replied to JTCN's topic in Brakes, Wheels, Suspension and Chassis

I found that only the factory shims, like the MSA shims, worked, long-term. The stick on shims just didn't work. -

Building not built. Airflow bottle neck problem. "playing around with porting the head, intake manifold, exhaust manifold will easily get me over 400whp, with a nice balanced power band." .. I know this and and I haven't even started yet. C'mon. This is the internet. Anything is possible. In our heads.

-

Front brakes keep glazing and make noise

NewZed replied to JTCN's topic in Brakes, Wheels, Suspension and Chassis

I used the Posi-Quiets and didn't like them. They're ceramic (hence my comment) and will keep your wheels cleaner and will last longer but they don't have good braking feel. Always felt like I had just driven through a puddle at first pedal press. Definitely;y not "more stopping power". And I love having the sponsors for the sites and appreciate the other parts they sell but you can get those pads for about $25 from Rock-Auto or Amazon. Beck-Arnley pads are about as close to OEM as you can get I think. https://www.amazon.com/Beck-Arnley-085-1175-Premium-Brake/dp/B00HFJC7SM/ref=au_as_r?_encoding=UTF8&Make=Nissan%7C67&Model=280Z%7C874&Year=1975%7C1975&ie=UTF8&n=15684181&newVehicle=1&s=automotive&vehicleId=1&vehicleType=automotive http://www.rockauto.com/en/catalog/nissan,1975,280z,2.8l+l6,1209204,brake+&+wheel+hub,brake+pad,1684 -

Front brakes keep glazing and make noise

NewZed replied to JTCN's topic in Brakes, Wheels, Suspension and Chassis

In a recent thread here or on another forum somebody realized that if the little right angle tab on the top of the shim is broken off you can use them on either side. The tab seems to be for installation ease. Grim's new pad idea is a good one though. I'd go with the organic material, avoid the ceramic.