NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

But the transverse links (aka control arms) set the arc of the hub and half-shaft end, so the tops of the struts shouldn't come in to play. Unless deflection of the rubber parts is different. Wish I lived in some cold snowy long winter area, with a big warm garage and one each 240Z and 280Z. I'd do some comparing.

-

You could get one for $2 at a local parts store. Funnily enough, it would probably answer your original question. A trip to the store and $2.

-

There's no vacuum under boost. And they're the stock seal, and appear to work fine. Beside that, send the seal so that ID has the dimensions. That was my point.

-

Send them one of the stock rubber seals. They're about a perfect fit for the seat, and the stock injector tip. They get slightly compressed when the injector is clamped down.

-

Also, I think that it's been shown that the axles are most compressed when the wheels are hanging, not when the car is lowered. Here's a thread, look at #18. My comments are wrong, logic-wise, I figured out later in a different thread. The arcs are different. JM, and Ross apparently, took actual measurements. http://forums.hybridz.org/topic/109669-axle-problems/ One thing that's often left out of the discussions is the amount of movement all of the stock rubber allows. Rubber diff mount, rubber suspension mounting. Maybe there's actually something else going on, not inherent to axle length but caused by too many parts moving under heavy loads. suggesting that there might be other solutions, beside axle shortening.

-

A bit sparse on facts and numbers, and there are many lowered 280Z's out there but almost no complaints about binding. I've never seen any. Seems like thee would be some 280Z's racing out there who would have felt the pull to the left or the handling problems. Not sure if that's JC commenting as Beta, or if someone else is. The issue's been discussed before. A measurement of the axle assemblies might show something. The 240Z stub and flange, bolted together, should be wider than the 280Z. If that's the cause. Easier than measuring distance between flanges, in the car. Since the track dimensions are the same, it should show up in the axle assemblies Can't ever seem to find anybody with both axle sets whenever this comes up, so it always remains unresolved. Anybody got both axle sets?

-

You can drill the manifold to fit the injector and o-ring, or or you can add injector bungs. O-rings need a certain diameter and depth of hole to seal the way they were designed to. But they can also be made to seal like a gasket would, but that's easier to do with NA. If you had the EV1 14mm injectors you could use the o-ring on the top and the stock seals on the bottom. Lots of possibilities. Look at how people did their L series manifolds, your new rail works the same way even though it's the V6.. Pallnet might have some thoughts also, since he sells the rail. You could send him a PM. https://www.google.com/search?q=injector+bungs&site=webhp&tbm=isch&tbo=u&source=univ&sa=X&ved=0ahUKEwil_KD8wMDTAhUW32MKHb92AUcQsAQIjwE&biw=1280&bih=890

-

It's gotta be the hubs.

-

Some people enlarge the manifold hole, some people devise a sealing method that works with the stock holes. With a turbo the sealing method is more difficult than NA since there's positive and negative pressure. You shouldn't really be asking about o-ring size, you should be asking how people seal 11 or 14mm injectors to a stock VG30 manifold. Injector Dynamics might already have a method. Send them a message.

-

Stronger motor mounts

NewZed replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

The transmission mount is the third engine mount. It's also designed to reduce fore and aft movement. Something to consider if you're trying to reduce engine movement. -

Buy the correct injectors, or improvise. http://store.acadianasportscars.com/fu056-0002

-

Nissan calls them "o-rings" but they appear to be the typical squared rubber seal. http://www.oreillyauto.com/site/c/detail/BWD0/274776/02524.oap?year=1985&make=Nissan&model=300ZX&vi=1209518&ck=Search_02524_1209518_-1&pt=02524&ppt=C0024#itemDetailTab_

-

P90 Head Determining If It Has Solid Or Hydraulic Lifters

NewZed replied to Mayolives's topic in Nissan L6 Forum

-

He moved it over to his Facebook page way back when. Scroll down to March 5, 2014, or try some search terms. They might work, I just scrolled 'cause I knew it was down there somewhere.. https://www.facebook.com/BetaMotorsports-LLC-143989191670/

-

-

Chicago salts their roads. Even though the seller only drives it in the summer, the rust is a big warning sign. If you can travel to pick up a car, consider checking other states, more southern or out where they use gravel, not salt. There's a nice 78 in Kansas, talked about on classiczcars.com

-

Someone on classiczcars.com has a friend who needs to have a 1981 280ZX hauled away. Better hurry. Contact info is in the first post. http://www.classiczcars.com/topic/57513-1981-280zx-turbo-going-to-the-crusher/#comment-518304 Edit - apparently it might not be free, by recent comments in the other link. Mods (the real ones) feel free to delete this thread or Tool Shed it.

-

Coilovers on Stock Length Struts

NewZed replied to ZHoob2004's topic in Brakes, Wheels, Suspension and Chassis

My car doesn't sit quite level at one inch lower and sometimes I wish I had adjustable spring perches. If you're not going too low, it's not a bad idea. You'll just bottom out sooner. You're giving up shock travel is all, in the end. Not sure what "all the way" is. Is it like "go big"? -

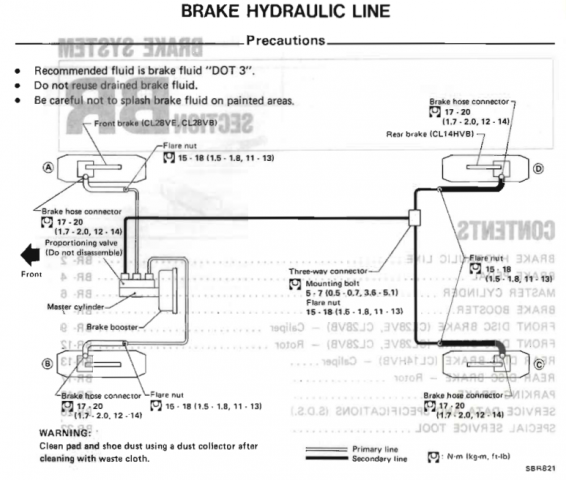

Z31 booster and MC on 240Z

NewZed replied to GIchiro's topic in Brakes, Wheels, Suspension and Chassis

It's gotta be two ports just to handle the fluid volume that the calipers use. Blocking a port should work. But, as noted, you're kind of reinventing one of many wheels. -

240z front lowering springs free

NewZed replied to mrk3cobra's topic in S30 Series - 240z, 260z, 280z

You have to be a donater to post in For Sale. They need a For Free section. -

I think this topic has come up before. The supplier apparently has a minimum run size to meet a certain price. But it might be that Whitehead and Checqucqyered are killing the product by splitting the demand. If one guy has six and another four and the cost point is ten, and they were communicating, they could combine and everybody would win. Looks lie they're not and everybody loses. And the minimum order math from the suppler is probably based on old business models where setup time was long. A modern shop with a CNC machine should be able to do one-offs for not a whole lot more than ten. Seems like these issues shouldn't really be issues. Kind of disappointing.

-

P90 Head Determining If It Has Solid Or Hydraulic Lifters

NewZed replied to Mayolives's topic in Nissan L6 Forum

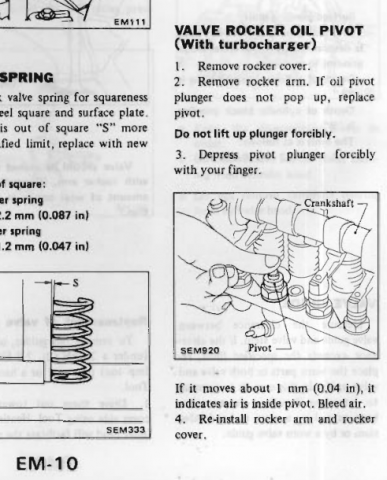

Firstly, they are not "lifters" in the GM sense. They are the pivot points for the rocker arms. There's a check procedure in the 1983 FSM Engein Mechanical chapter. Similar to your GM lifter test. -

Could be the OP doesn't know that MMS is short for Modern Motorsports. Here's Whiteheads axles. Maybe from the same place but not MMS. https://whiteheadperformance.com/product/whp-billet-cv-300zx-z31-turbo-short-cv-axle-shafts-datsun-240z-260z-280z/ Of course he says that they have his driveshaft, singular, so who knows what he's trying to say. Beware.

-

Major conflation.

-

Is there different size distributer rotors between the l28e?

NewZed replied to grillhands's topic in Nissan L6 Forum

It's not clear that you know the difference between the two, or have two different models. Better to call them the E12 or matchbox distributor, and the external ignition module distributor, or something similar. Since they're swappable and it's been 35+ years you might be looking at two ZX or two 280Z distributors.