Search the Community

Showing results for tags 'fender'.

-

I was looking around and I couldn't find much info on inner fender liners. By that I mean a plastic inner liner that closes off the front and back of the wheel well like on any modern car. This would be for better aero, and also to protect the inner fender from rocks and whatnot. Has anybody got something like that on their Z? I was thinking of going to the junkyard and trying to find something that I could make fit (once the weather improves here), but I'd love to see if anybody else has done this before.

- 19 replies

-

I am selling my 1973 Datsun 240Z. Bought as roller without engine/trans in 2011/2012. Previous owner/s have changed the roof and various parts, so some of the stuff i pulled out was off a 260z/ 280z and there might still be some mixed parts on it. That and all the modifications pretty much eliminate this as a show car. Do not buy this thinking it can be restored to show car quality. It would take far more than would make economic sense. This is purely made to run quick/fast, not to look pretty. It's raw and needs muscle to be driven. It has manual brakes without booster and manual steering without power assistance. You need to be strong like bull. But it is rewarding! If you dare you can get 0-60 in just over 4 seconds, while carrying a passenger. I've never felt the need to put effort into it, but I am certain it'll crack the 4 second mark if you just lower the tire pressure... This is a great handling, light weight car with balls! Once you get used to its noise and raw roughness or like me, fall in love with it, this car is AWESOME! Took it to tracks and autocross events and thoroughly enjoyed the @#$% out of it every time i drove it, but I am almost done building me next racecar and I need the funds to focus and finish it up... Now to the great things about this car. I'm just going to list as much as I can and I'll save some details for when you come to see it: SOLID 1997 Pontiac Trans Am LT1 V8 with 310 hp at around 5250 rpm and a torque curve that starts well above 320 ft. lbs. from the word go all the way into the rev limiter. Max torque 340 ft. lbs. Stand-alone engine harness and Howell Engineering computer, tune-able, obviously T56 manual 6-speed transmission out of the same 1997 Pontiac Trans Am S1 Sequential Shifter that translates forward/ backward motion into the H-pattern - yeah, it's awesome! R200 rear diff with a fantastic Quaife ATB torque biased helical limited slip differential upgrade and 3.545 final drive ratio Nissan Armada CV jointed half shafts LED sealed beam replacement headlights with aero covers Both, front and back bumpers lightened (not good for crash resistance, so be aware) Fiberglass bumper covers, front and back, front with lower air dam Fiberglass fenders Fiberglass hood with vents and secured by lockable aerocatch latches Fiberglass cowl Fiberglass flares Wilwood brakes (almost 13" all around) with 6 piston front calipers and 4 piston rears - high temp fluid, track disks, track pads, biasing valve installed Complete Arizona Z car suspension kit with billet control arms etc pp, which keeps the rear control arms straight while the vehicle is lowered! 5-lug Rota wheels 17x9 front and 17x9.5 rear with Nitto NT01s in 255/40/17 fronts and 275/40/17 rears Autopower bolt in 10 point roll cage NRG hub and deep dish steering wheel with quick disconnect and lockable cover Custom light weight polycarbonate dash board Dakota Digital gauge cluster with 0-60 timer and 1/4 mile timer and couple neat functions Ignition activated dash cam with GPS Corbeau racing seats on sliders, forth and back adjustable! Schroth ASM harness belts Fuel-Safe bladder fuel tank with functioning level sensor and external high flow filter and Mallory pump Fiberglass deck lid spoiler American Autowire chassis harness Clean California title Made in 1973, this car is PRE-smog and does not have to go to smog inspection! Current registration Asking price $12,500.00 Located in San Diego

- 15 replies

-

- mallory

- dakota digital

- (and 30 more)

-

I'm highly interested in buying this 260z I found on craigslist. There is nearly no rust aside from some surface stuff on the hatches. It's a pretty clean car but there is a big dent on the passenger side fender. The current owner says it was (likely) a parking lot mishap from the previous owner. My question is how much would a replacement passenger side fender cost for a 260z? How much would it cost to replace it? Thanks!

-

In 1985 I bought a new 70-78 right front fender from the Datsun/Nissan dealer in Dallas. I ended up not using it and has been stored in my shop for the last 35 years. This is the earlier gray fender, not the later black one. I am aware it is quite rare. Actually, I forgot about it until about a year ago. Used and cheap repops are going for around $200. Better quality repops and rebuilt original fenders are priced all the way up to and over $600 if you can find one. These have not been available for a number of years. Any qualified help on price would be deeply appreciated. I want to find this guy a new home. Look closely, no dents just some mild box/shelf wear.

-

I have the fenders off from my '76 280Z for some rust repair. There are some pads that support the outer fender that appear to originally have been covered with some kind of foam or padding. Does anybody know what this was originally, or what could be used as a replacement?

-

Hey Everyone, After months and months of consideration, my 1976 280z is getting a new life. I've had this car for 2 or 3 years and have had it mostly running, but keeping finding small anomalies that turn into more and more fixes, and more questions about what the POs were trying to do with it. Well, my OCD has had enough and it's time for me to know every square inch of this car and have it the way I want it. I'd like to share this project no matter how it turns out, whether it helps someone else, or any of you all want to throw in your 2 cents - I would appreciate some veteran knowledge. Wants: 300+bhp, decent handling, decent brakes, keep it classy looking with exception to wide-body mostly for grip, mostly stock looking interior with sound deadening and added comfort, a much cleaner wiring layout that's color-blind friendly. To achieve all this, I was initially trying to decide between an S54(M3) or LS swap. After some research I'm definitely leaning towards LS with my skill level and budget. I know there's nothing original about it, but I have enough battles to fight - I'm going to keep this part easy. I'm still debating between the 280yz or Subtlez kit, and may likely do YZ rear and Subtlez front - I'm not sure I really want to be running 10-12" wheels square. Budget? I don't have a solid number, mainly because I will take my time to do this right. IF this were to creep over $20k, I'm doing something wrong basically. I know there will be "while you're in there" costs, like bushing kits etc. At the moment I'm just tearing it all down and organizing everything in a separate room with bags and labels. I have some unknowns at this point to digest until I get to them - how I want to remove the paint (grind, sandblast, etc), sound deadening (dry ice chisel, sandblast?), and any remaining adhesives/insulation (sandblast?, chemical?). I read sandblasting the exterior could cause some warping issues, but I haven't dug that deep on that specific subject yet. Anyway, I'll keep this updated, and hope to learn a lot and help anyone else doing this as well. Thanks

-

I need a fender for my 280zx that I am restoring. Preferably rust free. Willing to negotiate on price based upon the condition of your fender.

-

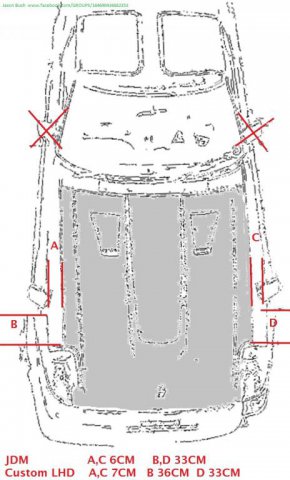

Greetings. With the lack of a Fender Mirror template for S130 on Google Image search, thought I'd make one, submit it, and let the Interwebz do its thing. These are two sources of Mirror locations I've gotten. Anyone really disagree? Thanks for any input.

-

I am trying to fit 28X10.5" slicks under my 240z. I spent a lot of time talking to folks who have installed screw-on flares only to have to re-cut due to not cutting enough the first time. I put them high-higher than most (and I hope I like it), but I got to this point working with MiKelly who cut a tire road racing and had to re-cut at least once. The top of the flare is 4" below the hard bend in the quarter panel near the rear of the quarter window. The following are photos from the hot rod shop doing the metal work for me while I'm out of town. The metal man is being great about sending me photos. This is not a custom car, this is a race car, so I'm interested in not cutting a tire. I do not offer these photos as the best way to install flares; rather I only hope to share what I have learned and what I'm doing. I forgot to take my slicks to the metal man for test fit, so that has me stalled for now, but I called back from vacation and a good friend is delivering them in the morning. I need a lot of metal taken out of the dog leg section. I will include a photo of my car squatting on launch wearing 26X8.5 slicks-note how close the tire is to the dog leg. Test mounting the big slicks should answer the question of whether he has removed enough, or if I need him to remake the forward portion of the wheel tub/inner fender. SunnyZ solved this clearance problem by totally redesigning his rear suspension to move the tire rearward 1 full inch. I'm not about that. If push comes to shove, I will go to 27" slicks, but there isn't a lot available in that diameter. More photos when I have them. I made one obvious mistake in locating my flares but I'm pushing forward. When you test fit your flares, make sure the car is level. I test fit with the rear of the car high on jackstands and the front tires on the ground and used a plumb bob to locate the center of the flare over the center of the hub. That resulted in a flare that is rotated rearward somewhat once the car is on level ground. I wish the front of the flare was farher down, but I'm moving on. I will try to stick with the small screws that come with the Z-force Productions flare mounting kit and delay the placement of rivet nuts (which puts a BIG hole in the sheet metal). I may be looking at a paint job this winter (especially if the welding burns my paint up terribly), in which case, I will have the current small holes welded and then rotate the flare and redrill it as it should be.

AC3_7245_May2017_CaliPhoto.thumb.jpg.a22e35927a400e7f0fb8a881edd20b5a.jpg)